Thermoplastic dynamic vulcanizate (TPV) material with excellent pressure change properties and preparation method of TPV

An excellent and high-performance technology, applied in the field of TPV material and its preparation, can solve the problem of high compression set cannot meet the dynamic product application and other problems, and achieve the effect of optimizing dynamic performance, reducing compression set and increasing cross-linking density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

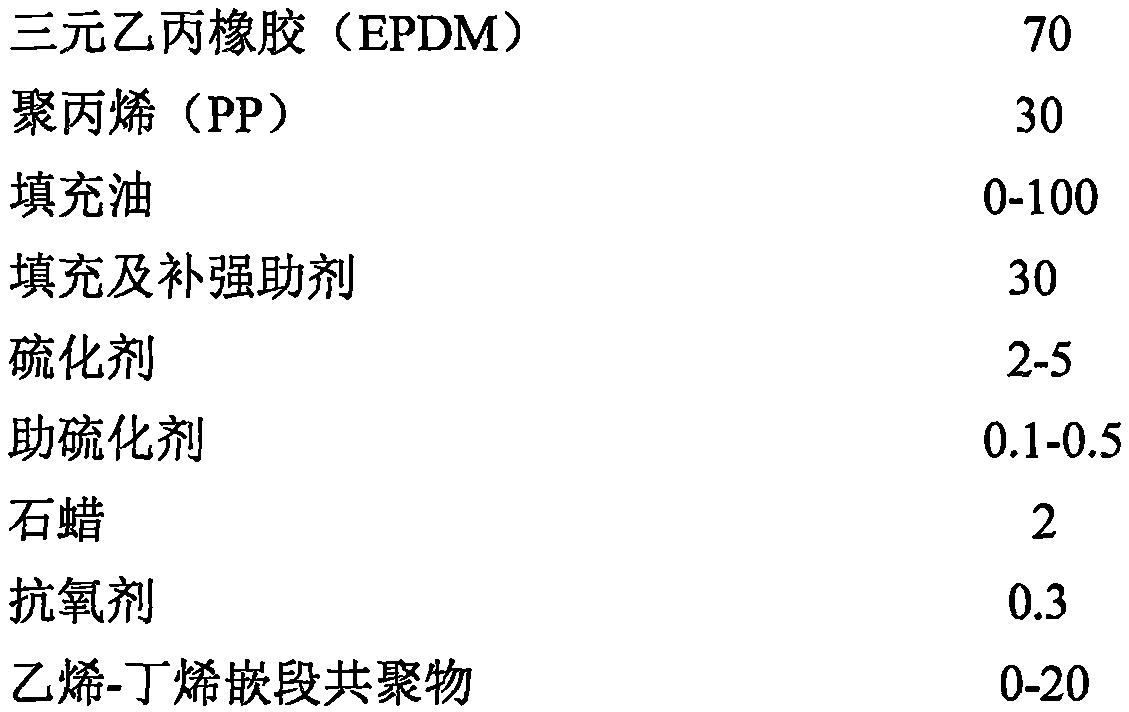

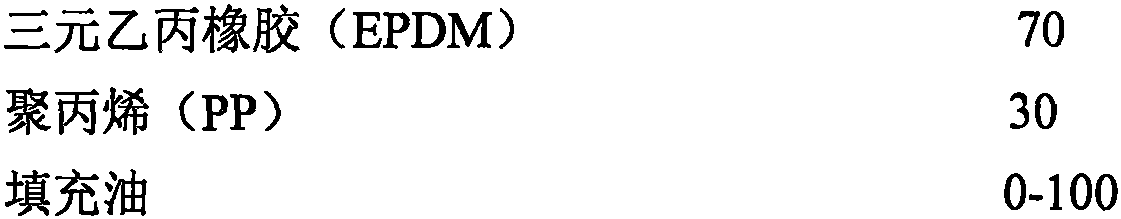

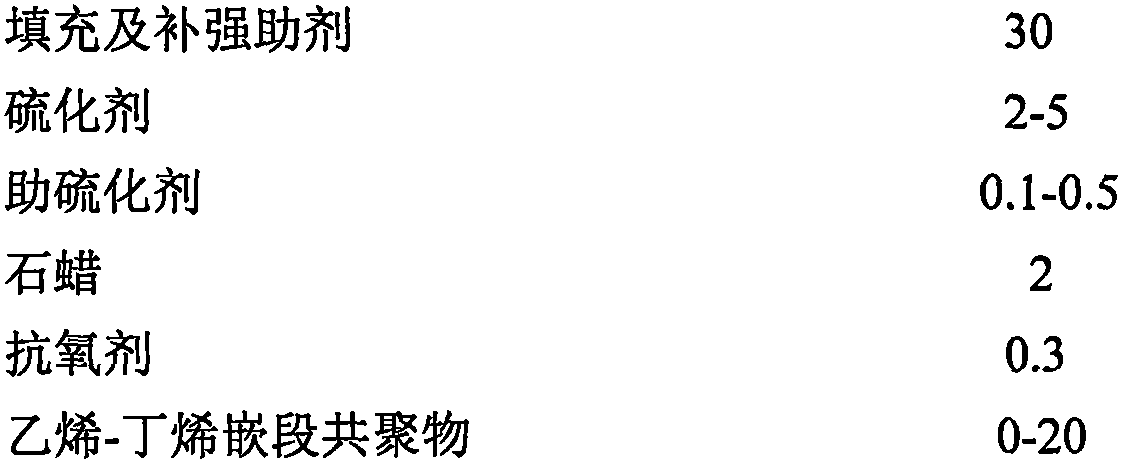

Method used

Image

Examples

Embodiment 1

[0026] A kind of TPV material with excellent pressure change performance and preparation method thereof, its formula consists of (weight parts), EPDM70, PP 30, calcium carbonate 30, paraffin oil 30, vulcanizing agent DCP 2, TMPTMA 0.2, paraffin wax 2, antioxidant Agent 0.3, other 5.

[0027] Its preparation method is as follows: firstly, EPDM, PP, calcium carbonate, 1 / 2 paraffin oil and all other processing aids except DCP and TMPTMA are added to the internal mixer in sequence for mechanical mixing to obtain a uniformly mixed product. The compound rubber is then carried out single-screw extrusion granulation by forced feeding and then sent to the twin-screw extruder, and DCP, TMPTMA and the remaining 1 / 2 paraffin oil are added in the middle of the twin-screw extrusion process, and the screw extrusion is set. The output temperature is 190°C, the rotation speed is adjusted, and then the finished TPV material is obtained after twin-screw extrusion and drying.

Embodiment 2

