Patents

Literature

113results about How to "Increased degree of vulcanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant rubber sealing ring for automobiles

The invention discloses a high-temperature-resistant rubber sealing ring for automobiles. The high-temperature-resistant rubber sealing ring comprises the following raw materials in parts by weight: 70-90 parts of ethylene-propylene-diene-terpolymer rubber, 10-30 parts of chloroprene rubber, 1-4 parts of an anti-aging agent, 0.8-1.5 parts of active zinc oxide, 0.2-0.4 part of magnesium oxide, 0.5-1.0 part of calcium oxide, 0.6-1.5 parts of butyltin mercaptide, 30-40 parts of modified kaolin, 10-15 parts of magnesium methacrylate, 1-3 parts of a promoter, 6-10 parts of soybean oil, 1-2 parts of ethyl methacrylate, 40-80 parts of paraffin oil, 0.2-0.5 part of triallyl phosphate, 1.0-1.5 parts of a crosslinking agent BIBP, 0.5-1.2 parts of an assistant crosslinking agent TAIC, 0.3-0.5 part of microcrystalline wax, 2-3 parts of a vulcanizing agent and 0.5-1 part of phthalic anhydride. The sealing ring disclosed by the invention has strong weather resistance, corrosion resistance and ozone resistance, and can be suitable for being used as the high-temperature-resistant rubber sealing ring for the automobiles.

Owner:TONGLING SANSHENG ELECTRONICS

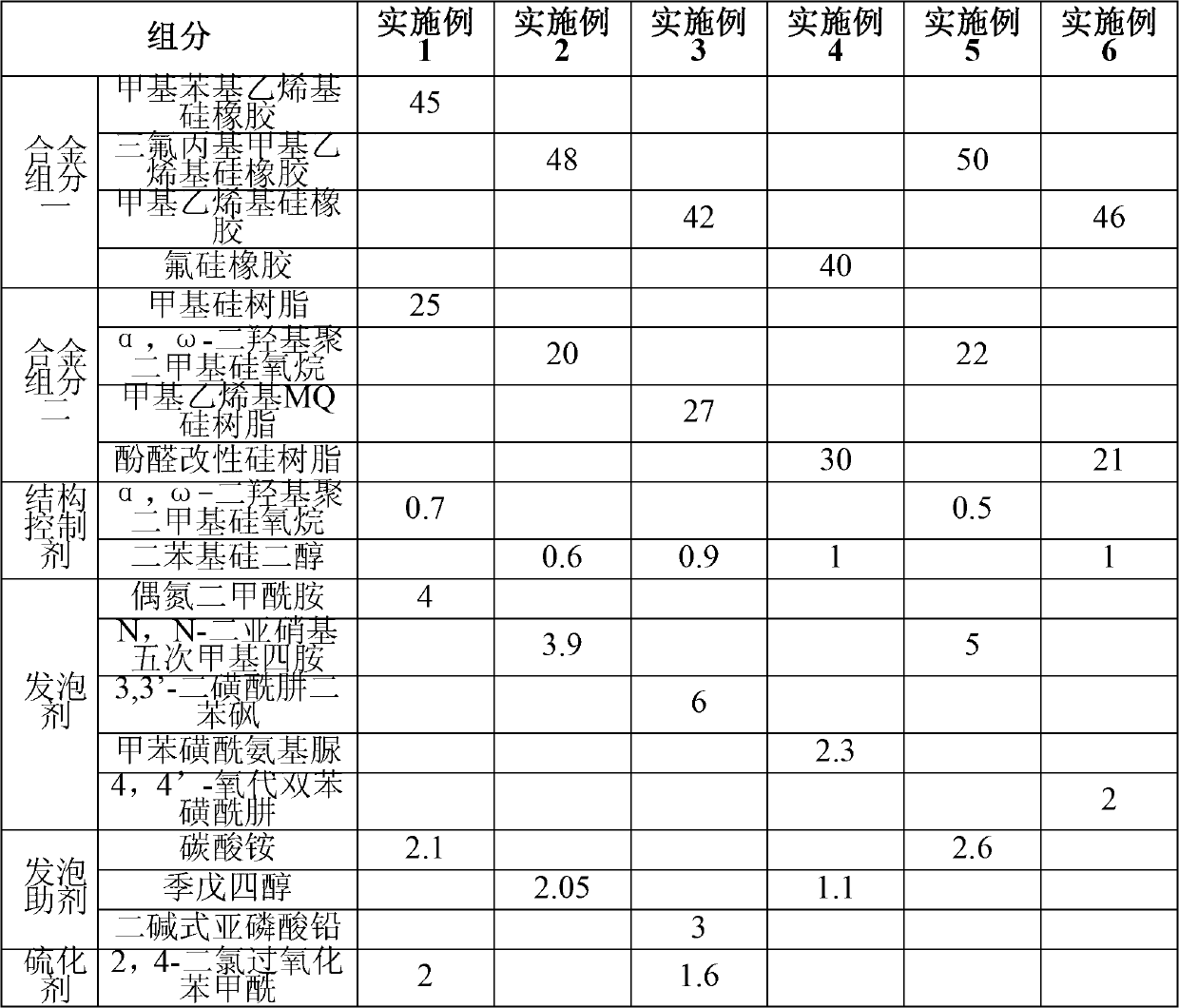

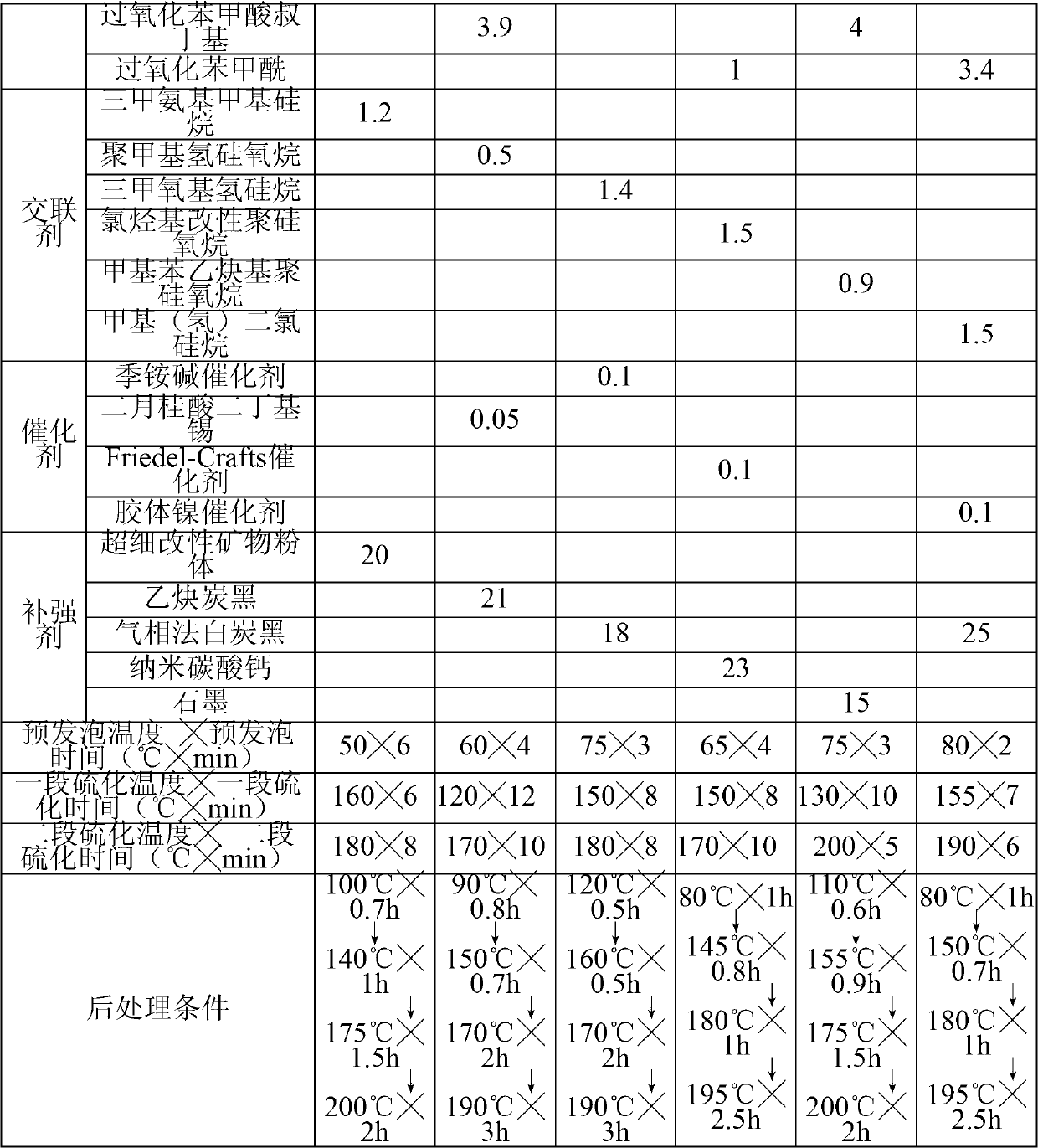

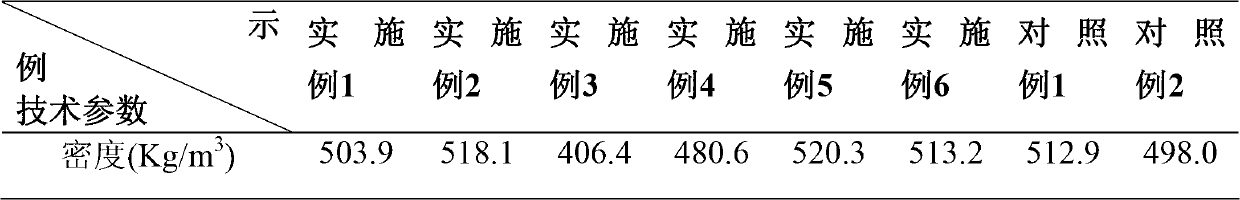

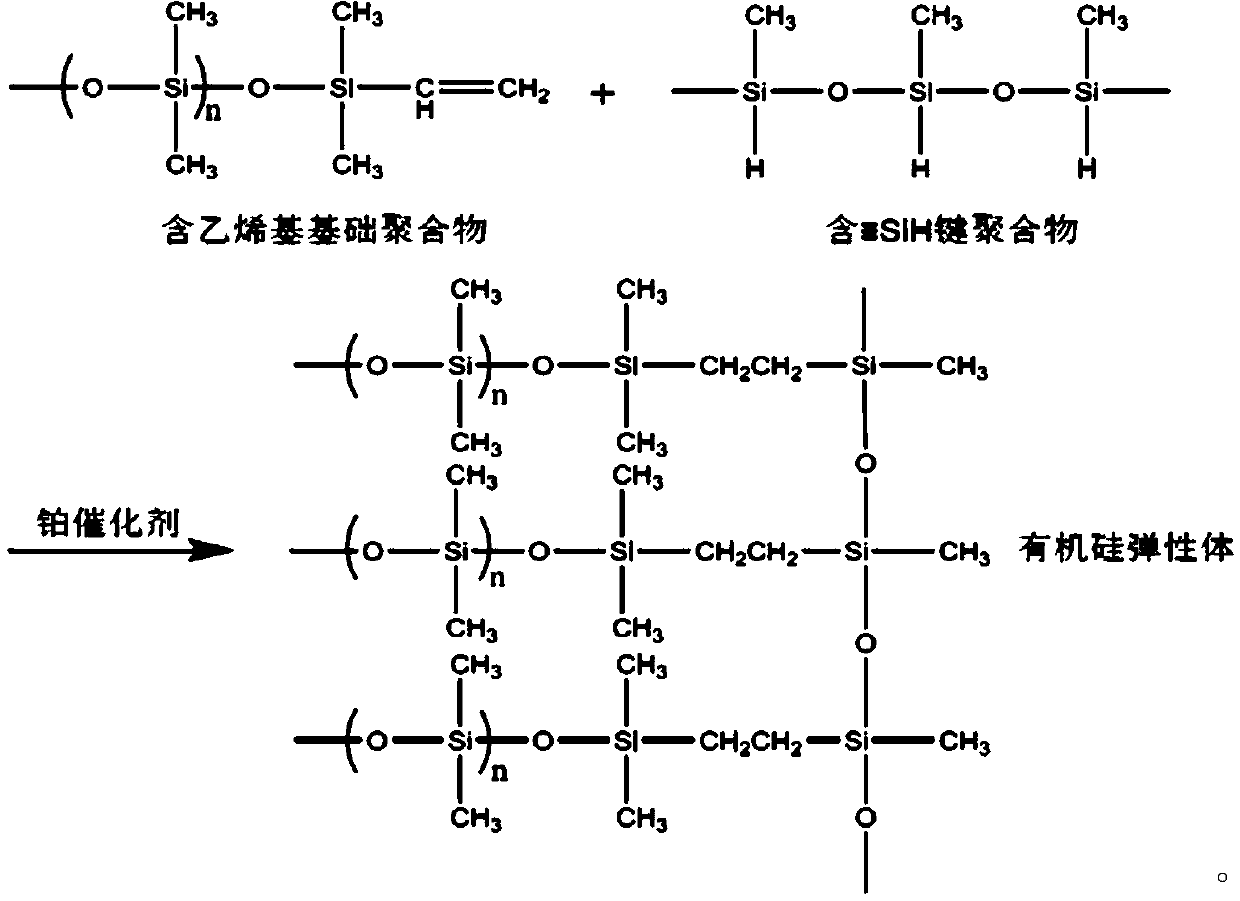

High heat-resistant porous organic silicon alloy elastomer material and method for preparing same

The invention discloses a high heat-resistant porous organic silicon alloy elastomer material and a method for preparing the same. The method comprises master batch preparing: weighing 40% to 50% of alloy component one, 20% to 30% of alloy component two, 0.5% to 1.5% of cross-linking agents, 0.5% to 1.5% of constitution control agents, 15% to 25% of reinforcing agents and 0.05% to 0.15% of catalysts to be fully mixed, and allowing the mixture to stand for 2 to 4 hours; mixing: adding, by weight, 2% to 6 % of foaming agents, 1% to 3% of foaming assistants and 1% to 4% of vulcanizer into the master batch to be mixed for 10 to 30 minutes; vulcanization and foaming: vulcanizing and foaming rubber compound, and cooling and domolding after two phases of reaction; and post-processing: obtaining the high heat-resistant porous organic silicon alloy elastomer material after three phases of stoving. The high heat-resistant porous organic silicon alloy elastomer material has the advantages of low density, high softness, ductility, elasticity and porosity, and good physical properties of mechanical shock or impact absorption and high frequency damping. The material can be used continuously for a long time at a high temperature, is inflaming retardant, and can be widely applied in the fields of industry, agriculture, communication, military, construction, daily articles and the like.

