Roasting-free hydrogenation catalyst and its preparation method and application

A hydrogenation catalyst, roasting-free technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Insufficient stability and other problems, to achieve obvious thermal conductivity advantages, increase the active specific surface, improve the performance of sulfur and nitrogen resistance and regeneration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] 1, the preparation method of modified graphene, concrete steps are as follows:

[0059] 101) The mass fraction of 1g natural graphite, 1g anhydrous sodium nitrate and 50ml is 98% concentrated sulfuric acid;

[0060] 102) Slowly put natural graphite and anhydrous sodium nitrate into concentrated sulfuric acid placed in an ice bath, slowly add 6 g of potassium permanganate for oxidation treatment, and stir for 0.5-2 hours to obtain a mixed solution;

[0061] 103) Place the mixed solution in a water bath at a temperature of 35° C., stir for 2 hours, and slowly add 200 ml of deionized water to the mixed solution during the stirring process;

[0062] 104) Then place the mixed solution in an oil bath with a temperature of 98° C., continue to stir and react for 0.5 h, then dilute the mixed solution with deionized water to 400 ml to obtain a diluted solution;

[0063] 105) Slowly add 30ml of hydrogen peroxide with a mass fraction of 30% to the diluted solution, and filter whil...

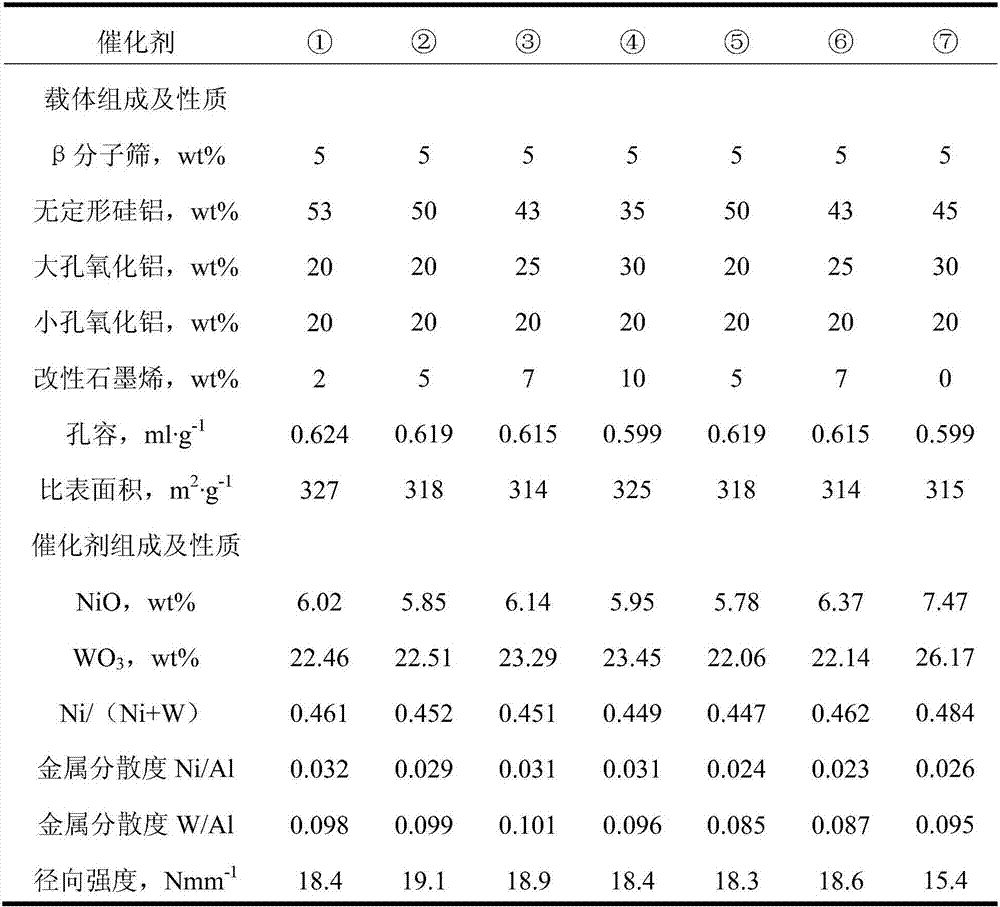

Embodiment 1

[0076] The preparation method of carrier ①, the specific steps are as follows:

[0077] 1) Weigh 0.5g of β molecular sieve, 5.3g of amorphous silica-alumina, 2.0g of macroporous alumina, 0.2g of modified graphene, and 0.1g of squash powder;

[0078] 2) macroporous alumina, β molecular sieve, amorphous silica-alumina, modified graphene and squat powder were mixed in a kneader for 15 minutes to obtain a mixture;

[0079] 3) Weighing 2g of small-pore alumina and 6g of nitric acid solution with a mass fraction of 4% and mixing them uniformly as a binder;

[0080] 4) Add 8g of adhesive to the obtained mixture, knead for 30min, transfer to extruder for extrusion molding, then freeze-dry it for 20h, and cut into pellets;

[0081] 5) Place the freeze-dried mixture of molded pellets in an air atmosphere, then bake at 500°C for 4 hours, and then cool to room temperature to make a carrier ①;

[0082] The preparation method of selective hydrogenation catalyst ①, concrete steps are as fo...

Embodiment 2

[0086] The preparation method of carrier ②, concrete steps are as follows:

[0087] 1) Weigh 0.5g of beta molecular sieve, 5.0g of amorphous silica-alumina, 2.0g of macroporous alumina, 0.2g of modified graphene, and 0.1g of squid powder;

[0088] 2) macroporous alumina, β molecular sieve, amorphous silica-alumina, modified graphene and squat powder were mixed in a kneader for 15 minutes to obtain a mixture;

[0089] 3) Weighing 2g of small-pore alumina and 6g of nitric acid solution with a mass fraction of 4% and mixing them uniformly as a binder;

[0090] 4) Add 8g of adhesive to the obtained mixture, knead for 30min, transfer to extruder for extrusion molding, then freeze-dry it for 20h, and cut into pellets;

[0091] 5) Place the freeze-dried mixture of molded pellets in an air atmosphere, then bake at 500°C for 4 hours and then cool to room temperature to make a carrier ②;

[0092] The preparation method of selective hydrogenation catalyst ②, concrete steps are as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com