[0029] A kind of TPV material with excellent pressure change performance and preparation method thereof, its formula consists of (weight parts), EPDM70, PP 30, calcium carbonate 30, paraffin oil 30, vulcanizing agent DCP 2, TMPTMA 0.2, paraffin wax 2, antioxidant Agent 0.3, other 5.

[0030] The preparation method is as follows: first, EPDM, PP, calcium carbonate, paraffin oil and all other processing aids except DCP and TMPTMA are added to the internal mixer in order to carry out mechanical mixing to obtain a uniformly mixed mixture. Then carry out single-screw extrusion granulation through forced feeding, and then send it into the twin-screw extruder, and add DCP and TMPTMA in the middle of the twin-screw extrusion process, set the extrusion temperature of the screw to 190 ° C, adjust the speed, and then pass through the twin-screw extruder. The finished TPV material is obtained after screw extrusion and drying.

Embodiment 3

[0032] A kind of TPV material with excellent pressure change performance and preparation method thereof, its formula consists of (weight parts), EPDM70, PP 30, calcium carbonate 30, paraffin oil 30, vulcanizing agent DCP 2.4, TMPTMA 0.24, paraffin wax 2, antioxidant Agent 0.3, other 5.

[0033] The preparation method is as follows: first, EPDM, PP, calcium carbonate, paraffin oil and all other processing aids except DCP and TMPTMA are added to the internal mixer in order to carry out mechanical mixing to obtain a uniformly mixed mixture. Then carry out single-screw extrusion granulation through forced feeding, and then send it into the twin-screw extruder, and add DCP and TMPTMA in the middle of the twin-screw extrusion process, set the extrusion temperature of the screw to 190 ° C, adjust the speed, and then pass through the twin-screw extruder. The finished TPV material is obtained after screw extrusion and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com