Owner:XIAN UNIV OF SCI & TECH

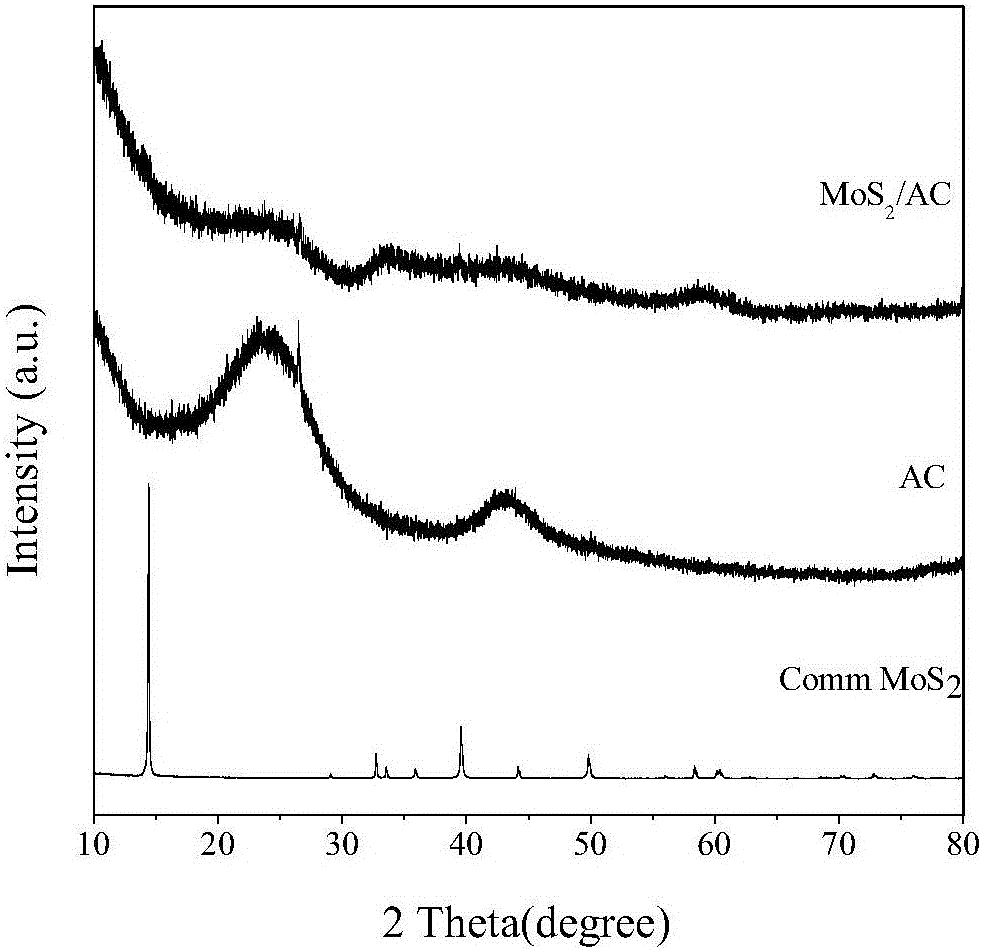

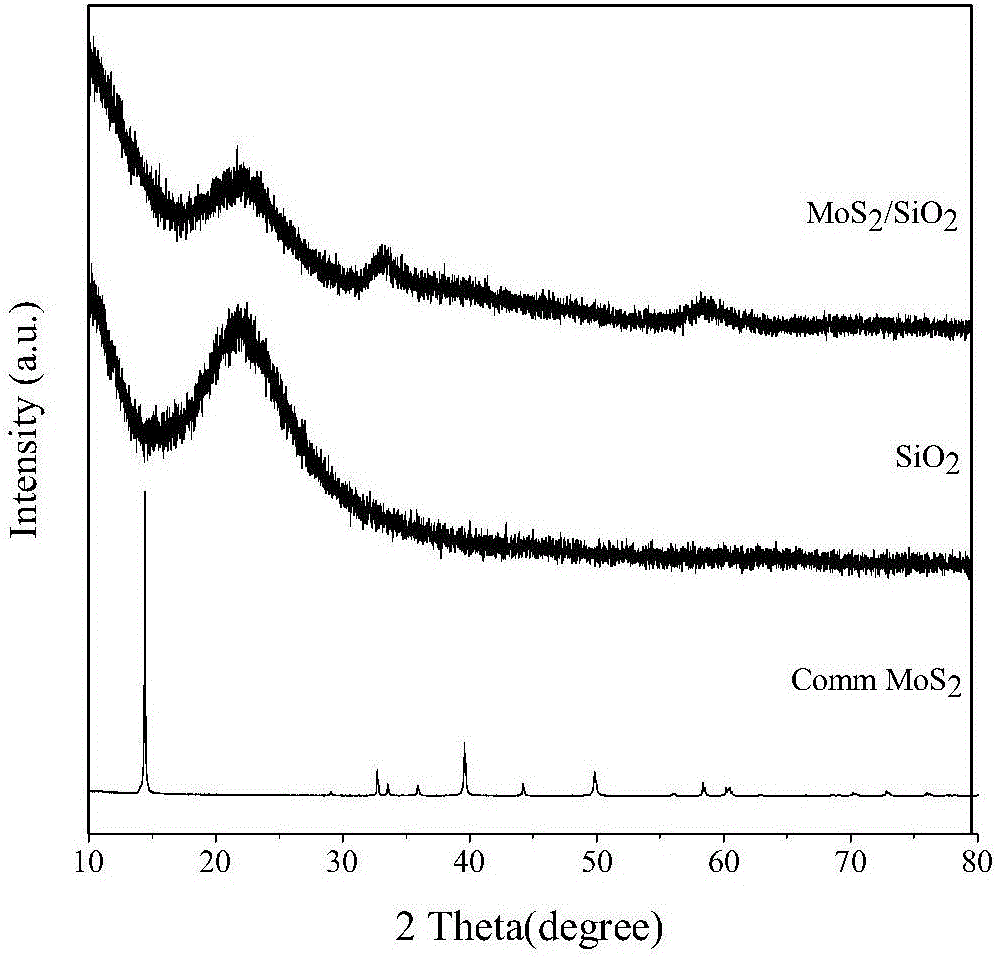

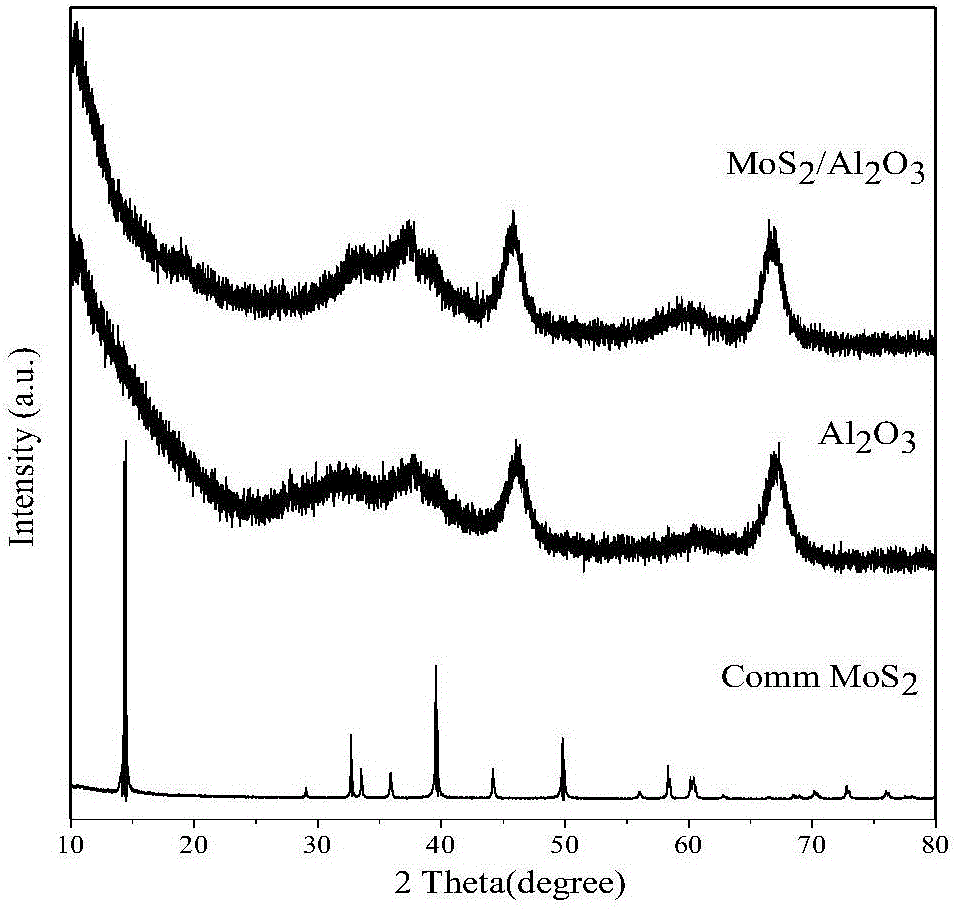

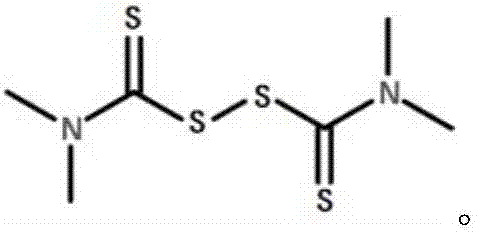

Loaded type high-dispersion molybdenum sulfide catalysts and preparing method thereof

InactiveCN106111163AEvenly dispersedEasy to operateCatalyst activation/preparationCarbon fibersCarbon nanotube

The invention discloses a preparing method of loaded type high-dispersion molybdenum sulfide catalysts. According to the catalysts, molybdenum sulfide serves as the main active ingredient, one or more of nickel, cobalt, iron, copper, platinum, ruthenium, rhodium, palladium, lanthanum, osmium, iridium and the like can be added as a second metal component, and the components are loaded on a carrier selected from active carbon (AC), carbon black (VB), carbon fibers (CF), graphene, carbon nanotubes (CT), a mesoporous carbon material, gamma-aluminum oxide (gamma-Al2O3), silicon oxide (SiO2), zirconium oxide (ZrO2), titanium oxide (TiO2), a silicon-aluminum molecular sieve and a phosphate-aluminum molecular sieve. A series of loaded type high-dispersion molybdenum sulfide catalysts are prepared with a high-temperature sulfuration method. The preparing method is simple in process, high in production efficiency, low in cost and especially suitable for preparing various loaded type transition metal sulfide catalysts, and the prepared catalysts are high in dispersion degree and have high catalytic hydrogenation activity.

Owner:TIANJIN UNIV

Preparation method of sulfurization type hydro-cracking catalyst

ActiveCN103769198AIncreased degree of vulcanizationImprove hydrogenation performanceMolecular sieve catalystsHydrocarbon oil crackingNickel saltTungstate

The invention discloses a preparation method of a sulfurization type hydro-cracking catalyst. The preparation method comprises the following steps: selecting a hydro-cracking catalyst carrier component, wherein the carrier component at least comprises an acidic cracking component; adding water into the carrier component powder, pulping so as to obtain slurry (c), then adding sulfo-molybdate and / or sulfo-tungstate slurry (a) and a nickel salt and / or cobalt salt solution (b) into the slurry (c), evenly stirring, filtering, washing, drying in the protection of inert gas, adding an adhesive, kneading, forming, and finally drying and burning in the protection of inert gas so as to obtain the sulfurization type hydro-cracking catalyst. The preparation method makes the active metal be evenly distributed on the carrier so as to generate more II type Ni(Co)Mo(W)S active phases with a higher activity; thus the catalyst has a high sulfurization degree and a high utilization rate of active metal, so that the hydrogenation performance of the catalyst is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-abrasion-resistance anti-aging tire rubber material

The invention discloses a high-abrasion-resistance anti-aging tire rubber material. The high-abrasion-resistance anti-aging tire rubber material is prepared from the following raw materials in parts by weight: 45-55 parts of epichlorohydrin rubber, 35-40 parts of ethylene propylene diene monomer, 20-25 parts of butadiene styrene rubber, 10-15 parts of chloroprene rubber, 1.5-2 parts of zircoaluminate coupling agent TL-5, 3-3.5 parts of 1,1,3,3-tetramethylperoxyphenoxybutyl acetate, 1.3-1.6 parts of 3,3-bis(tertiary pentylperoxy)ethyl butyrate, 2-4 parts of potassium carboxylacrylate, 4-7 parts of divinyl benzene, 10-12 parts of magnesium oxide, 25-30 parts of channel black, 20-30 parts of superfine hollow microspheres, 10-15 parts of lignin fiber, 25-30 parts of nano sepiolite powder, 20-25 parts of nano boron nitride, 30-40 parts of zinc borate, 2-3 parts of calcium stearate, 4-6 parts of barium stearate, 5-8 parts of phenyl petroleum sulfonate, 1-3 parts of antiager TMDQ and 2-4 parts of antiager NBC.

Owner:QIAOJIAN NEW ENERGY TECH SUZHOU

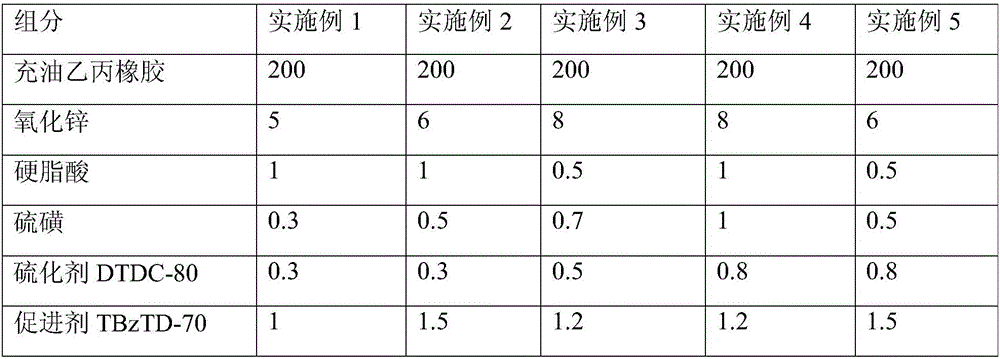

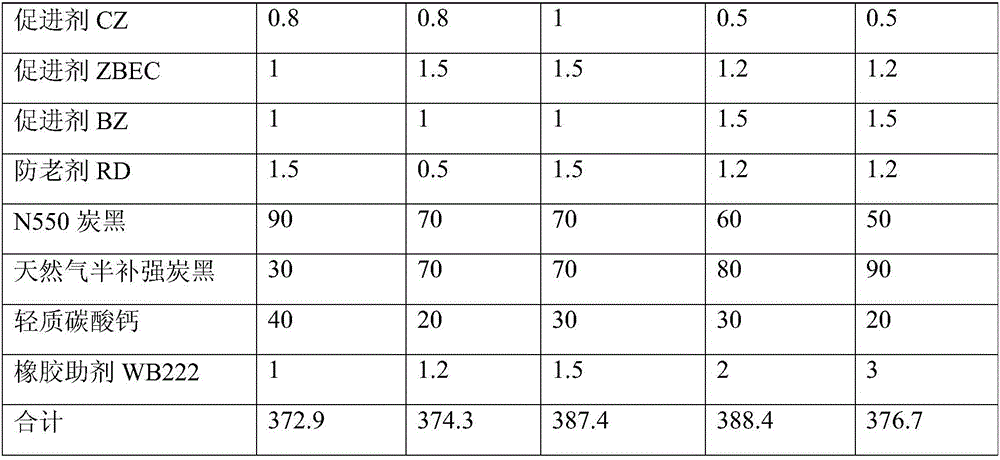

Environment-friendly anti-blooming ethylene propylene rubber compound

The invention discloses an environment-friendly anti-blooming ethylene propylene rubber compound.The ethylene propylene rubber compound is prepared from, by mass, 200 parts of oil-filling ethylene propylene diene monomer, 3-10 parts of zinc oxide, 0.5-3 parts of stearic acid, 0.2-1.5 parts of sulfur, 3-11.5 parts of accelerant, 0.3-2.5 parts of a vulcanizing agent, 0.5-3.5 parts of an anti-aging agent, 40-100 parts of N550 carbon black, 20-120 parts of natural gas semi-reinforcing carbon black, 20-50 parts of light calcium carbonate and 1-3 parts of flow promoter.The ethylene propylene rubber compound product cannot generate nitrosamine and other carcinogenic substances in the vulcanizing process, and the vulcanizing speed and the vulcanizing degree are increased on the premise that blooming does not occur.The blooming problem cannot occur in the parking process, appearance quality of products is excellent, and the ethylene propylene rubber compound has low hardness, environment friendliness, anti-blooming performance, high-temperature aging resistance and other excellent performance.

