High-elasticity and uniform-cell size foamed rubber hose composition for charging roller and preparation method of foamed rubber hose composition

A technology of cell size and rubber foaming, which is applied to tubular objects, applications, household appliances, etc., can solve the problems of complex production process, insufficient vulcanization degree, high energy consumption, etc., and achieve long scorch time, fast vulcanization speed, and surface The effect of high smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

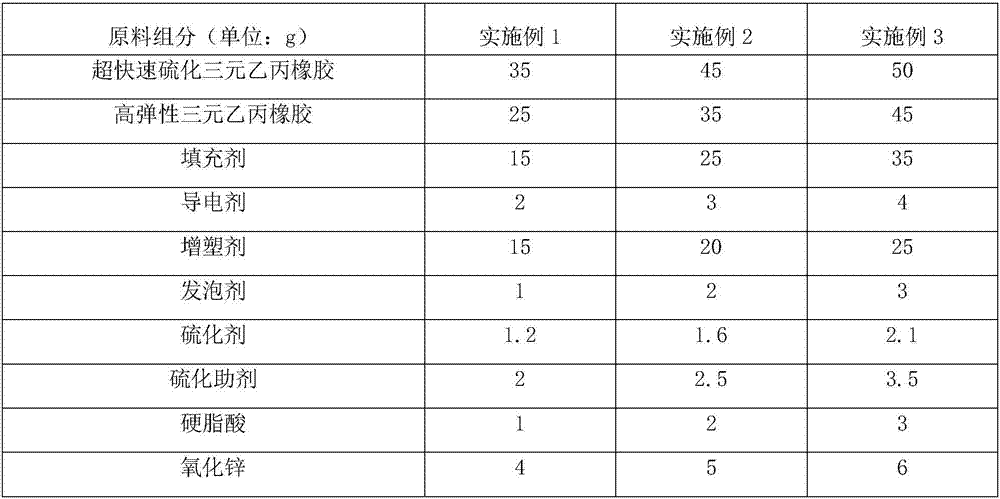

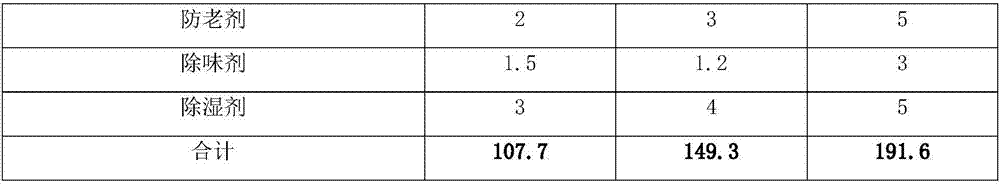

[0035] The technical solutions of the present invention will be further described below in conjunction with specific examples.

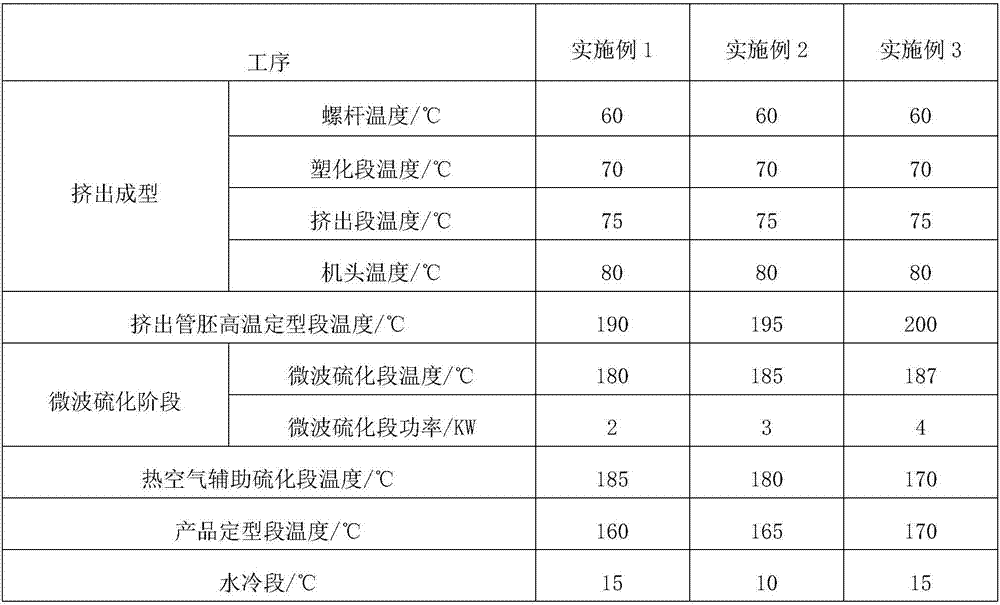

[0036] The formula of the rubber foam hose for charging roller with high elasticity and uniform cell size in Examples 1-3 is shown in Table 1, and it is prepared by the following method: adding ultra-fast vulcanized EPDM to the internal mixer at the same time Propylene rubber and high elastic EPDM rubber, stir and heat for 50-70s, add zinc oxide, stearic acid, foaming agent, deodorant, anti-aging agent and dehumidifier, continue mixing for 30-40s, add filler Mix with plasticizer, continue to stir and heat for 100-120s, when the temperature reaches 90°C, add vulcanizing agent and vulcanization aid, continue stirring, when the temperature of the internal mixer reaches 105-110°C, stop stirring and heating, deglue The obtained mixed rubber is thinly passed on the open mill for 3 to 5 times to produce a rubber strip. After the rubber strip passes through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com