TPV material and preparation method and application thereof

A mass ratio, peroxide technology, applied in the field of polymer materials, can solve the problems of jagged edges, rough surfaces, and difficulty in achieving fineness, etc., to achieve fine product surfaces, improve surface roughness, and meet strict compression The effect of permanent deformation physical property requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

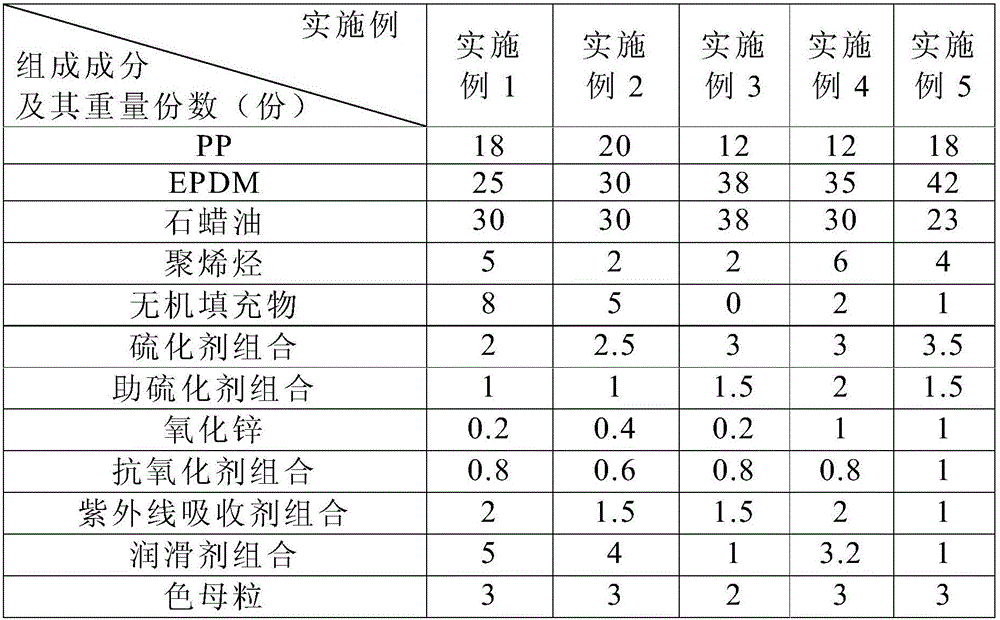

Examples

Embodiment 1

[0035] Compatible raw materials according to the composition and parts by weight of Example 1 in Table 1, wherein the polyolefin is an ethylene-butylene copolymer, the inorganic filler is talcum powder, and the vulcanizing agent combination is DCP and TBICM75 compounded at 2:1 , the combination of co-vulcanizing agent is TMPTMA and modified polybutadiene in a ratio of 2:3, the combination of antioxidant is a compound of antioxidant 1010 and antioxidant 168 in a ratio of 1:1, and the combination of ultraviolet absorber is UV 2908 , UV 3853, and UV5411 are compounded at a ratio of 1:0.5:2, and the lubricant combination is PE wax, stearic acid, and PPA compounded at a ratio of 2:2:0.1.

[0036] Then add EPDM, ethylene-butylene copolymer, paraffin oil inorganic filler, and part of PP in the above raw materials into the hopper of the twin-screw extruder with a length-to-diameter ratio of 48:1 through loss-in-weight feeding, and the feeding amount is 500KG / h, under the conditions o...

Embodiment 2

[0039] Compatible raw materials according to the composition and parts by weight of Example 1 in Table 1, wherein the polyolefin is ethylene-butylene copolymer, the inorganic filler is talcum powder, and the vulcanizing agent combination is DCP and TBICM75 compounded in 2:3 , the combination of co-vulcanizing agent is TMPTMA and modified polybutadiene in a ratio of 2:4, the combination of antioxidant is a compound of antioxidant 1076 and antioxidant 168 in a ratio of 1:1, and the combination of ultraviolet absorber is UV 2908 , UV 3853, and UV5411 are compounded at a ratio of 1:0.5:2, and the lubricant combination is PE wax, stearic acid, and PPA compounded at a ratio of 2:2:0.1.

[0040]Then add EPDM, ethylene-butylene copolymer, paraffin oil, inorganic filler, and part of PP in the above raw materials into the hopper of the twin-screw extruder with a length-to-diameter ratio of 48:1 through loss-in-weight feeding, and the feeding amount is 500KG / h, melt blending under the co...

Embodiment 3

[0043] Compatible raw materials according to the composition and parts by weight of Example 1 in Table 1, wherein the polyolefin is an ethylene-butylene copolymer, the inorganic filler is talcum powder, and the vulcanizing agent is combined with BIPB and TBICM75 according to 2:2 , the combination of co-vulcanizing agent is TMPTMA and modified polybutadiene in a ratio of 2:3, the combination of antioxidant is a compound of antioxidant 1010 and antioxidant 168 in a ratio of 1:1, and the combination of ultraviolet absorber is UV 2908 , UV 3853, and UV5411 are compounded at a ratio of 1:0.5:2, and the lubricant combination is PE wax, stearic acid, and PPA compounded at a ratio of 2:2:0.1.

[0044] Then add EPDM, ethylene-butylene copolymer, paraffin oil, inorganic filler, and part of PP in the above raw materials into the hopper of the twin-screw extruder with a length-to-diameter ratio of 48:1 through loss-in-weight feeding, and the feeding amount is 500KG / h, melt blending under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com