Owner:NANJING ORIENTLEADER TECH CO LTD

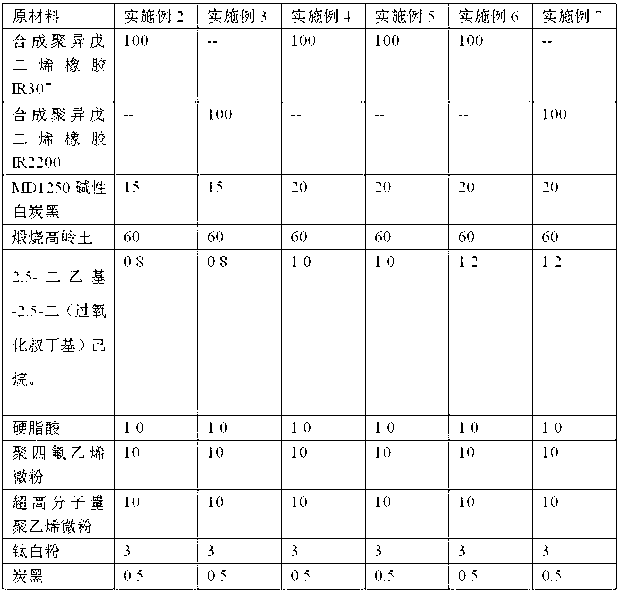

Rubber syringe needle protective cap for pre-encapsulation injection syringe and production method thereof

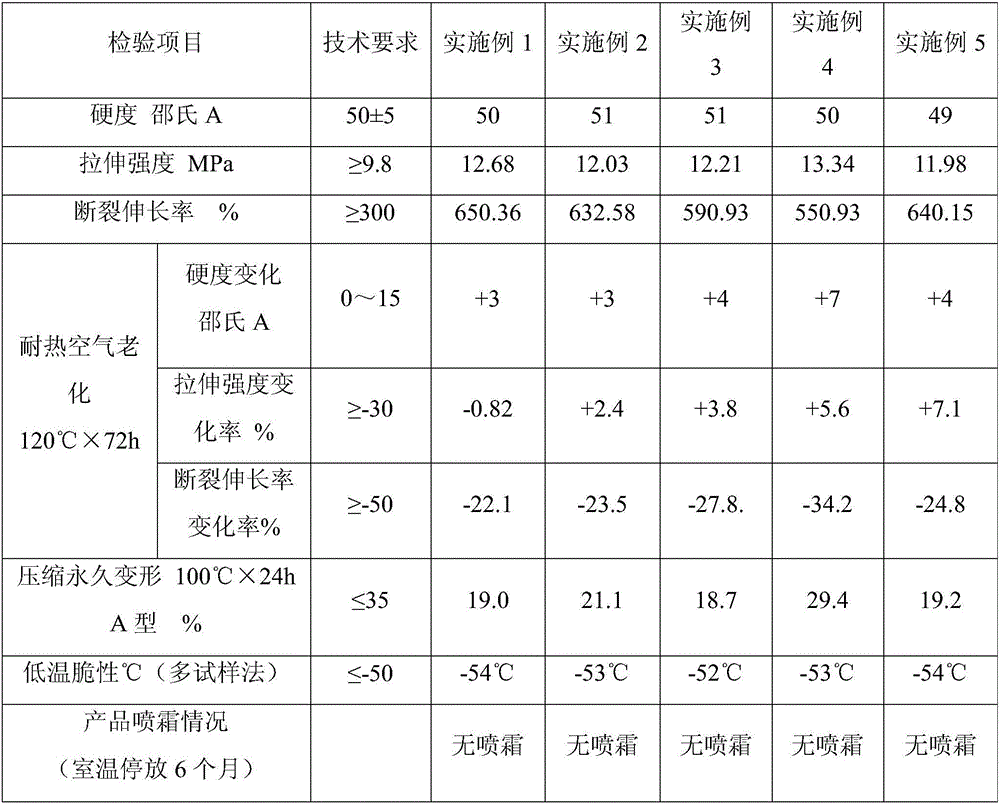

ActiveCN103232623AIncreased degree of vulcanizationSpeed up vulcanizationPolymer scienceSmell problems

The invention discloses a rubber syringe needle protective cap for a pre-encapsulation injection syringe. The protective cap is prepared from the following raw materials in parts by weight: 100 parts of synthesized polyisoprene rubber, 5-30 parts of alkaline white carbon black, 20-70 parts of calcined kaolin, 0.3-1.2 parts of peroxide, 0.5-1.0 part of stearic acid, 5-20 parts of polytetrafluoroethylene micro powder, 5-20 parts of ultra-high molecular weight polyethylene micro powder, 1-5 parts of titanium dioxide and 1-3 parts of carbon black. The rubber syringe needle protective cap has the obvious characteristics that a clean and simple peroxide sulfuration system is adopted, and a conventional complicated sulfur and zinc oxide promotion system is avoided. Special alkaline fillers are adopted, the sulfuration degree and speed of rubber are improved, and a smell problem caused by adopting the peroxide to sulfurate the polyisoprene rubber is reduced. The polytetrafluoroethylene micro powder and the ultra-high molecular weight polyethylene micro powder with good inertness and dispersibility are added into a formula, the lubricity and chemical inertness of the rubber are improved, and the viscous resistance of a rubber syringe needle protective cap product is improved.

Owner:郑州翱翔医药科技股份有限公司

Preparation method of rubber active agent

InactiveCN102250496AReduce resource usageHazard reductionPigment treatment with organosilicon compoundsVulcanizationActive agent

The invention discloses a preparation method of a rubber active agent. The method mainly comprises the steps of: burning and refining dried rice hulls, mixing the rice hulls with calcinated kaolin and a silane coupling agent proportionally, and putting the mixture into a high temperature mixing machine for a surface bioactive treatment, thus obtaining a product. According to the invention, the use of zinc oxide in butyl tire tube production is substituted, the use of petrochemical resources can be reduced and the harm to the environment is also reduced, thus achieving energy conservation and environmental protection. Therefore, the rubber active agent of the invention is an environmental friendly novel material, which both speeds up vulcanization and improves the vulcanization degree, thus serving as a reinforcing agent and a coloring agent.

Owner:ANHUI YANGLUN CHEM

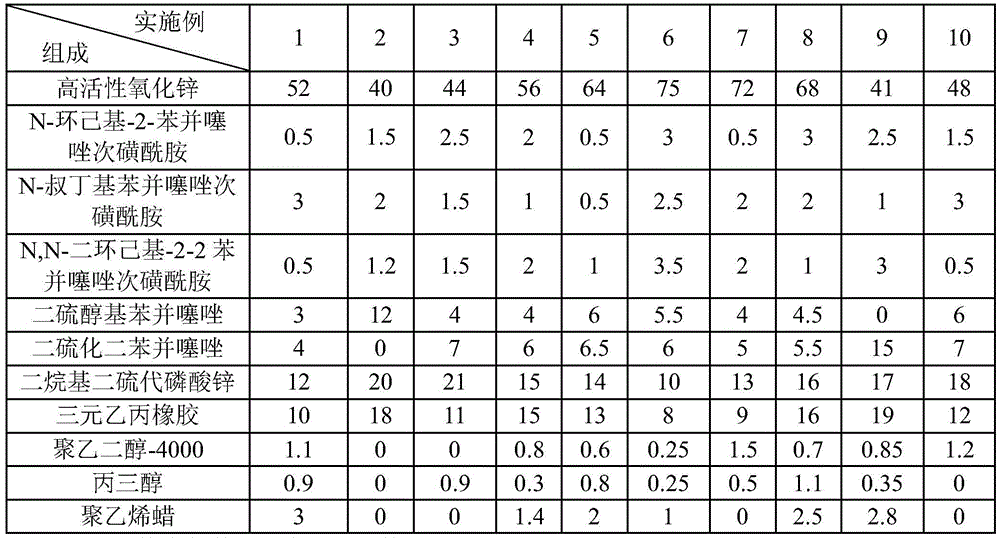

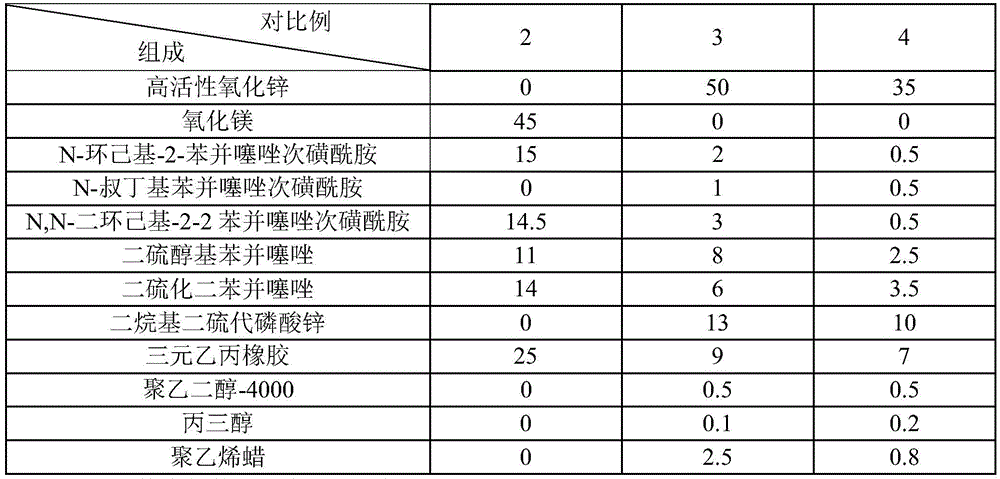

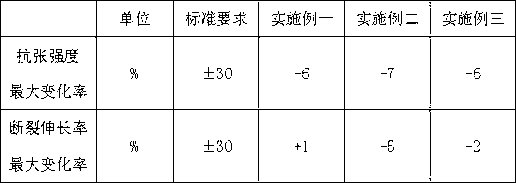

Rubber comprehensive accelerator and method for preparing same

The invention discloses a rubber comprehensive accelerator and a method for preparing the same.The rubber comprehensive accelerator mainly comprises, by weight, 40-75 parts of high-activity zinc oxide, 2-9 parts of after-effectiveness sulfenamide accelerators, 7-15 parts of thiazole accelerators, 10-21 parts of ultrahigh-speed accelerators and 8-19 parts of macromolecular carriers.The rubber comprehensive accelerator and the method have the advantages that different types of additives can be sufficiently mixed with one another by the aid of a step-by-step adding process, accordingly, the rubber comprehensive accelerator is excellent in aging resistance and yellowing resistance, and mechanical properties of rubber products further can be improved.

Owner:YONGJIA WEICHENG RUBBER IND & TRADE CO LTD

Wear-resisting and oil-resisting oil pipe rubber material

The invention discloses a wear-resisting and oil-resisting oil pipe rubber material. The wear-resisting and oil-resisting oil pipe rubber material is prepared from the following raw materials in parts by weight: 40-50 parts of epichlorohydrin rubber, 25-30 parts of chlorinated natural rubber, 15-20 parts of butadiene styrene rubber, 10-15 parts of carboxylic acrylonitrile butadiene rubber, 2-5 parts of 1,1-di(t-butylperoxy)-3,3,5-trimethylsiloxane, 1-1.5 parts of bis-2,4-dichlorobenzoyl peroxide, 0.3-0.6 part of 2,5-dimethyl-2,5-di(tert-butyl peroxy)hexane, 4-6 parts of sulfur powder, 2-4 parts of triethanolamine, 5-7 parts of zinc oxide, 25-30 parts of channel black, 20-30 parts of superfine hollow microspheres, 15-20 parts of fumed silica, 25-30 parts of nano calcined kaolinite, 20-25 parts of nano-titanium nitride, 30-40 parts of magnesium hydroxide, 2-3 parts of barium stearate, 4-6 parts of trioctyl trimellitate, 1-3 parts of antiager MB and 2-4 parts of antiager NBC.

