Polyurethane rubber roller and preparation method thereof

A technology of polyurethane and rubber rollers, applied in the field of rubber rollers, can solve the problems of poor heat resistance, wear resistance and pressure change performance, and achieve the effects of high wear resistance and pressure change performance, good resilience, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

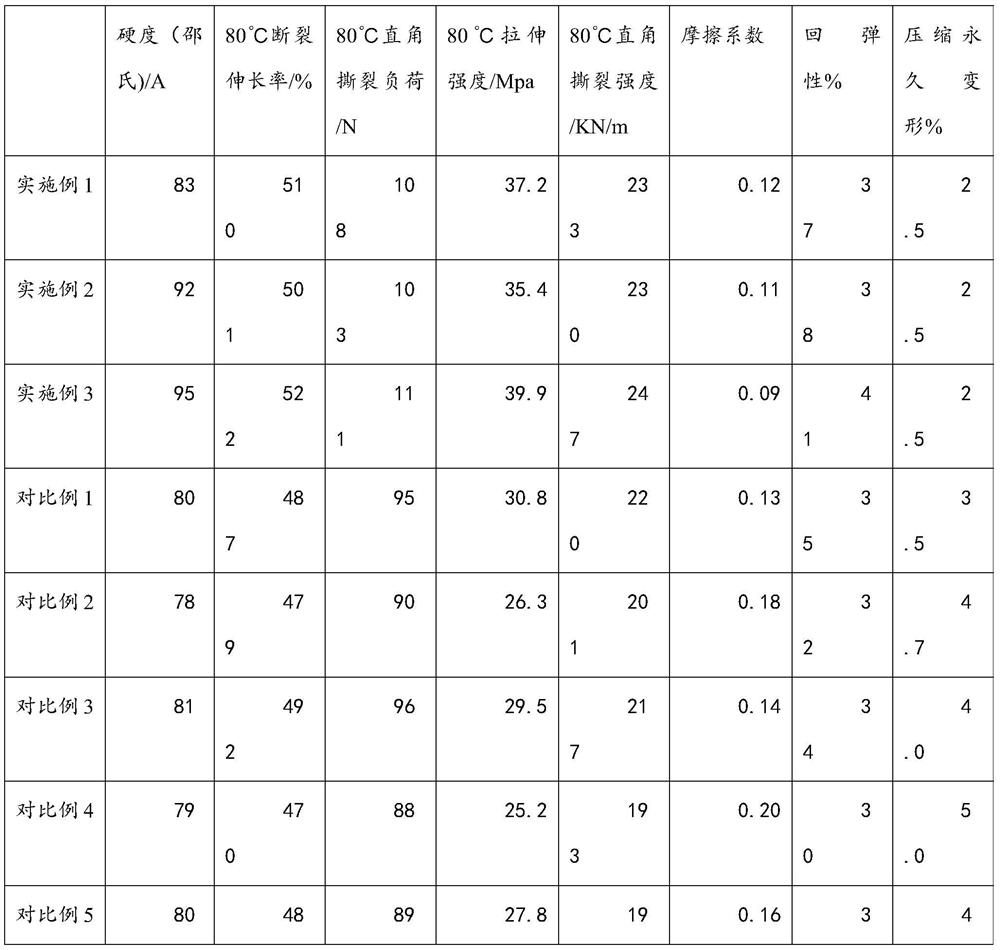

Examples

Embodiment 1

[0023] A polyurethane rubber roller is composed of the following components in parts by weight: 90 parts of polyether polyol, 15 parts of isocyanate compound, 5 parts of graphite, 5 parts of dioctyl adipate, and 15 parts of di-o-chloroaniline methane.

[0024] The preparation method of embodiment 1 comprises the following steps:

[0025] (1) Dehydration of polyether polyol, the temperature of dehydration is 120°C, and the time is 10 hours, adding isocyanate compound, the temperature is controlled at 150°C, mixed reaction to prepare semi-prepolymer;

[0026] (2) Graphite is dispersed by dioctyl adipate, added in the semi-prepolymer of step (1) gained;

[0027] (3) Add di-o-chloroaniline methane into the mixture of step (2) and stir evenly, react for 3 hours, and remove it under vacuum at -0.09MPa until there is no bubble, inject it into the mold, inject it into the mold, and vulcanize for 20 hours to release the mold.

[0028] The molecular weight of the polyether polyol is 80...

Embodiment 2

[0031] A polyurethane rubber roller is composed of the following components in parts by weight: 70 parts of polyether polyol, 10 parts of isocyanate compound, 2 parts of graphite, 10 parts of dioctyl adipate, and 25 parts of di-o-chloroaniline methane.

[0032] The preparation method of embodiment 2 comprises the following steps:

[0033] (1) Dehydration of polyether polyol, the temperature of dehydration is 110 DEG C, the time is 13 hours, adding isocyanate compound, the temperature is controlled at 120 DEG C, and mixed reaction is obtained semi-prepolymer;

[0034] (2) Graphite is dispersed by dioctyl adipate, added in the semi-prepolymer of step (1) gained;

[0035] (3) Add di-o-chloroaniline methane into the mixture of step (2) and stir evenly, react for 5 hours, and remove it under -0.1MPa vacuum until there is no bubble, inject it into the mold, inject it into the mold, vulcanize for 14 hours and release the mold.

[0036] The molecular weight of the polyether polyol is...

Embodiment 3

[0039] A polyurethane rubber roller is composed of the following components in parts by weight: 80 parts of polyether polyol, 13 parts of isocyanate compound, 3 parts of graphite, 8 parts of dioctyl adipate, and 20 parts of di-o-chloroaniline methane.

[0040] The preparation method of embodiment 3, comprises the following steps:

[0041] (1) Dehydration of polyether polyol, the dehydration temperature is 115 ° C, the time is 12 hours, adding isocyanate compound, the temperature is controlled at 130 ° C, mixed reaction to obtain a semi-prepolymer;

[0042] (2) Graphite is dispersed by dioctyl adipate, added in the semi-prepolymer of step (1) gained;

[0043] (3) Add di-o-chloroaniline methane into the mixture of step (2) and stir evenly, react for 4 hours, and remove it under -0.1MPa vacuum until there is no bubble, inject it into the mold, inject it into the mold, vulcanize for 18 hours and release the mold.

[0044] The molecular weight of the polyether polyol is 1000, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com