Environment-friendly anti-blooming ethylene propylene rubber compound

A technology of ethylene-propylene rubber and mixed rubber, which is applied in the field of rubber, which can solve the problems of human health damage, frosting and whitening of the surface of products with accelerators, and oil injection, etc., to achieve the effect of increasing vulcanization speed and excellent appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

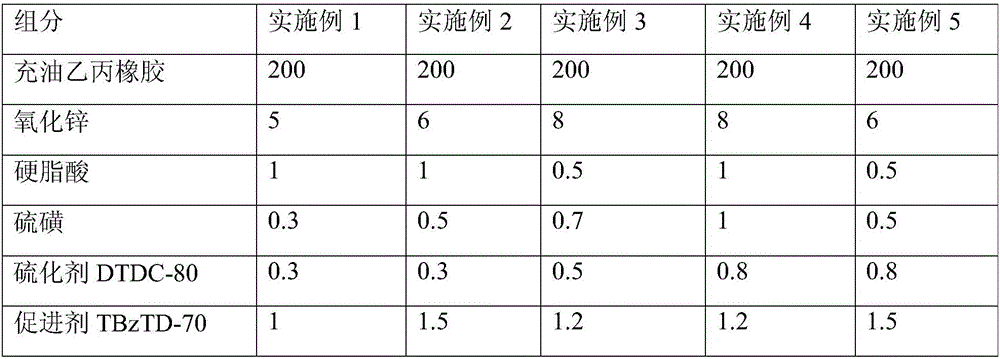

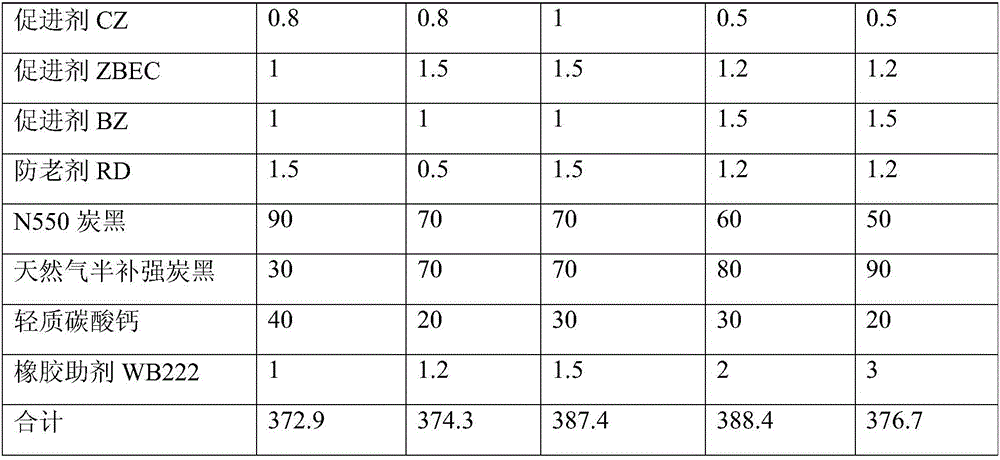

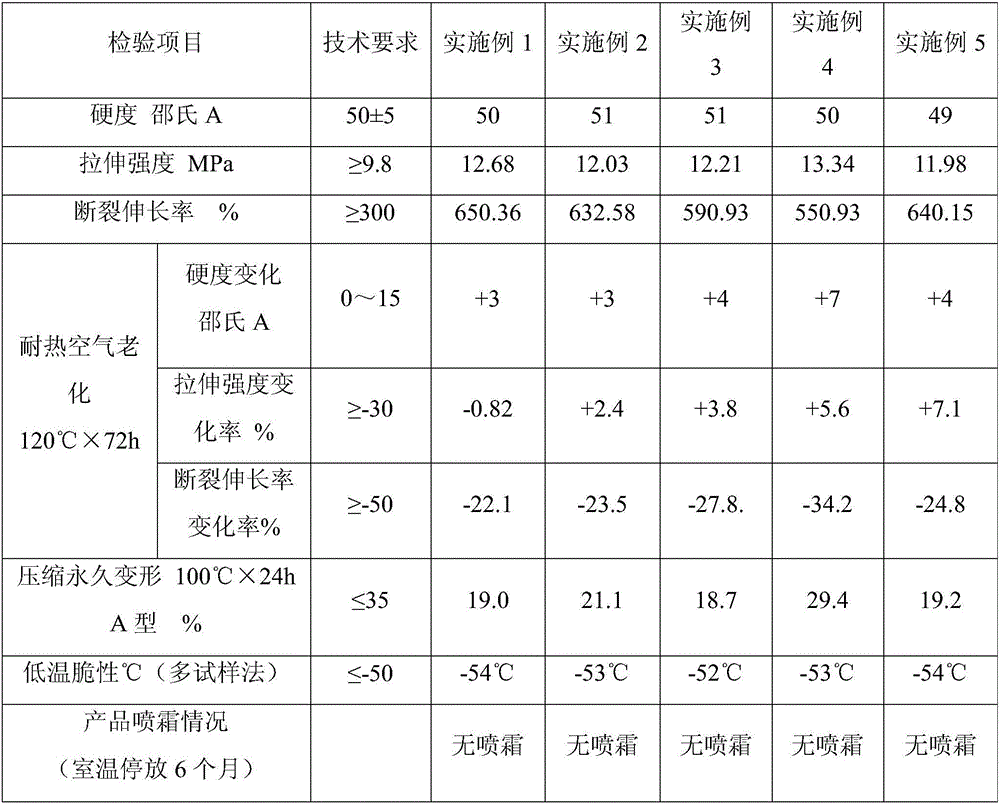

[0015] The technical solutions of the present invention will be further described below through specific embodiments.

[0016] According to Table 1, each raw material component was weighed, and the ethylene-propylene rubber compound was prepared according to the following method: masticate oil-extended ethylene-propylene rubber (LANXESS EPDM5469Q) on an open mill for 2 minutes at room temperature, and add fine Materials (zinc oxide, stearic acid, antioxidant RD, TBzTD-70, accelerator CZ, accelerator ZBEC and accelerator BZ), N550 carbon black, natural gas semi-reinforcing carbon black, light Calcium carbonate and other fillers were mixed for 5 minutes, and finally sulfur, vulcanizing agent DTDC-80, and flow aid WB222 were added and mixed for 3 minutes. After parking at room temperature for 1 day, vulcanize on a flat vulcanizing machine with a vulcanization temperature of 160°C, a vulcanization pressure of 13Mpa, and a vulcanization time of 15 minutes.

[0017] Table 1 Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com