Owner:QIAOJIAN NEW ENERGY TECH SUZHOU

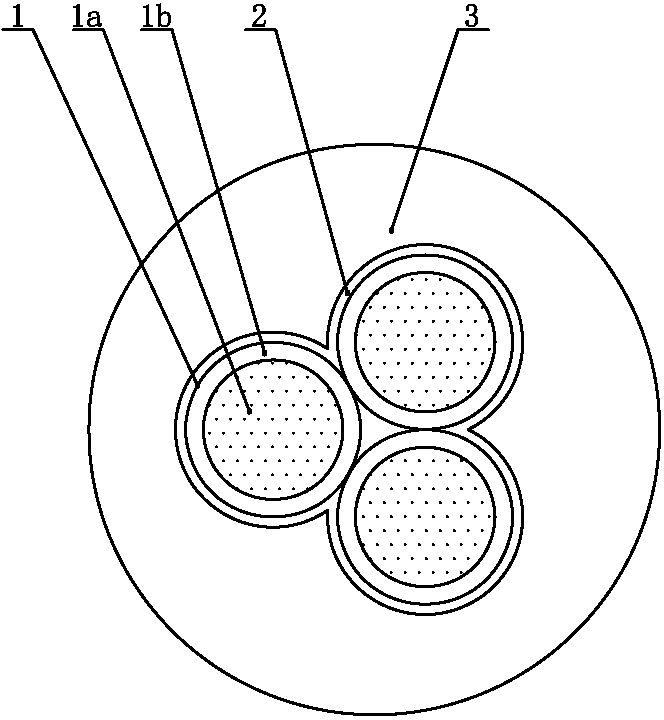

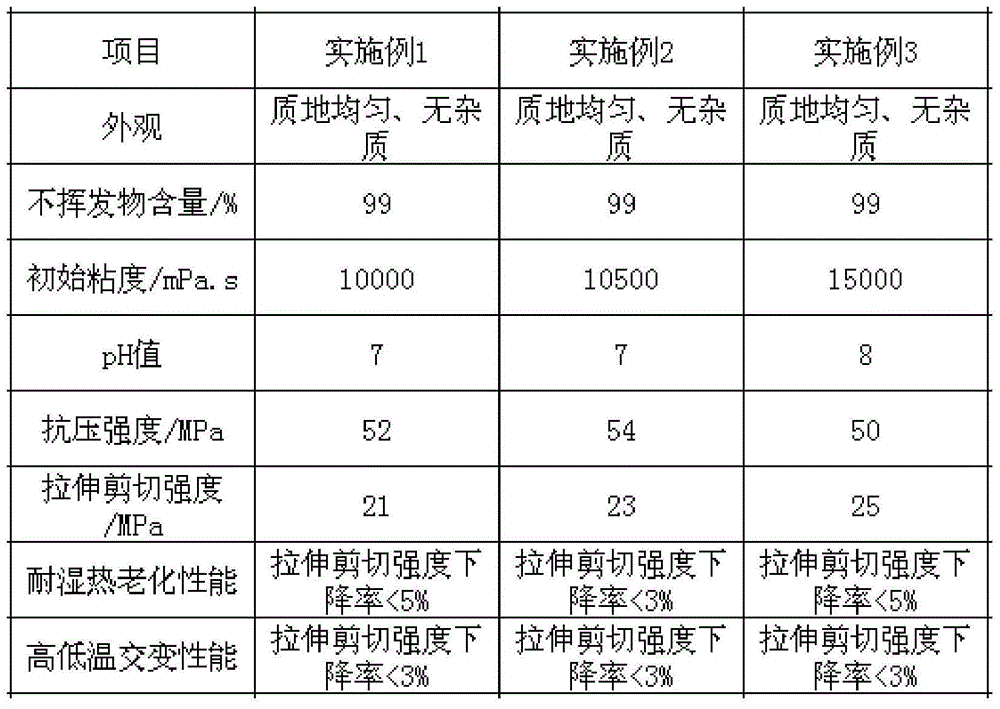

Salt corrosion resistant and twisting resistant power cable for ocean wind power and manufacturing method of power cable

ActiveCN103227008AReduce tensionEliminate voidsPower cablesInsulating conductors/cablesCopper conductorElectricity

The invention relates to a salt corrosion resistant and twisting resistant power cable for ocean wind power and a manufacturing method of the power cable. A stranded copper conductor is uniformly wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form a power cable insulated core; a plurality of power cable insulated cores are mutually stranded to form a power cable core; the power cable core is wrapped in a low-strength non-woven fabric longitudinal wrap on the periphery; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The power cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the power cable insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the power cable insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

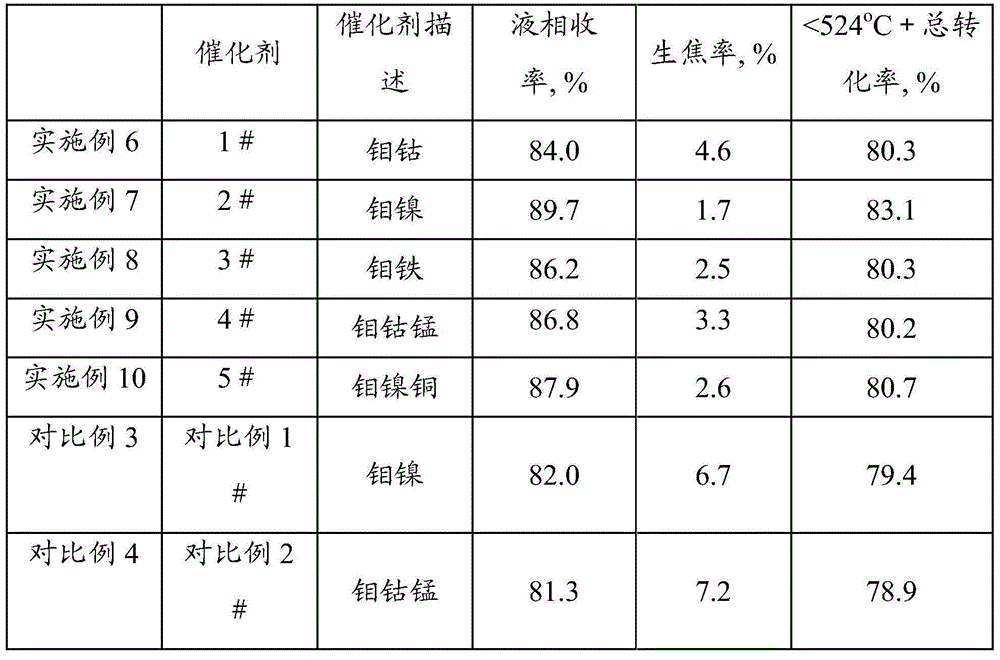

Preparation method of hydrogenation catalyst for slurry bed of heavy oil as well as catalyst and application thereof

InactiveCN106311341AThe initial particle size of precipitation is smallEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsTreatment with moving solid particlesManganeseFuel oil

The invention provides a preparation method of a hydrogenation catalyst for a slurry bed of heavy oil as well as the catalyst and an application thereof. The preparation method comprises the following steps: a molybdenum-containing compound and at least one soluble salt of a metal element which is selected from nickel, cobalt, iron, manganese and copper are dissolved in an aqueous solution; organic acid is added in order to generate sol; a sulfuration reaction is directly carried out in order to obtain ultrafine solid powder in sulfurized state; emulsification and dispersion of the obtained ultrafine solid powder in sulfurized state and distillate oil are carried out, in order to obtain the hydrogenation catalyst for a slurry bed of heavy oil. The hydrogenation catalyst for the slurry bed of heavy oil is applied to a hydrogenation process of a heavy oil raw material of the slurry bed or a suspended bed, the catalyst has good dispersion performance and hydrocracking performance in heavy oil, and coking formation rate can be effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of sulfurization type hydro-treatment catalyst

ActiveCN103769168AIncreased degree of vulcanizationImprove utilization efficiencyPhysical/chemical process catalystsRefining to eliminate hetero atomsAmmonium sulphideActive phase

The invention provides a preparation method of a sulfurization type hydro-treatment catalyst. The preparation method comprises the following steps: adding water into carrier powder, pulping so as to obtain slurry (d), adding an ammonium molybdate and / or ammonium tungstate solution (a), an ammonium sulphide solution (b), and a nickel salt and / or cobalt salt solution (c) into the slurry (d) to carry out reactions, adding a surfactant at the same time, filtering, washing, and drying the reaction product in the protection of inert gas, adding an adhesive, kneading, extruding into strips, forming, drying in the protection of inert gas, and finally burning so as to obtain the sulfurization type hydro-treatment catalyst. The preparation method makes the active metal be evenly distributed on the carrier so as to generate more II type Ni(Co)Mo(W)S active phases with a higher activity; thus the catalyst has a high sulfurization degree and a high utilization rate of active metal, so that the hydrogenation performance of the catalyst is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

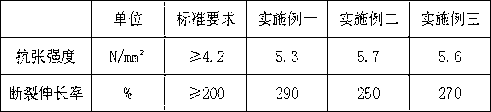

Modified bamboo charcoal fiber-rubber composite sole material, preparation method and application

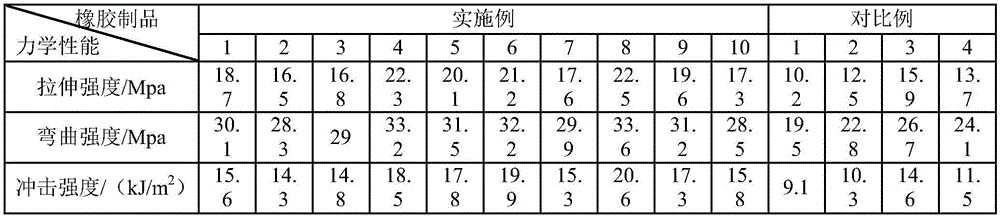

ActiveCN107417998AImprove toughness and strengthHigh tensile strengthSolesFibre typesButadiene-styrene rubberOxide

The invention discloses a modified bamboo charcoal fiber and rubber composite material, a preparation method therefor and an application of the modified bamboo charcoal fiber and rubber composite material. The composite material is prepared from the following ingredients in parts by weight: 100 parts of natural rubber, cis-butadiene rubber and styrene-butadiene rubber blended rubber, 15-35 parts of modified bamboo charcoal fibers, 1.2-3.3 parts of sulfur, 2.5-4 parts of zinc oxide, 0.9-1.3 parts of stearic acid and 1.2-2 parts of accelerant TMTD. The preparation method comprises the steps of using the natural rubber, cis-butadiene rubber and styrene-butadiene rubber blended rubber as a raw material, carrying out milling and plastifying on the modified bamboo charcoal fibers, processing aids and the blended rubber in mixing and milling procedures of the raw material, and carrying out procedures such as vulcanization, thereby preparing a modified bamboo charcoal fiber containing rubber composite material and products. The composite material and the products thereof, prepared by the method, can serve as a shoe sole material and can meet the requirements of novel shoe soles on light weight and low cost.

