2,5-furandicarboxylic-acid-based polyester foam material and preparation method thereof

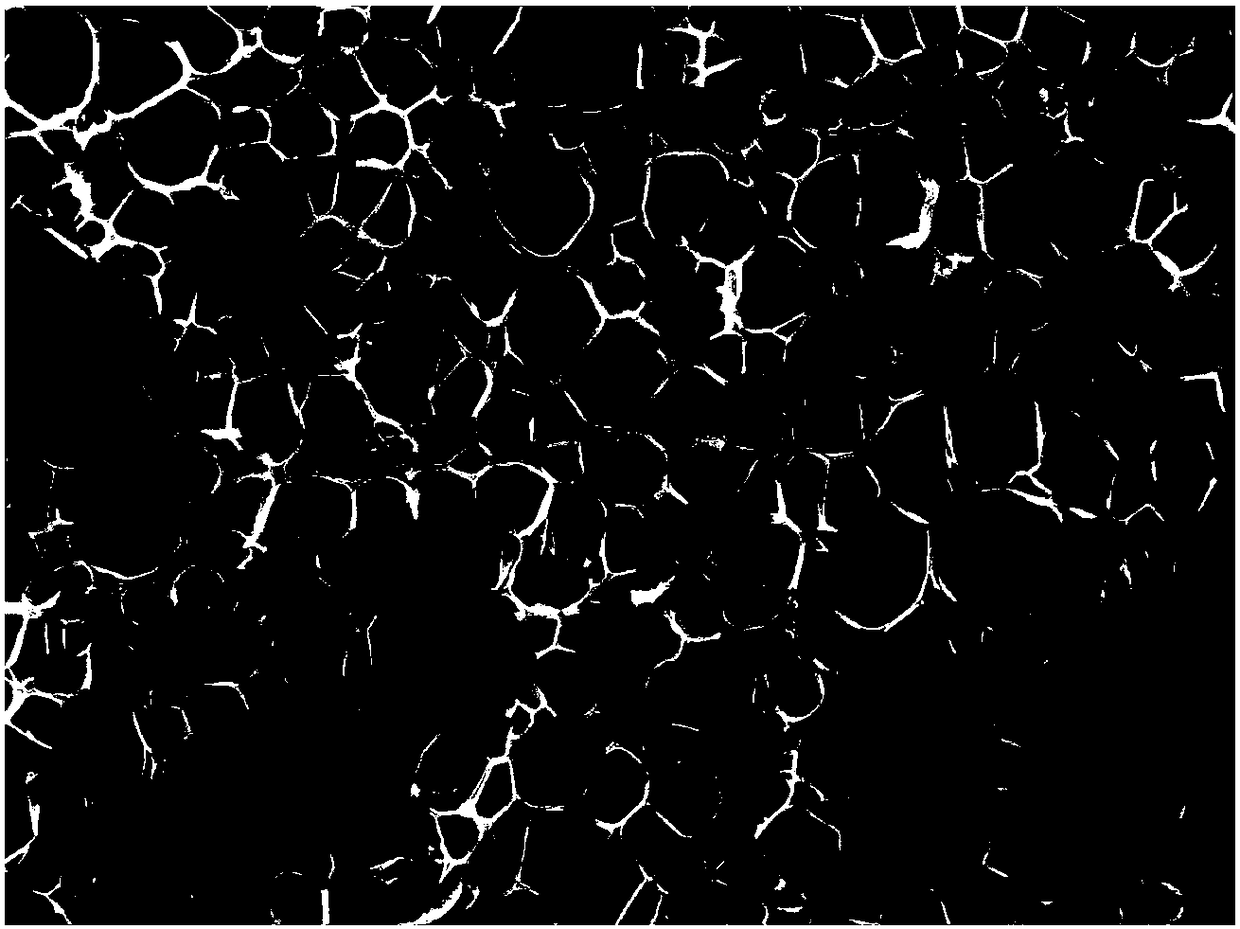

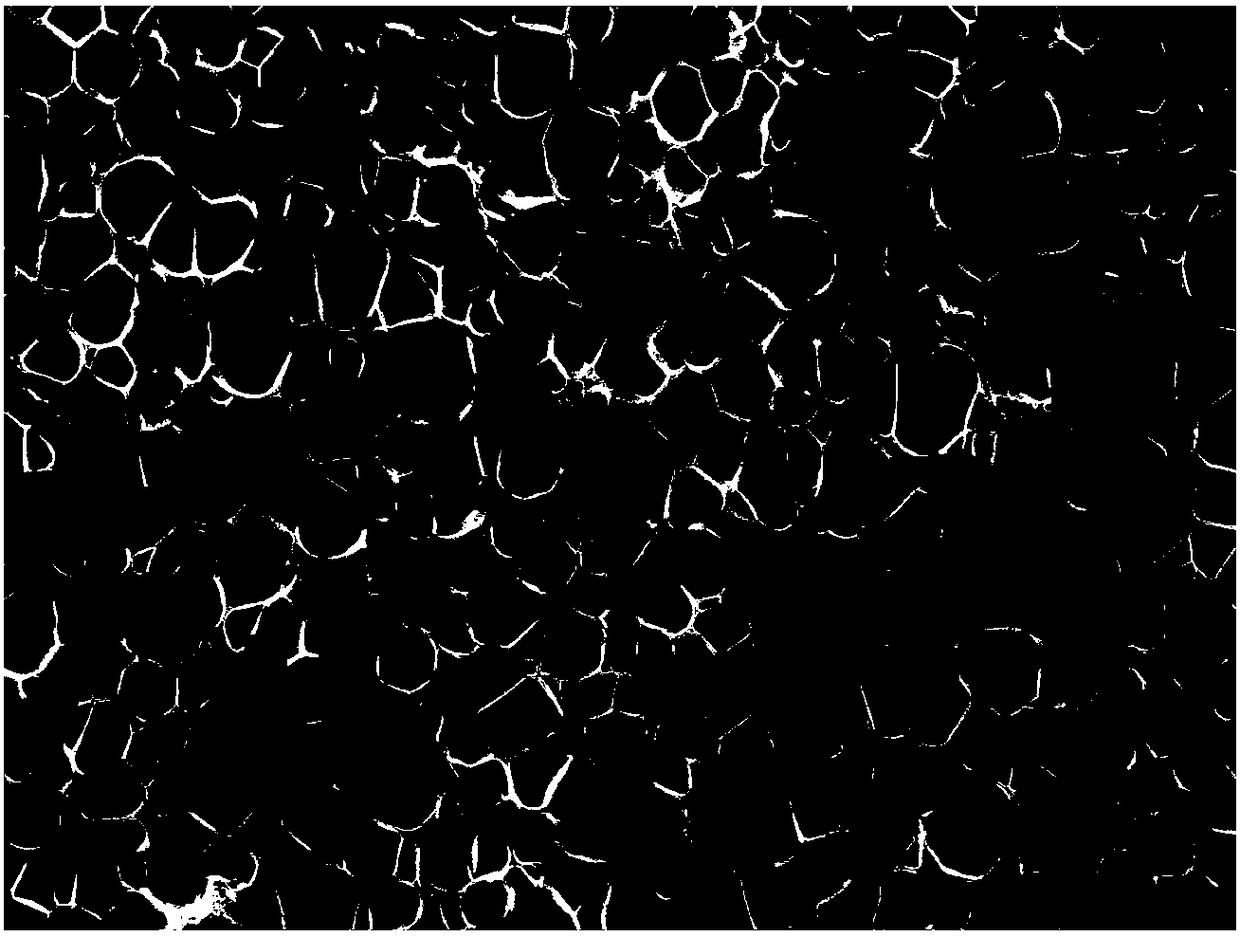

A technology of furandicarboxylic acid and foaming materials, applied in the field of polymer foaming materials, can solve the problems of slow dissolution rate, low solubility, poor foaming performance, etc., and achieve improved toughness, appropriate expansion ratio, and uniform cell size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of 2,5-furandicarboxylic acid base polyester foam material provided by the invention comprises the following steps:

[0023] (a) placing 2,5-furandicarboxylic acid-based polyester plastic in a mold, and pressing it into a sheet-shaped preform, and then quenching the sheet-shaped preform;

[0024] (b) placing the quenched preform and the first foaming agent in a closed container; wherein, the first foaming agent is not in contact with the preform, and the first foaming agent is At least one of chloroform, acetone, ether, pentane, and hexafluoroisopropanol;

[0025] (c) feed a second blowing agent into the airtight container again, the second blowing agent is at least one of carbon dioxide and nitrogen, and keep the temperature in the airtight container at 40°C to 65°C , so that the first foaming agent changes from a liquid state to a gaseous state, while maintaining the pressure in the airtight container at 1 MPa to 6 MPa, and the pressure holding...

Embodiment 1

[0042] The PEF plastic granules are placed in a vacuum oven, and dried at 70°C for 10 hours to remove the moisture in the PEF plastic granules, so that the water content of the PEF plastic granules is ≤0.05wt.%.

