A kind of room temperature vulcanized silicone foam sealant with high temperature resistance and heat insulation and preparation method thereof

A technology of foam sealing and room temperature vulcanization, which is applied in the field of silicone sealants, can solve the problems of high temperature resistance, low thermal conductivity, and single product structure, and achieve the effects of low thermal conductivity, stable cell structure, and improved high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

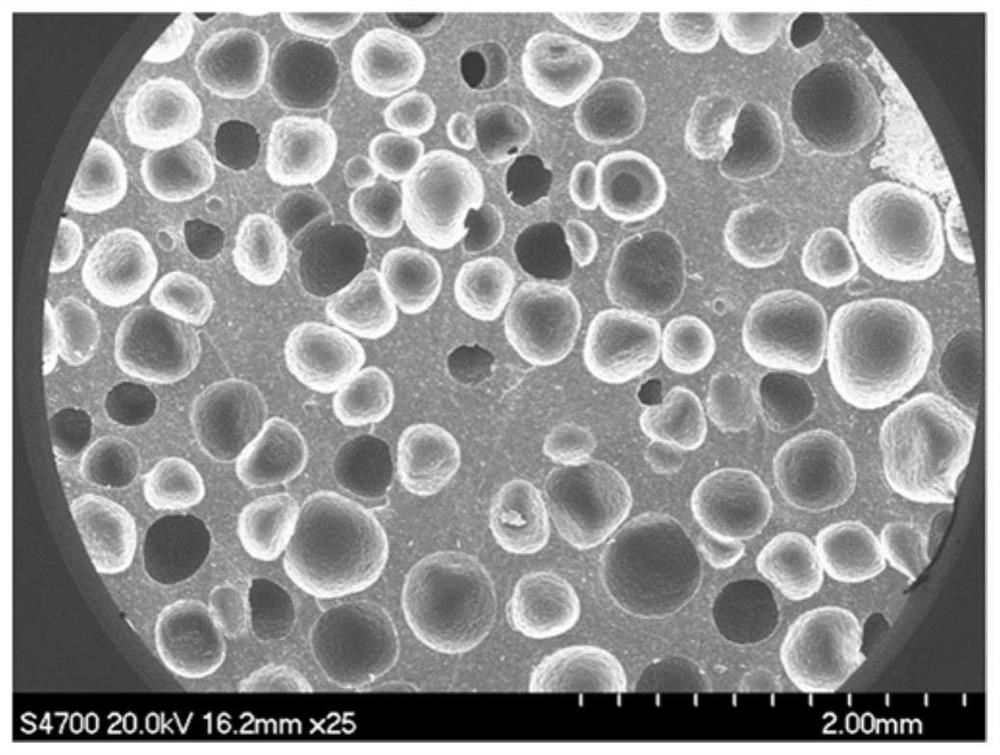

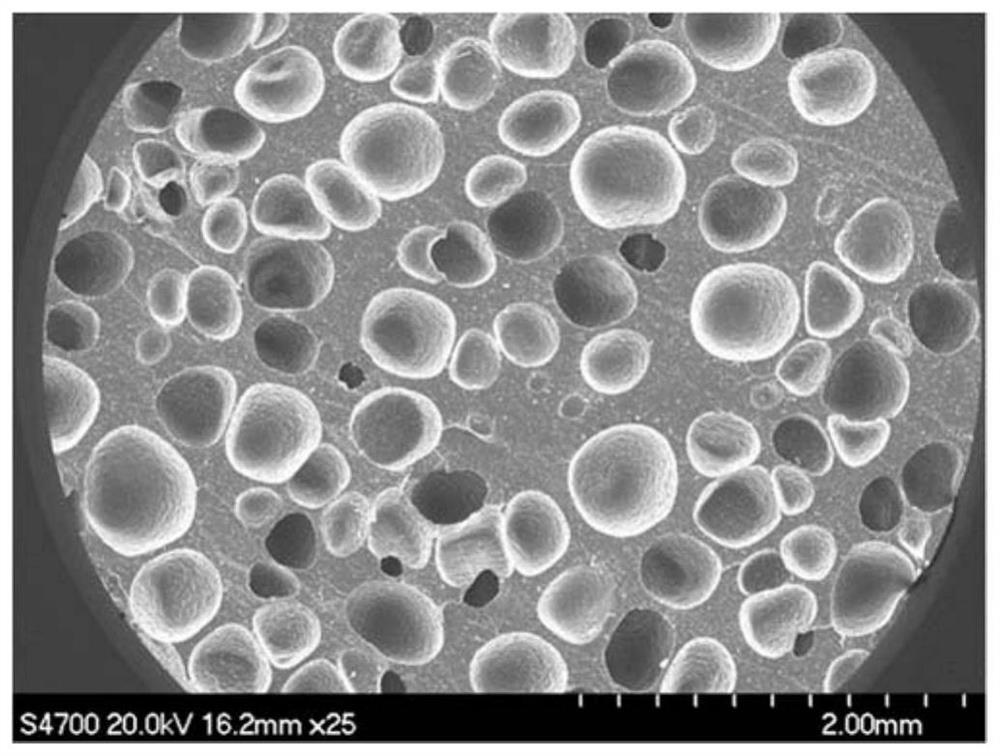

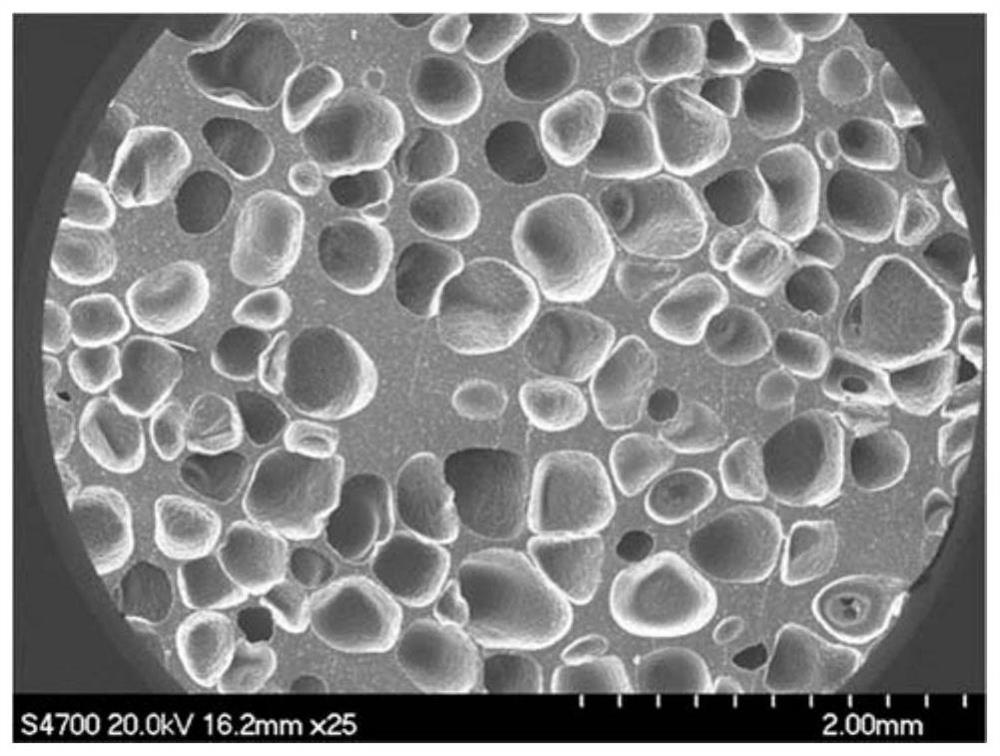

Image

Examples

Embodiment 1

[0061] The silicone resin in Example 1 is MQ silicone resin, purchased from Shanghai Aishibo Organic Silicon Material Co., Ltd., model MVDQ-3, viscosity 7800mPa.s, vinyl content 3.13%;

[0062] The silicone resin in Examples 2 and 3 is a spiral-shaped silicon-titanium resin, which is self-made in the laboratory; the preparation method refers to the literature: Wu Jianhua. Synthesis and characterization of a spiral-shaped silicon-titanium resin [J]. China Adhesives, v. 26(11):1-4;

[0063] The silicon resin in the fourth and fifth examples is a cruciform silicon-titanium resin with benzene rings in the main chain, which is self-made in a laboratory, and is prepared with reference to Example 1 in CN103408763A;

[0064] Methyl hydrogen-containing silicone oil was purchased from Shandong Dayi Chemical Co., Ltd., and its molecular formula is: (CH 3 ) 3 SiO[(CH 3 )(H)SiO] n Si(CH 3 ) 3 , model DY-H202, hydrogen content is 1.6%;

[0065] The inhibitor was tetramethyltetravinyl...

Embodiment 1

[0069] A room temperature vulcanized silicone foam sealant, comprising A component and B component; wherein, A component includes the following raw materials in parts by weight:

[0070]

[0071] B component comprises the raw material of following weight portion:

[0072]

[0073] The preparation method of the above room temperature vulcanized silicone foam sealant comprises the following steps:

[0074] (1) Put quartz powder, carbon black, and zinc oxide into an oven, heat up to 100°C, and dry for 3 hours;

[0075] (2) Weigh the raw materials of component A according to the above ratio, put the raw materials except the inhibitor into the enamel dish for pre-mixing, then add the inhibitor to obtain component A;

[0076] (3) Take the raw materials of the B component according to the above proportioning ratio, put the raw materials except the platinum catalyst into the enamel dish for pre-mixing, then add the platinum catalyst to obtain the B component;

[0077] (4) Then...

Embodiment 2

[0081] A room temperature vulcanized silicone foam sealant, comprising A component and B component; wherein, A component includes the following raw materials in parts by weight:

[0082]

[0083] B component comprises the raw material of following weight portion:

[0084]

[0085] Refer to Example 1 for the preparation method of the above room temperature vulcanized silicone foam sealant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com