Owner:贝克兰(厦门)新材料有限公司

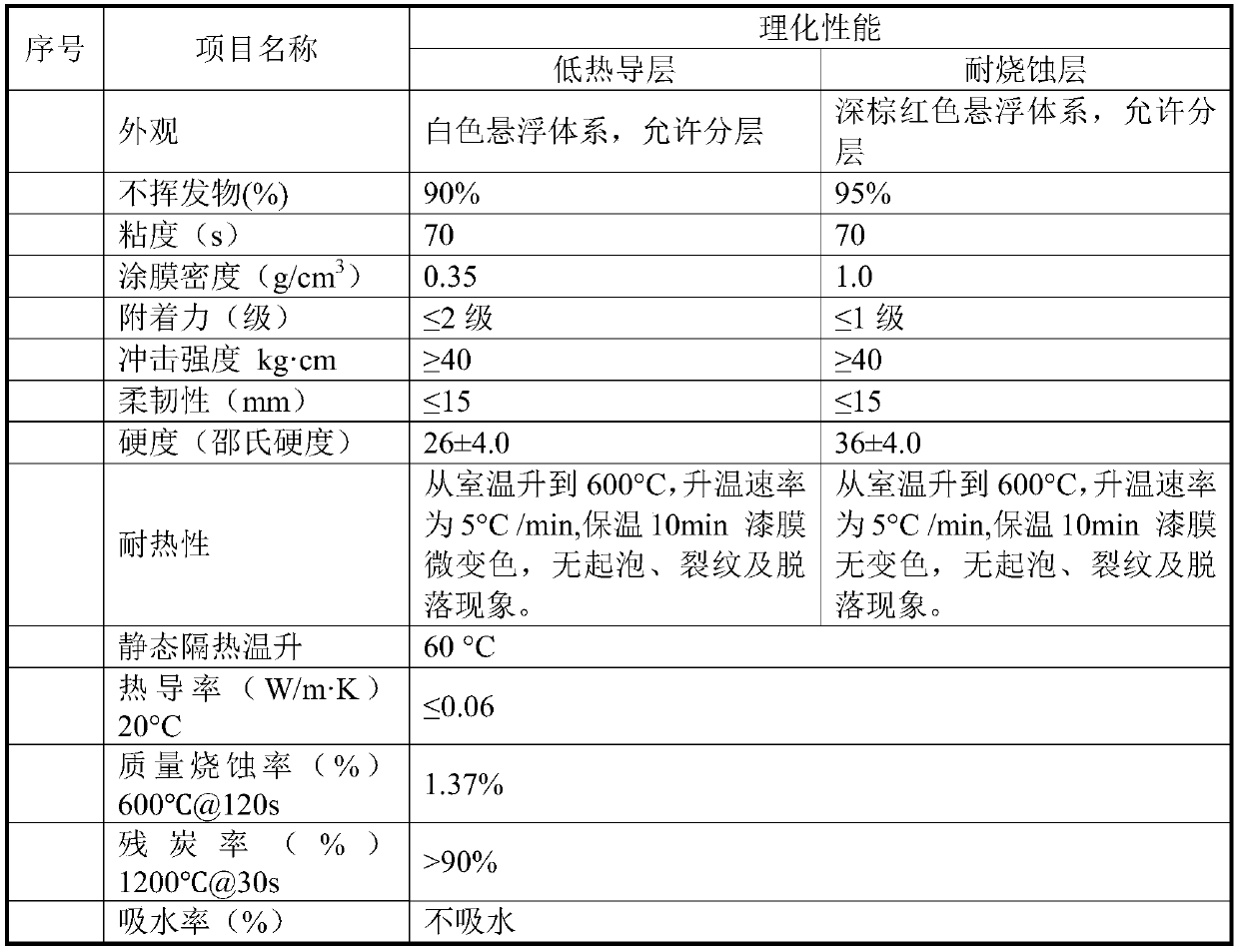

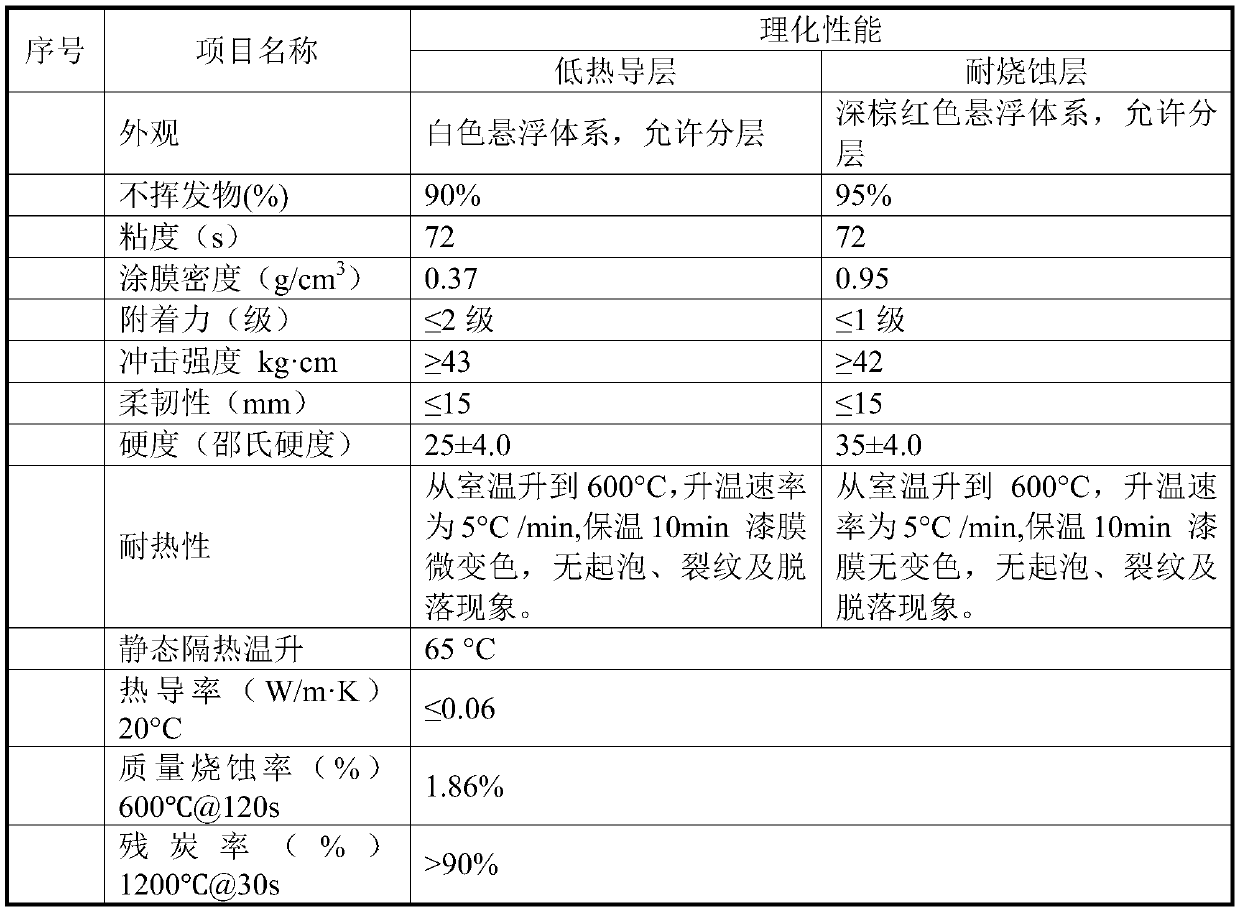

Ablation-resisting light silicone rubber thermal insulation coating

The invention relates to an ablation-resisting light silicone rubber thermal insulation coating. The ablation-resisting light silicone rubber thermal insulation coating comprises an inner low-thermal-conductivity layer and an outer ablation-resisting layer at a thickness ratio of 2-10:1-5, wherein the ablation-resisting layer is prepared from three components and releases heat via mass loss; the low-thermal-conductivity layer is prepared from three components and reduces longitudinal heat conduction through ultra-low thermal conductivity. Compared with the prior art, the ablation-resisting light silicone rubber thermal insulation coating has the advantages of being low in mass ablating rate, high in heat resistance and long in service life at high temperatures and can effectively resist impact of heat flow of 500 kW / m2 and above, reduce temperature increase of base plates and prevent base materials from losing efficacy due to high-temperature erosion.

Owner:SHANGHAI JIAO TONG UNIV +1

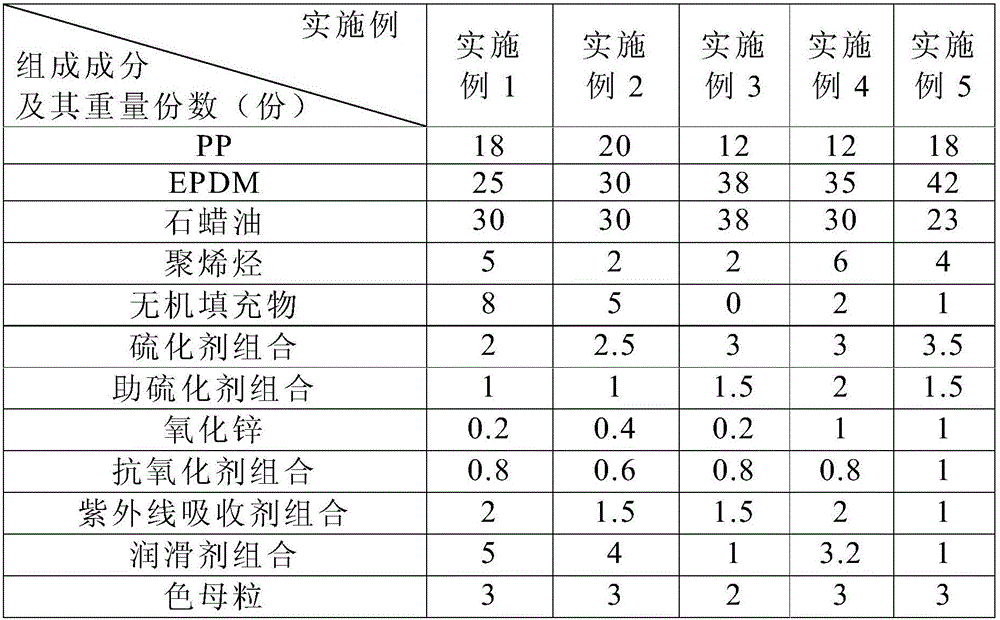

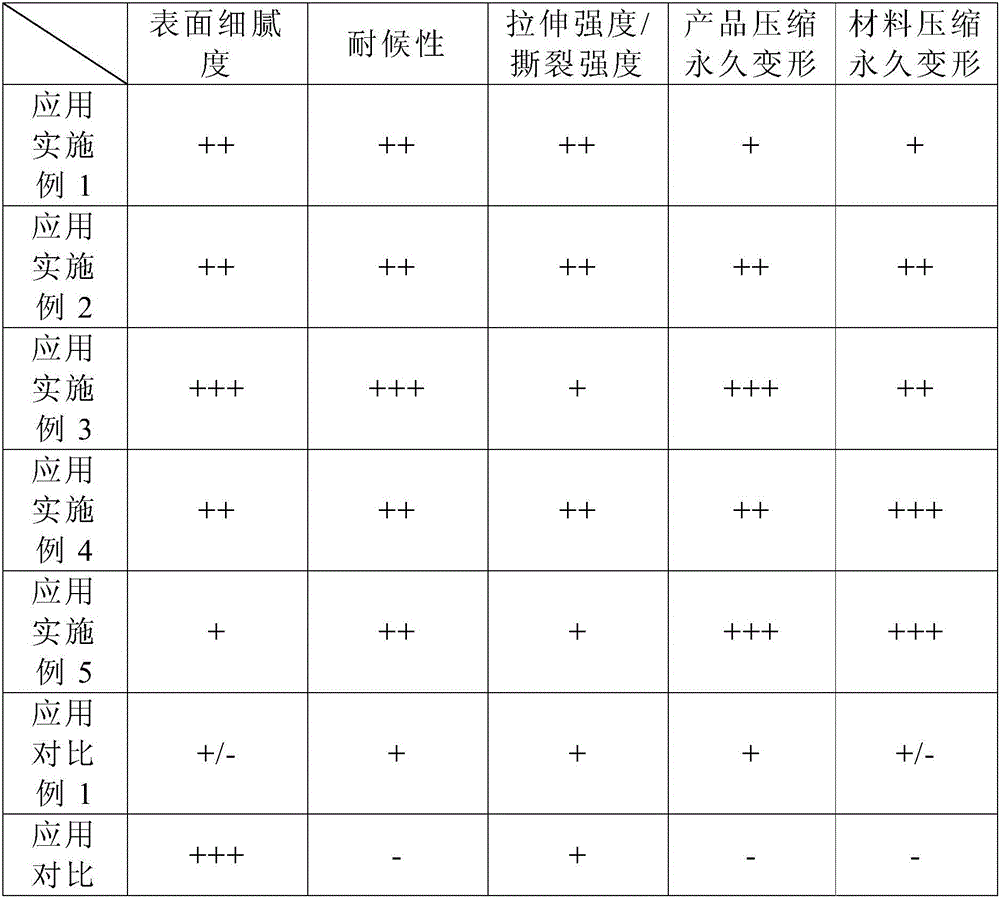

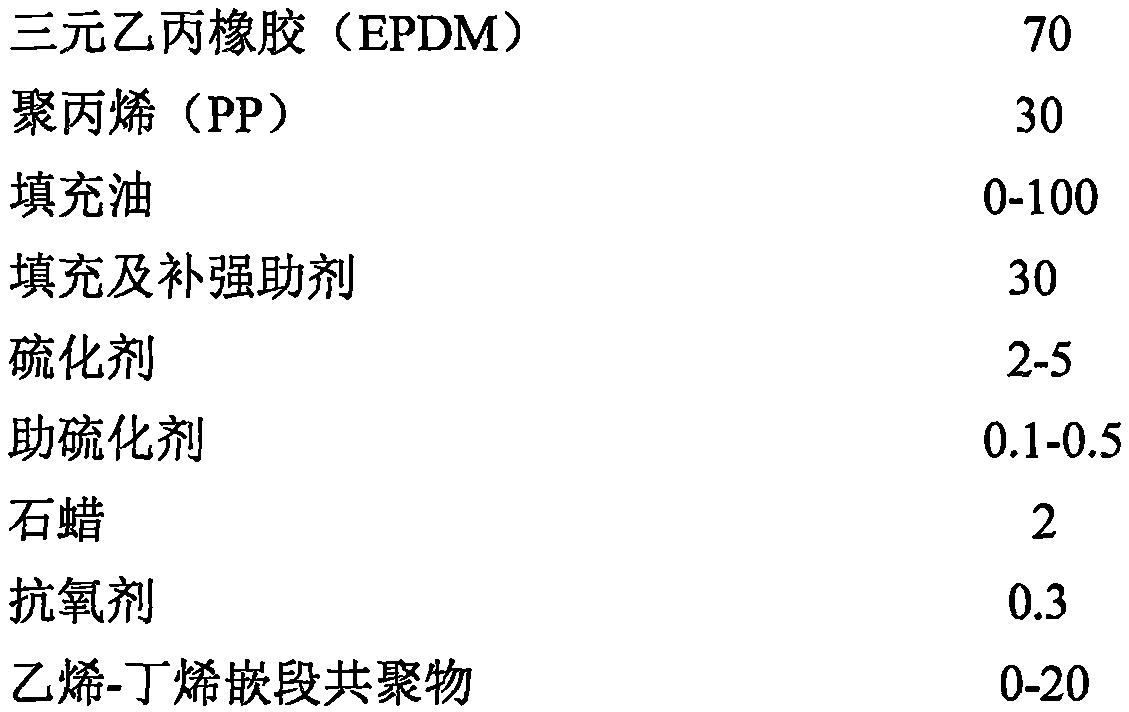

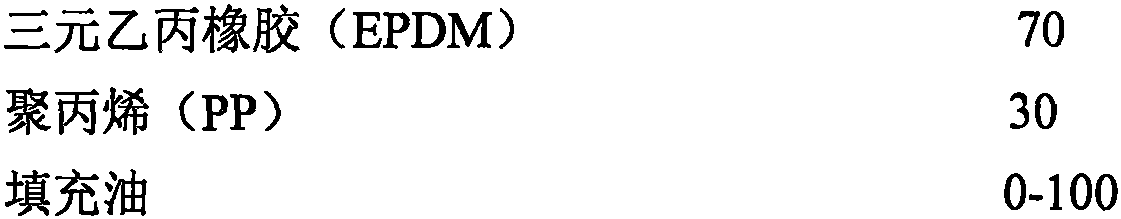

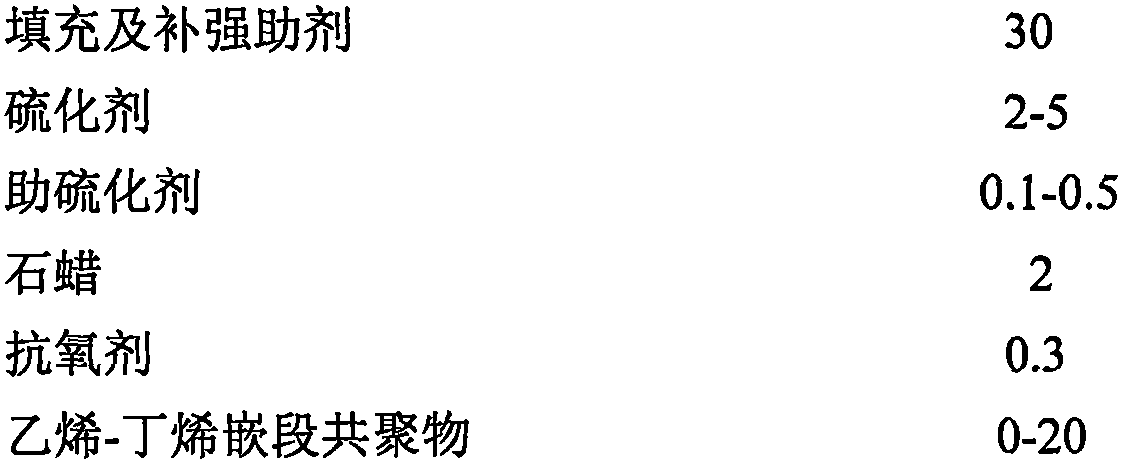

TPV material and preparation method and application thereof

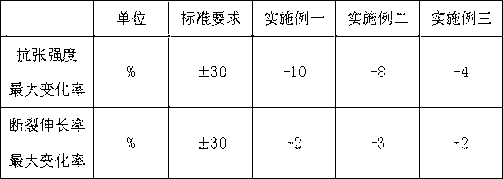

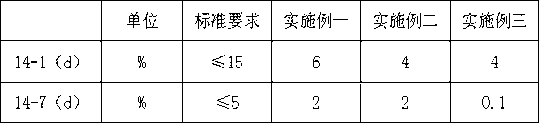

The invention relates to a TPV material and a preparation method and application thereof. The TPV material is mainly prepared from, by weight, 8-30 parts of PP, 15-50 parts of EPDM, 15-50 parts of paraffin oil, 1-10 parts of polyolefin, 0-12 parts of inorganic filler, 0.5-6 parts of vulcanizing agent composition, 0.5-4 parts of assistant vulcanizing agent composition, 0.1-4 parts of zinc oxide, 0.5-2 parts of antioxidant composition, 0.5-4 parts of ultraviolet light absorber composition, 0.5-8 parts of lubricant composition and 2-5 parts of color masterbatch. The TPV material is prepared through material mixing and vulcanizing. The prepared TPV material has higher surface fine and smooth degree, tensile strength and tear strength, better compression permanent deformation and more stable heat aging and the aging. The TPV material is used for the preparation of automobile glass water-draining strips, can meet the appearance demand for high surface fine and smooth degree of an auto main engine plants, as well as the compression permanent deformation and physical property requirements for light and heat aging.

