Preparation method of low temperature expandable graphite/polymer foam material

A technology of expanded graphite and foaming materials, which is applied in the field of preparation of low-temperature expandable graphite/polymer foaming materials, can solve the problems of long storage time, high cost, gas collapse and foaming, and achieves foaming and molding. The method is simple, low cost, and the effect of solving the problem of gas distribution and escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

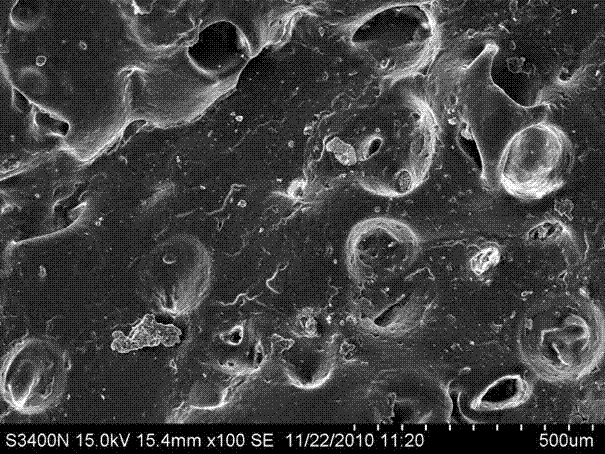

[0022] Choose 50-mesh low-temperature expandable graphite, bake low-temperature expandable graphite and PP (MR=0.36g / 10min) in an oven at 60°C for 3 hours, and mix the low-temperature expandable graphite and polypropylene at a weight ratio of 15:100 to prepare Obtainable PP. Put the sample prepared above into a silicone oil bath at 210°C for foaming. The measured density is 0.66g / cm 3 . Scanning electron microscope picture as figure 1 shown.

Embodiment 2

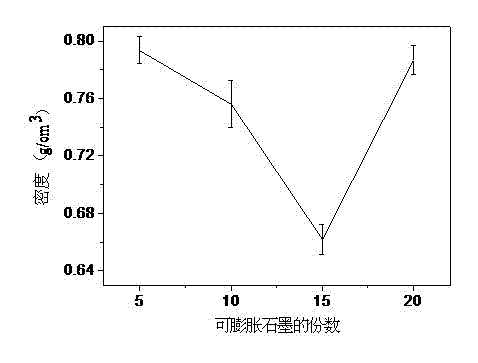

[0024] Choose 50-mesh low-temperature expandable graphite, bake the low-temperature expandable graphite and PP in an oven at 60°C for 3 hours, and then add 5, 10, 15, and 20 parts of low-temperature expandable graphite per 100 parts by weight of PP to make a mixture, which is Explosive PP. Put the sample prepared above into a silicone oil bath at 220°C for foaming. The density was measured, and the experimental results were as follows figure 2 shown.

Embodiment 3

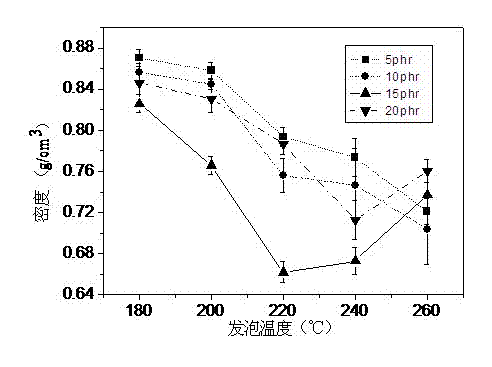

[0026] Choose 50 mesh low-temperature expandable graphite, add 5, 10, 15, 20 parts of low-temperature expandable graphite per 100 parts of PP to make expandable PP. Put the sample prepared above into a silicone oil bath at 180°C to 260°C for foaming. The density was measured, and the experimental results were as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com