[0043] Then put the PEF plastic particles in a mould, and press it into a thin plate-shaped preform with a thickness of 1mm on a molding machine at 220 ° C. The thin plate-shaped preform is in a molten state, and then the preform in a molten state in the mold Together with the mold, place it in liquid nitrogen for quenching treatment for 5 minutes to obtain a quenched preform.

[0044] Place the quenched preform and the beaker containing ether together in the autoclave without contact, and use 1 mL of ether for every 50 g of the preform. Set the temperature in the autoclave to 45°C to vaporize the ether, and at the same time fill the autoclave with carbon dioxide gas to keep the pressure in the autoclave at 4 MPa for 5 hours.

[0045] Quickly remove the gas in the a...

Embodiment 2

[0048] The PEF plastic granules are placed in a vacuum oven, and dried at 70°C for 10 hours to remove the moisture in the PEF plastic granules, so that the water content of the PEF plastic granules is ≤0.05wt.%.

[0049] Then put the PEF plastic particles in a mould, and press it into a thin plate-shaped preform with a thickness of 1mm on a molding machine at 220 ° C. The thin plate-shaped preform is in a molten state, and then the preform in a molten state in the mold Together with the mold, place it in liquid nitrogen for quenching treatment for 6 minutes to obtain a quenched preform.

[0050] Place the quenched preform and the beaker containing ether together in the autoclave without contact, and use 1 mL of ether for every 50 g of the preform. Set the temperature inside the autoclave to 45°C to vaporize ether, and at the same time fill the autoclave with carbon dioxide gas to keep the pressure inside the autoclave at 5 MPa for 5 hours.

[0051] Quickly remove the gas in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com