Owner:NINGBO TAIYONG AUTOMOTIVE PARTS

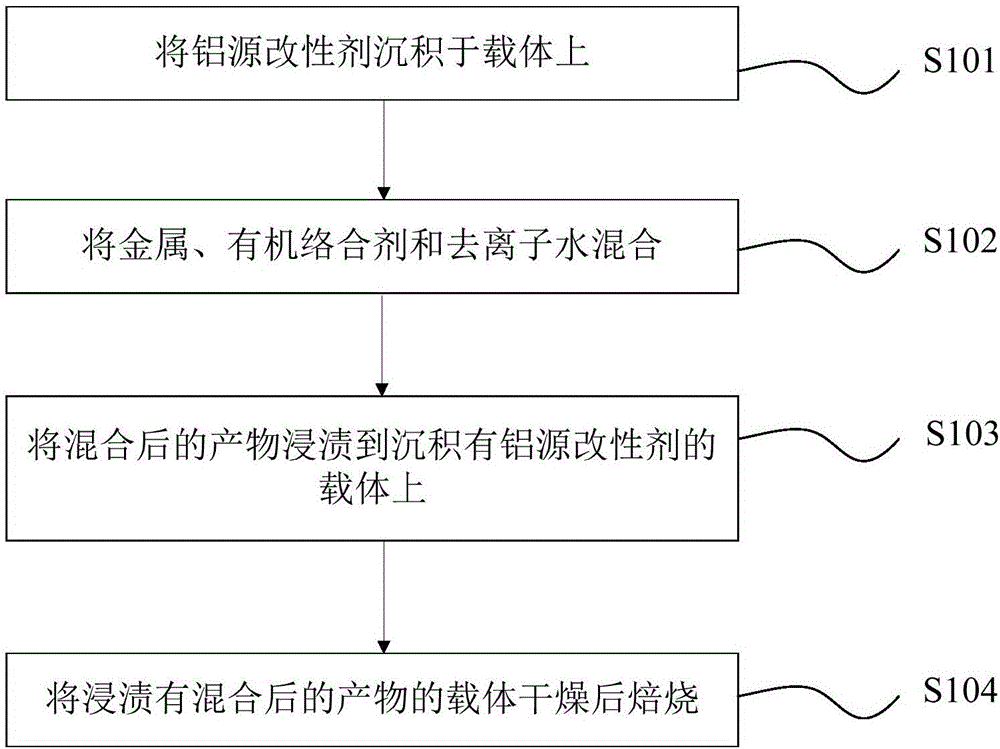

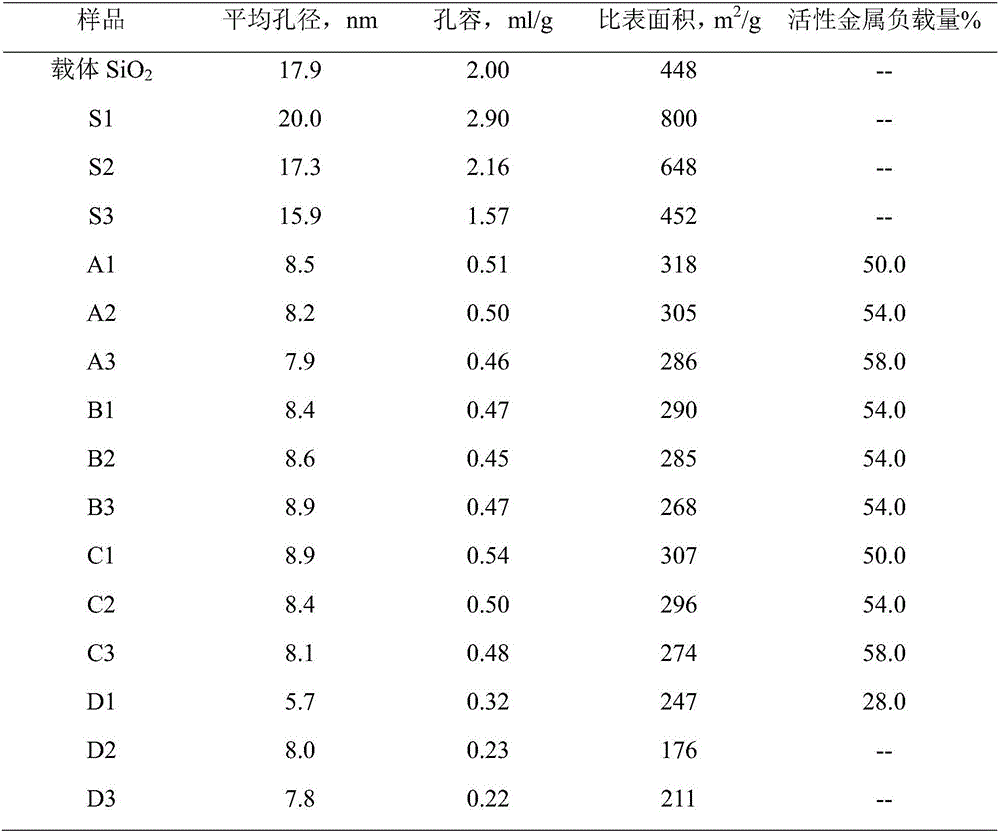

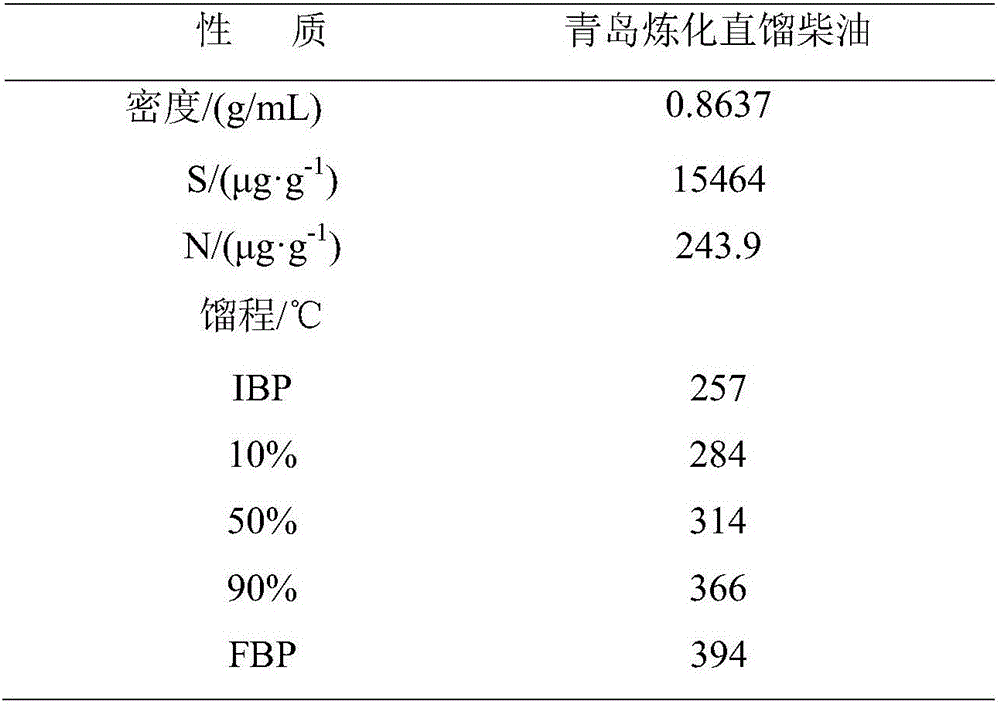

Method for preparing superhigh metal load capacity hydrogenation catalyst

ActiveCN106475110AHigh activitySimple preparation processCatalyst carriersHeterogenous catalyst chemical elementsChlorideAluminium isopropoxide

The invention relates to a method for preparing a superhigh metal load capacity hydrogenation catalyst. The method comprises the following steps: depositing an aluminum source modifier on a carrier; metal, an organic complexing agent and deionized water are mixed; the mixed product is dipped on a carrier deposited with the aluminum source modifier; the carrier dipped with the mixed product is dried and roasted; wherein, the main metal components are Mo and W of VIB family, the auxiliary agent components are Co and / or Ni of VIII family; the aluminum source modifier is one or combination of aluminum isopropoxide, aluminum chloride and aluminum nitrate; the pore volume of the carrier deposited with the aluminum source modifier is 1.5-3.0 ml / g, the specific surface area is 400-800 m<2> / g, and the aperture proportion of the aperture with 15-20 nm is greater than 50%. According to the preparation method of the invention, catalyst activity is obviously increased by increasing the metal load capacity, the catalyst has a good pore structure and a large specific surface area; preparation flow of the catalyst is simplified, and the preparation cost of the hydrogenation catalyst with high metal content is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Silica gel gasket with high heat conductivity and method for preparing silica gel gasket

InactiveCN108727826ASpread evenlyGood thermal weight loss retentionHeat-exchange elementsPolymer scienceBenzoyl peroxide

The invention discloses a silica gel gasket with high heat conductivity and a method for preparing the silica gel gasket. The silica gel gasket with the high heat conductivity comprises, by weight, 5-10 parts of methyl vinyl silicone rubber, 5-15 parts of white carbon black, 30-50 parts of silicon carbide, 80-600 parts of boron nitride, 10-30 parts of hydroxyl silicone oil, 5-15 parts of chloroplatinic acid, 10-20 parts of modified graphite, 3-8 parts of benzoyl peroxide and 2-5 parts of bis-di-penta-vulcanizing auxiliaries. The method for preparing the silica gel gasket with the high heat conductivity includes steps of (1), uniformly alternately adding heat conduction fillers, reinforcement fillers, coupling agents and the like into the methyl vinyl silicone rubber and uniformly mixing the methyl vinyl silicone rubber, the heat conduction fillers, the reinforcement fillers, the coupling agents and the like with one another to obtain first mixtures, gradually adding a vulcanizing agent(the benzoyl peroxide) and vulcanizing auxiliaries into the first mixtures, and mixing the vulcanizing agent, the vulcanizing auxiliaries and the first mixtures with one another on a mixing mill forapproximately 2 h to uniformly disperse various component fillers in methyl vinyl silicone rubber matrixes; (2), allowing mixed silicone rubber materials to stand still for 24 h to promote excellent effects of the heat conduction fillers and the reinforcement fillers.

Owner:苏州速传导热电子材料科技有限公司

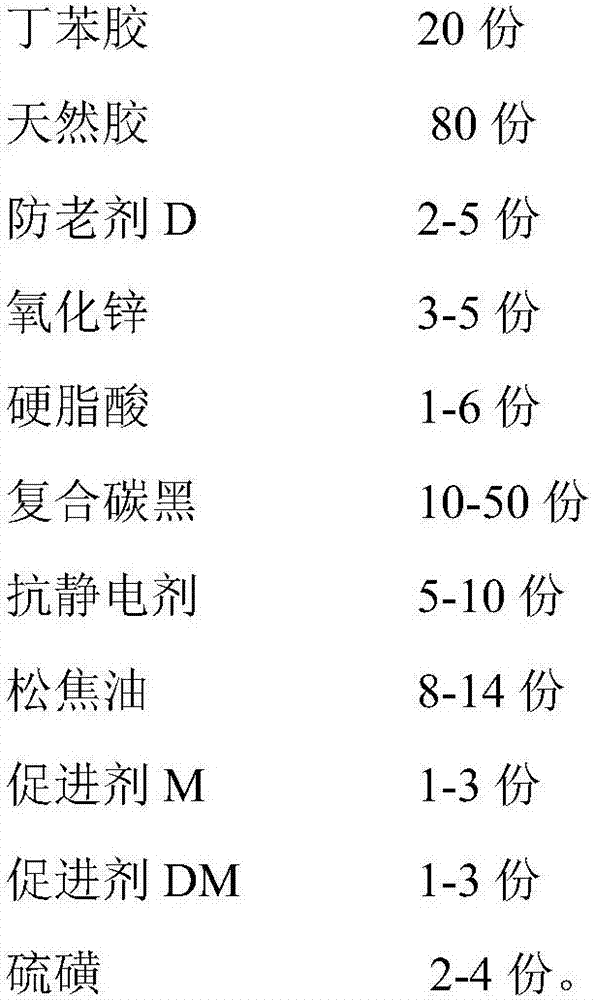

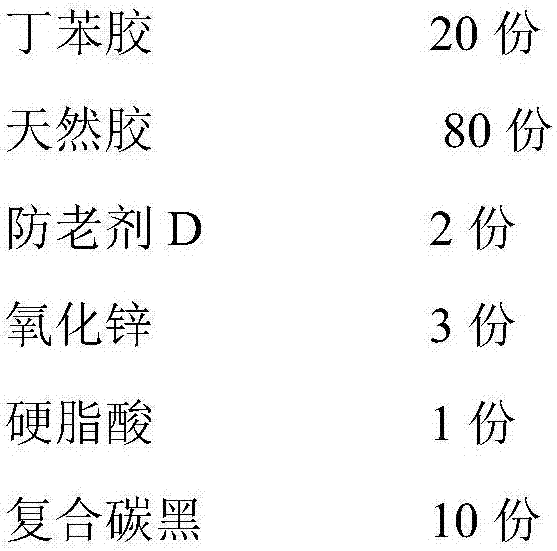

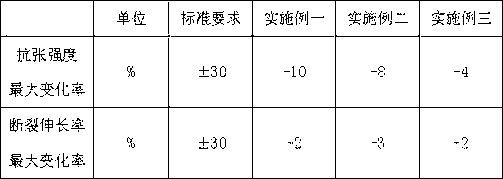

Anti-static rubber and preparation method thereof

InactiveCN107417991AEasy to processImprove wear resistanceBuilding insulationsAntistatic agentHardness

The invention discloses an anti-static rubber and a preparation method thereof and belongs to the field of rubber manufacturing. The anti-static rubber and the preparation method thereof aim at solving the problems of anti-static deficiency, poor physical performance and low heat generation rate in the prior art. The anti-static rubber is a compound conductive carbon black composition combined with anti-static agent, thereby effectively guaranteeing anti-static effects, improving wear resistance; compounded carbon black is low in heat value during operation and can ensure hardness and ductility of the anti-static rubber. By means of a two-section plastifying manner and through synergistic effects of the compounded carbon black and the anti-static agent, the anti-static rubber achieves good anti-static effects, excellent physical performance, good hardness and tensile strength, low heat value and simple production processes.

Owner:MAANSHAN TIANXIN ROLL IND

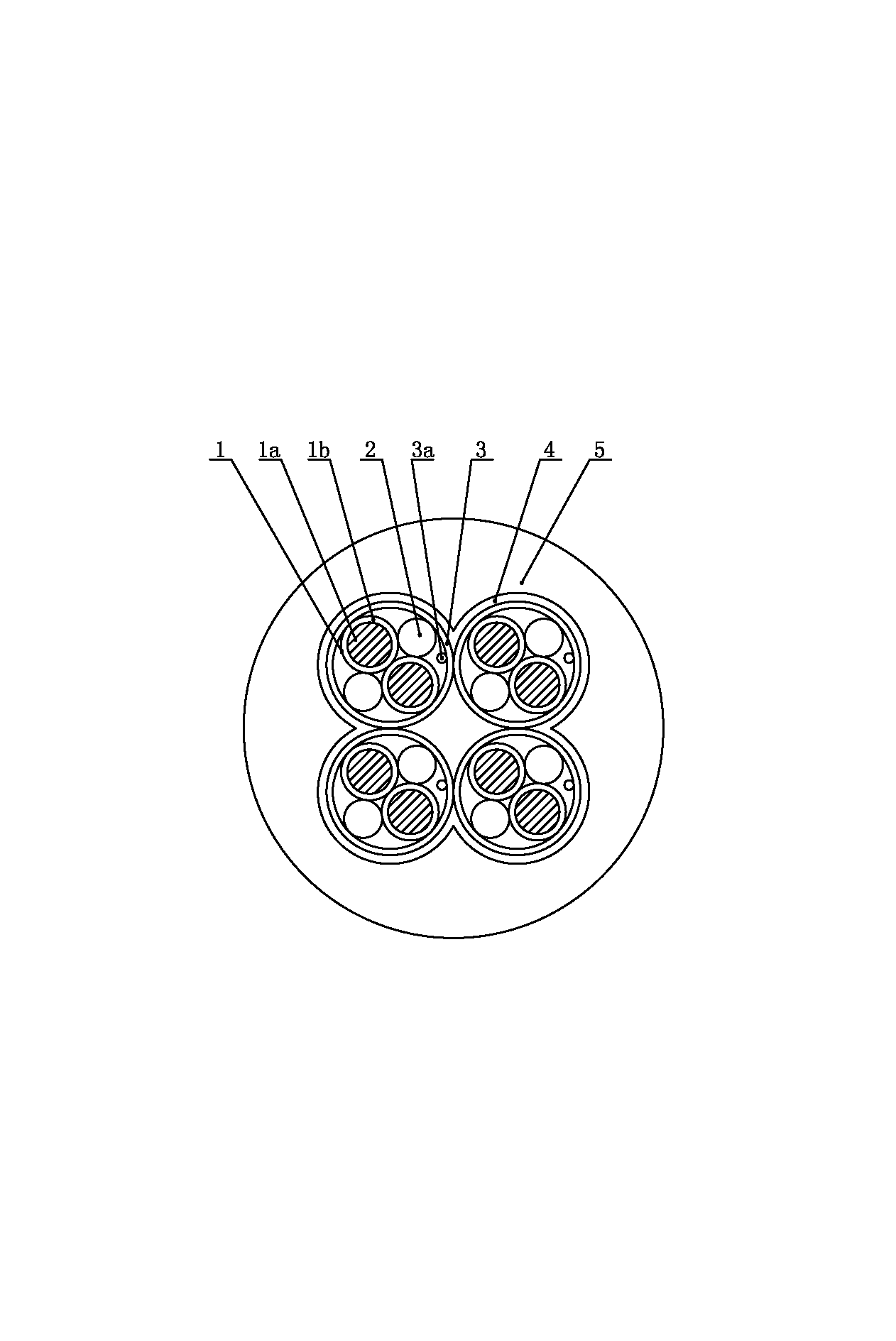

Salt corrosion and torsion resisting type shielding telecommunication cable used for ocean wind power and manufacturing method thereof

ActiveCN103187127AEliminate voidsExcellent impregnationRubber insulatorsInsulating conductors/cablesCopper conductorFiber

The invention relates to a salt corrosion and torsion resisting type shielding telecommunication cable used for ocean wind power and a manufacturing method thereof. A salt corrosion and torsion resisting type rubber insulating layer is uniformly extruded to wrap the peripheries of stranded copper conductors in order to form insulating wires, the insulating wires are stranded in pairs to form a stranded wire pair, the gap of the stranded wire pair is filled with a flame-retardant non-hygroscopic fiber filling core, the periphery of each group of stranded wire pair is wound with a copper foil polyester compounding belt shielding layer to form a stranded group, multiple stranded groups are mutually stranded to form a cable core, and the periphery of the cable core is wrapped with low strength non-woven fabrics, and is extruded with a protective sleeve. According to the salt corrosion and torsion resisting type shielding telecommunication cable, a longitudinal low strength non-woven fabric wrapping layer is adopted, and is completely matched with the insulating wire core in shape, so that the gap between the longitudinal low strength non-woven fabric wrapping layer and the insulating wire core is eliminated, a flame can be favorably prevented from being continuously transmitted to the inside under the combustion condition, and the humidity steeping resistance is improved. Meanwhile, the longitudinal low strength non-woven fabric wrapping layer can ensure that the protective sleeve does not adhere to the insulating wire core, and facilitates the stripping of the protective sleeve in the construction process without damages on the insulating wire core.

Owner:浙江华威设备制造有限公司

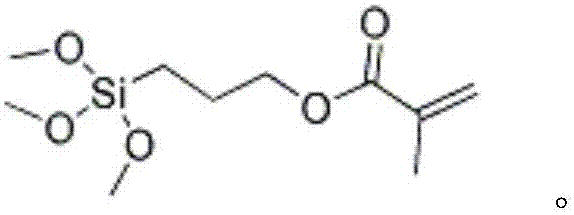

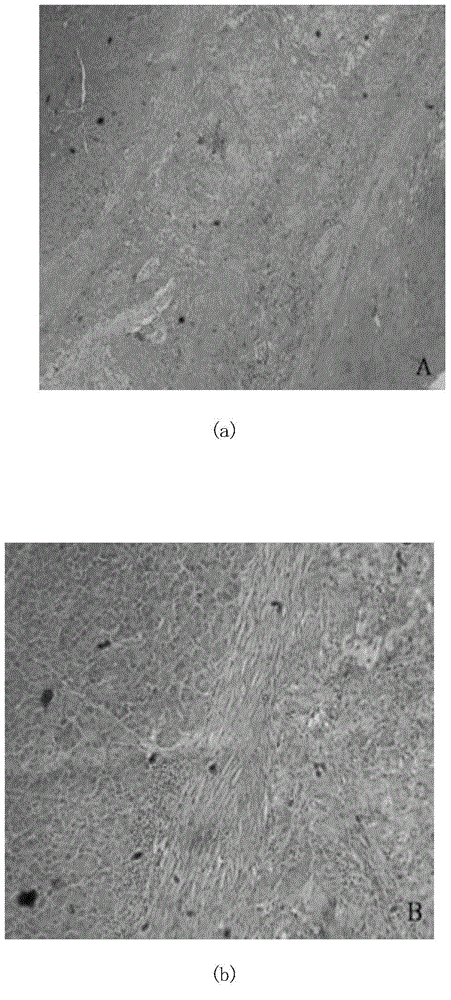

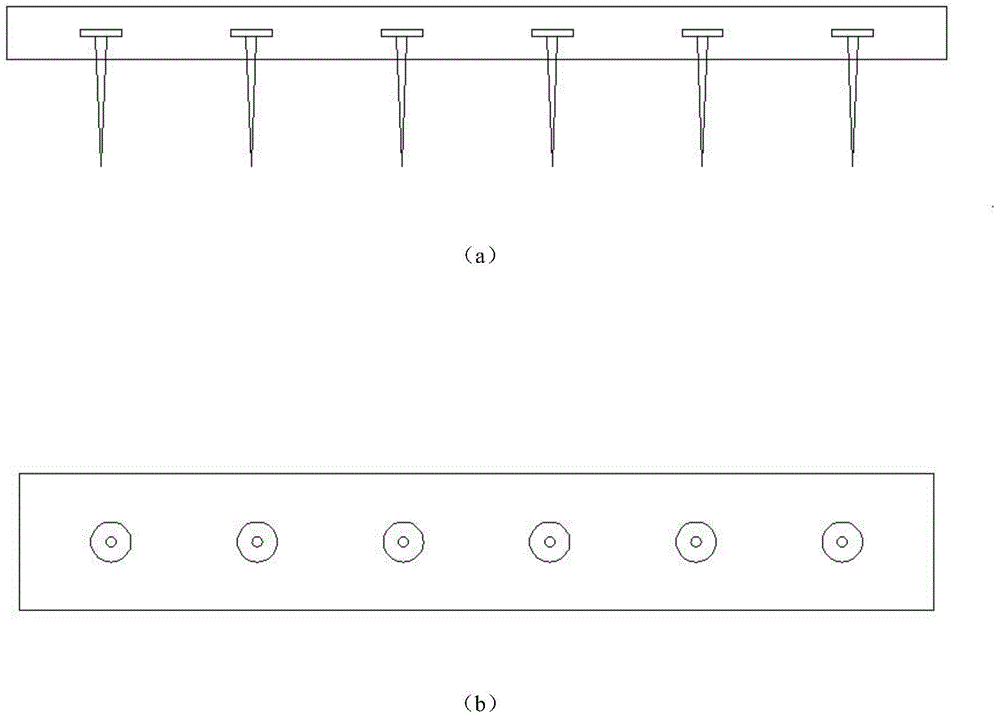

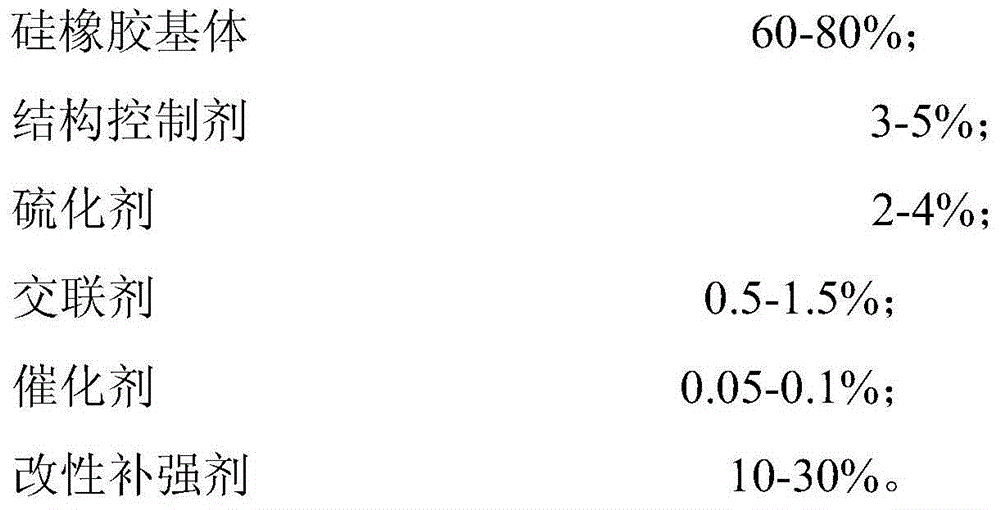

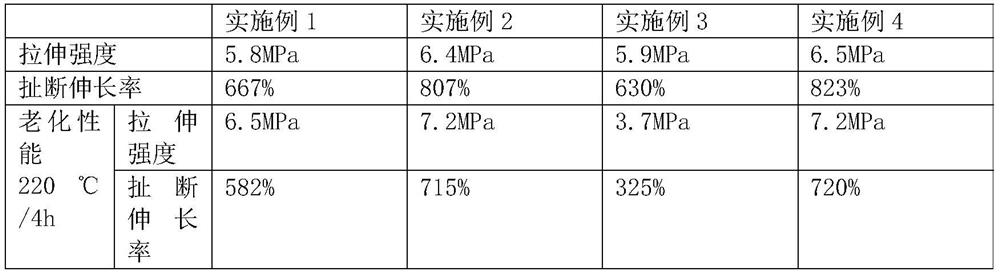

Medical organosilicone material for pancreas and intestine anastomosis instrument and preparation method thereof

The invention discloses a medical organosilicone material for a pancreas and intestine anastomosis instrument and a preparation method thereof. The medical organosilicone material is prepared from 60-80% of a silicone rubber matrix, 3-5% of a structure controlling agent, 2-4% of a vulcanizing agent, 0.5-1.5% of a crosslinking agent, 0.05-0.1% of a catalyst and 10-30% of a reinforcing agent. The preparation method of the medical organosilicone material comprises the following steps: (1) preparing rubber master batch; (2) mixing; (3) standing a rubber compound; (4) vulcanizing in two stages; and (5) increasing temperature gradually, and treating to obtain the medical organosilicone elastomer material. The invention further discloses the pancreas and intestine anastomosis instrument produced from the medical organosilicone elastomer material. The pancreas and intestine anastomosis instrument is in a strip shape, and titanium screws are uniformly distributed on the pancreas and intestine anastomosis instrument. The medical organosilicone elastomer material has the characteristics of high ductility, high tear strength, high flexibility and excellent medium resistance, is non-toxic physiologically and can be widely applied to the medical field.

Owner:XIAN UNIV OF SCI & TECH

Roasting-free hydrogenation catalyst and its preparation method and application

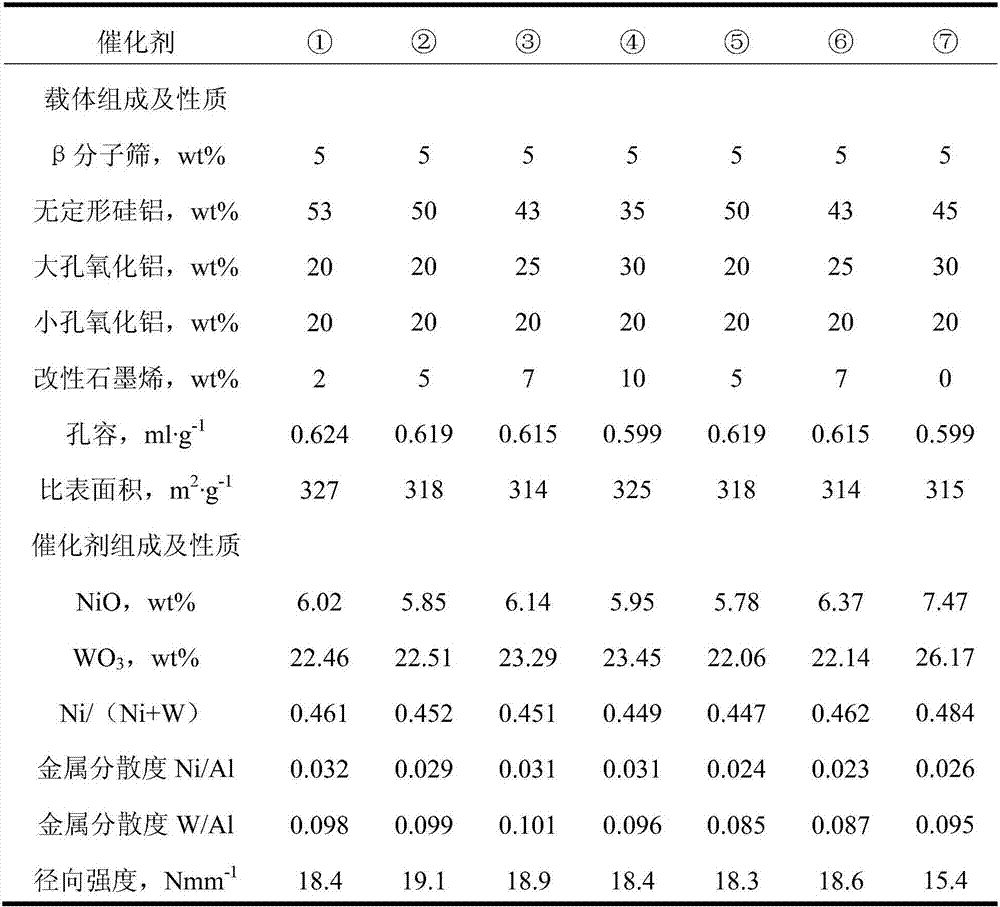

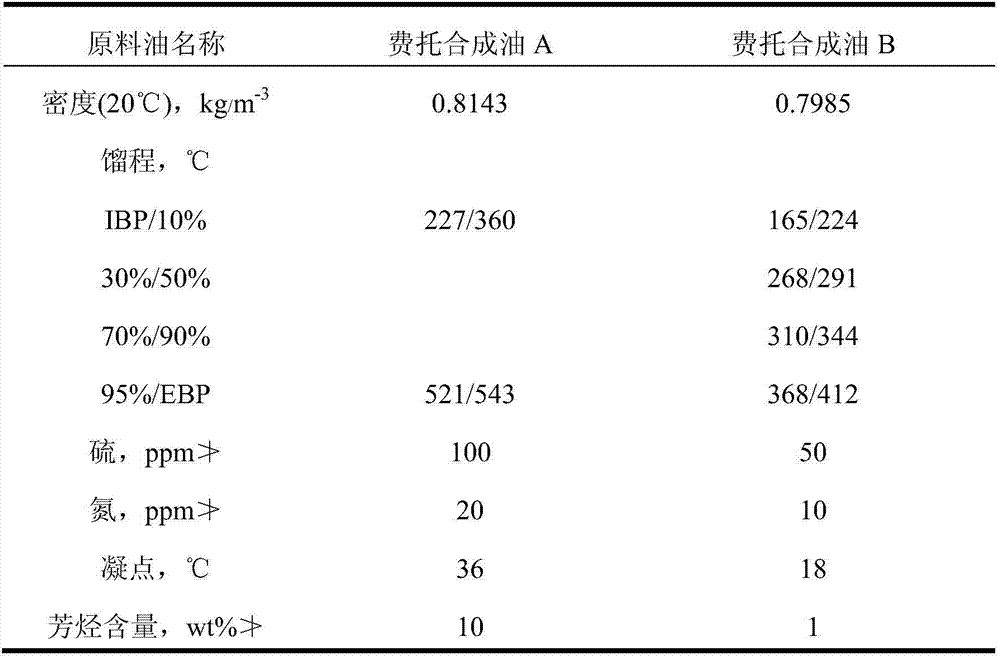

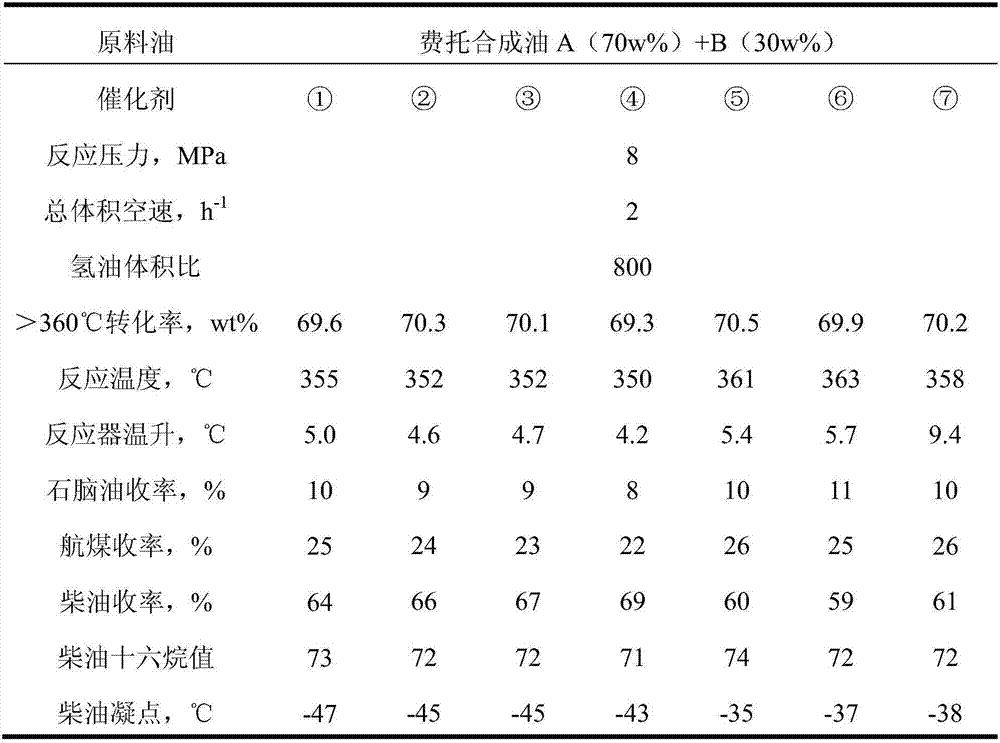

ActiveCN107362825AImprove thermal conductivityUniform temperature distributionMolecular sieve catalystsLiquid hydrocarbon mixture productionSesbaniaAluminium

The invention discloses a roasting-free hydrogenation catalyst and its preparation method and application. The roasting-free hydrogenation catalyst comprises a carrier and a metal active component. The metal active component is carried by a carrier. The roasting-free hydrogenation catalyst comprises 5-30% by weight of the metal active component. The metal active component comprises one or more of Co, Mo, Ni and W salts. The carrier is prepared from 1 to 10 parts by weight of a molecular sieve, 25 to 65 parts by weight of amorphous aluminum silicon, 30 to 65 parts by weight of alumina, 2 to 10 parts by weight of modified graphene and 0.5 to 1 part by weight of sesbania powder. The graphene greatly enhances the mechanical strength of the carrier and the catalyst. Through use of ZrO2 in the modified graphene, the metal distribution and active ammonium phase structure are improved, the active specific surface area of the carrier is improved and sulfur and nitrogen resistance and regeneration performances of the catalyst are improved.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Method for preparing sulfurization type hydro-cracking catalyst

ActiveCN103769200AIncreased degree of vulcanizationImprove hydrogenation performanceMolecular sieve catalystsHydrocarbon oil crackingNickel saltTungstate

The invention discloses a preparation method of a sulfurization type hydro-cracking catalyst. The preparation method comprises the following steps: selecting a hydro-cracking catalyst carrier component, wherein the carrier component at least comprises a molecular sieve and an amorphous acidic component; adding water into the carrier component powder, pulping so as to obtain slurry (c), then adding sulfo-molybdate and / or sulfo-tungstate slurry (a) and a nickel salt and / or cobalt salt solution (b) into the slurry (c), adding a surfactant at the same time, evenly mixing, filtering, washing, and drying in the protection of inert gas, adding an adhesive, kneading, forming, and finally drying and burning in the protection of inert gas so as to obtain the sulfurization type hydro-cracking catalyst. The preparation method makes the active metal be evenly distributed on the carrier so as to generate more II type Ni(Co)Mo(W)S active phases with a higher activity; thus the catalyst has a high sulfurization degree and a high utilization rate of active metal, the hydrogenation activity and acidity of the catalyst are more reasonably matched, so the hydrogenation activity and selectivity of the catalyst are both improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of sulfuration type hydro-cracking catalyst

ActiveCN103769199AIncreased degree of vulcanizationImprove utilization efficiencyMolecular sieve catalystsHydrocarbon oil crackingActive phaseAmmonium sulfide

The invention discloses a preparation method of a sulfuration type hydro-cracking catalyst. The preparation method comprises the following steps: selecting a carrier component of a hydro-cracking catalyst, wherein the carrier component comprises at least an acidic cracking component, adding water into the carrier component powder, pulping so as to obtain slurry (d), then adding an ammonium molybdate and / or ammonium tungstate solution (a), an ammonium sulfide solution (b), and a nickel salt and / or cobalt salt solution (c) into the slurry (d) to carry out reactions, filtering, washing and drying the reaction product in the protection of inert gas, adding an adhesive into the reaction product, kneading, forming, drying, and burning in the protection of inert gas so as to obtain the sulfurization type hydro-cracking catalyst. The preparation method makes the active metal be evenly distributed on the carrier so as to generate more II type Ni(Co)Mo(W)S active phases with a higher activity; thus the catalyst has a high sulfurization degree and a high utilization rate of active metal, so that the hydrogenation performance of the catalyst is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thermoplastic dynamic vulcanizate (TPV) material with excellent pressure change properties and preparation method of TPV

InactiveCN110437547AImprove pressure change performanceIncrease the degree of cross-linkingThermoplasticDynamic field

The invention belongs to the technical field of production of a thermoplastic elastomer, and particularly relates to a preparation technology of thermoplastic dynamic vulcanizate (TPV) with excellentpressure change properties. The problem that application requirements of dynamic products cannot be met due to too high permanent compression set of a part of TPV materials is solved mainly by using the preparation process of TPV through control on the use amount of a vulcanizing agent, the number of addition of the vulcanizing agent, the oil filling amount and the oil filling mode, so that the dynamic performance of existing TPV materials is optimized greatly; and finally the TPV material with excellent pressure change properties is obtained, and a positive promotion effect on application ofthe TPV material in the dynamic field is achieved.

Owner:青岛蓝湾烯碳材料科技有限责任公司

Low-temperature-resistant protective sleeve for underground cable

PendingCN113201188AImprove heat resistanceAccelerated corrosionEthylene-propylene-diene-monomerPlasticizer

The invention discloses a low-temperature-resistant protective sleeve for underground cables, and belongs to the technical field of cable protection. The protective sleeve is prepared from the following raw materials by weight: 20-30 parts of silicone rubber, 35-45 parts of ethylene propylene diene monomer, 2.5-3.5 parts of white carbon black, 5-8 parts of a vulcanizing agent, 2-5 parts of an accelerator, 3-8 parts of a plasticizer, and 2-4.5 parts of a flame retardant. Compared with a traditional cable protective sleeve and a preparation process thereof, the elongation at break of the protective sleeve at normal temperature reaches 678% or above, the tensile strength reaches 28.6 Mpa or above, and the mechanical performance is excellent; the low-temperature retraction temperature TR10 is -24.5 DEG C or below, and the low-temperature-resistant protective sleeve can keep good elasticity under the low-temperature condition and is suitable for being used in the low-temperature environment; and the oxygen index reaches 48 or above, the flame retardant property is good, the use requirement of the underground cable can be met, the cable can be used in a low-temperature environment, and the service life of the underground cable is prolonged.

Owner:国网河南省电力公司镇平县供电公司

High-elastic adhesive for coir mattress and preparation method thereof

InactiveCN105778823AIncrease vulcanization rateIncreased degree of vulcanizationNatural rubber adhesivesNon-macromolecular adhesive additivesMethacrylateSodium stearate

The invention relates to a high-elastic adhesive for coir mattress. The adhesive comprises the following ingredients (by weight): 200-300 parts of natural latex, 100-50 parts of sericin, 10-25 parts of magnesium methacrylate, 20-30 parts of 20% sodium stearate aqueous solution, 20-30 parts of dicumyl peroxide, 1-2 parts of a vulcanization accelerator, 2-3 parts of an anti-aging agent, 1-2 parts of a mildew inhibitor, 0.5-1 part of a flexibilizer and 80-100 parts of a dispersant. By the addition of magnesium methacrylate, vulcanization rate of natural latex can be accelerated, and degree of vulcanization is raised. Under the action of dicumyl peroxide, magnesium methacrylate can remarkably improve mechanical properties and thermal aging resistance of natural latex.

Owner:TIANJIN SHENGLONG RUBBERISED MATTRESS

Salt corrosion-resistant and torsion-resistant integral shielding telecommunication cable for offshore wind power and manufacturing method of integral shielding telecommunication cable

ActiveCN103227011AReduce tensionEliminate voidsInsulating conductors/cablesCables with twisted pairs/quadsCopper conductorTelecommunications cable

The invention relates to a salt corrosion-resistant and torsion-resistant integral shielding telecommunication cable for offshore wind power and a manufacturing method of the integral shielding telecommunication cable. Salt corrosion-resistant and torsion-resistant rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated wire cores; the insulated wire cores are stranded in pair to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; a plurality of groups of pair-twist wire pairs are stranded to form a cable core; and the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer, an inner jacket, a copper foil polyester composite belt shielding layer and an outer jacket sequentially from the inside out. The integral shielding telecommunication cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated wire core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated wire cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the inner jacket and the insulated wire cores are not adhered, so that the insulated wire cores are not damaged when the inner jacket is stripped during construction.

Owner:浙江华威设备制造有限公司

Rubber product used for packer

InactiveCN105199269AGuarantee of high temperature resistanceIncrease in sizePlasticizerCoiled tubing

The invention provides a rubber product used for a packer in petroleum drilling and production, belongs to the field of rubber products and aims at solving the problems that existing packers are poor in oil resistance, high temperature resistance and high pressure resistance, prone to being aged and in need of continuously replacement, labor amount is increased, and the working efficiency is lowered. The rubber product used for the packer is prepared from 140-180 parts of fluororubber 23, 5-20 parts of white carbon black; 40-50 parts of mica powder, 20-40 parts of fine particle calcium carbonate, 5-25 parts of zinc oxide, 4 parts of magnesia, 5-10 parts of fatty glyceride, 5-10 parts of accelerant DM, 1-5 parts of anti-aging agents NBC, 5-20 parts of vulcanizing agents BP and 5-10 parts of epoxy plasticizer. By means of the formula, the obtained rubber product is capable of being resistant to the high temperature of 250 DEG C and the pressure of 60 MPa, has excellent oil resistance and anti-aging performance and can be widely used in the spacer of a coiled tube in petroleum drilling and production.

Owner:成都棕通石油配件有限公司

High-elongation rubber for joint and preparation method of high-elongation rubber

ActiveCN113024958AHigh elongationImprove adhesionRolling resistance optimizationPolymer scienceVulcanization

The invention provides high-elongation rubber for a joint. The high-elongation rubber comprises the following components in parts by weight: 45-50 parts of ethylene propylene rubber, 30-45 parts of ethylene propylene diene monomer, 10-20 parts of liquid ethylene propylene rubber, 20-25 parts of zinc oxide, 50-55 parts of carbon black N330, 10-15 parts of paraffin oil 2280, 3.0-5.0 parts of an anti-aging agent and 2.0-7.0 parts of a vulcanizing agent. According to the invention, improvement is carried out on the basis of a common heat-resistant rubber formula, the liquid ethylene propylene rubber is added at the same time, and the loss of an anti-aging agent in the ethylene propylene rubber vulcanization process is changed through a correct anti-aging agent ratio, so that the anti-aging agent can inhibit the heat effect to the maximum extent, thereby maintaining the high elongation of the ethylene propylene rubber after aging and prolonging the service life of the rubber; and moreover, the rubber is not obviously changed after being aged for 800000 times of dynamic tests, that is, the rubber with high elongation is only gradually weakened by the elongation force instead of being directly applied to the stripping force under the same acting force, so that the aim of keeping the adhesive property unchanged after the rubber is aged can be achieved.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com