High-flame-retardant organic silicon foam sheet and preparation method thereof

A silicone, high flame retardant technology, applied in the direction of structural parts, battery pack parts, electrical components, etc., can solve the problem of poor tear resistance and pressure change performance, failure to meet the requirements of lithium batteries, and poor flame retardant performance and other problems, to achieve the effect of excellent cushioning performance, good pressure change performance and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

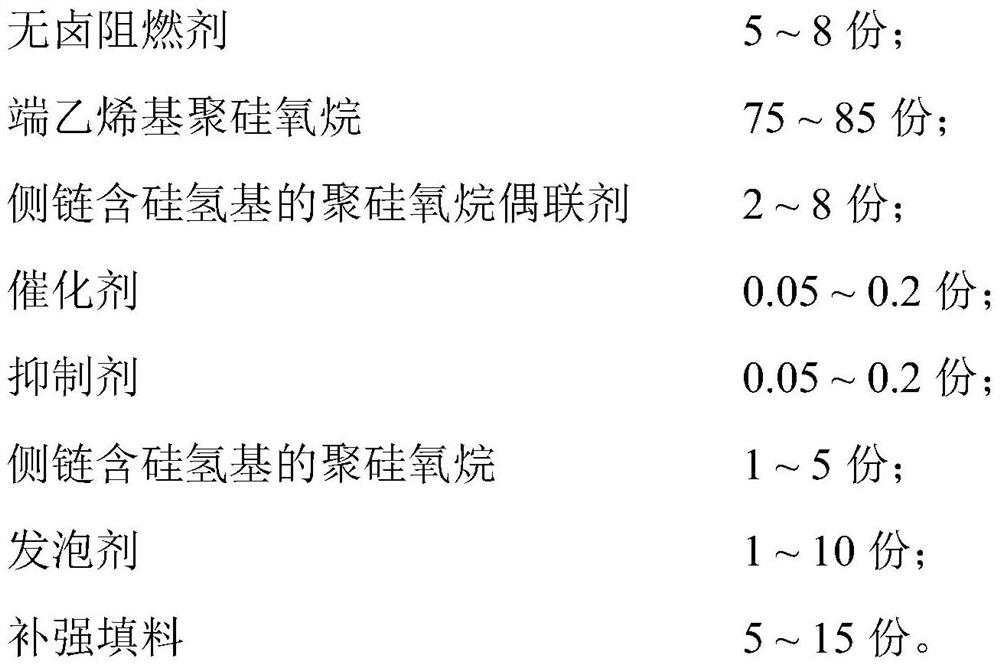

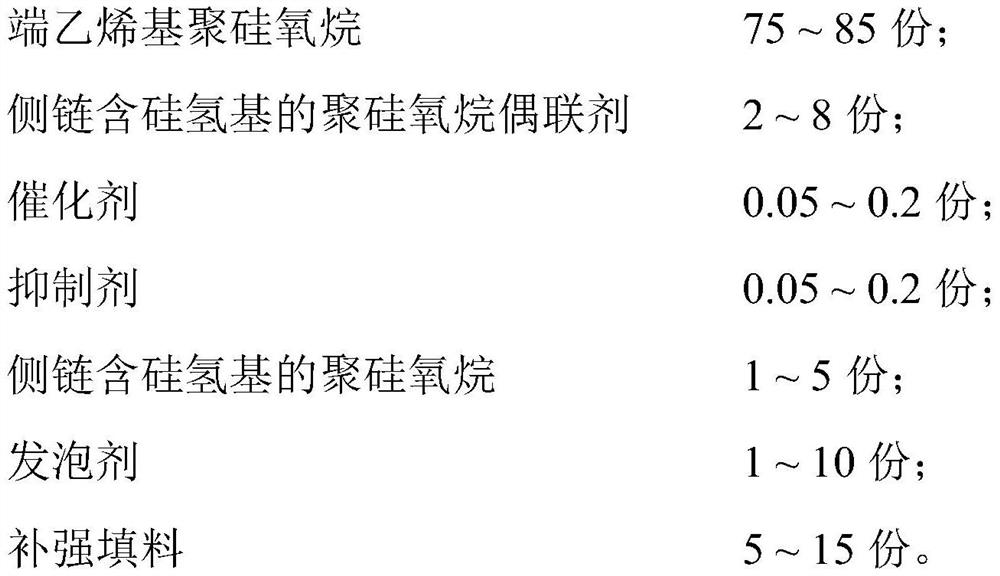

Method used

Image

Examples

Embodiment 1

[0034] The preparation of silicone foam includes the following specific steps

[0035] 1) Preparation of inorganic flame retardant coated with side chain hydrogen polysiloxane coupling agent

[0036] Weigh 16g of inorganic flame retardant, pour it into 1000mL of toluene, heat it in an oil bath at 60°C, and stir it with a high-speed stirrer at a speed of 1200rpm / min for 3min; then add 74g of side chain hydropolysiloxane coupling agent and stir 5 minutes; then, add 18 g of deionized water and stir for 8 minutes to initiate hydrolysis of the side chain hydrogen polysiloxane coupling agent, thereby forming a coating on the surface of the inorganic flame retardant. After the reaction is finished, filter and take the obtained side-chain hydrogen-based polysiloxane coupling agent-coated inorganic flame retardant particles and wash with 300ml of deionized water for 3 times, and then wash with 300ml of ethanol for 3 times. Subsequently, the particles were placed in a blast drying oven...

Embodiment 2

[0048] The difference between Example 2 and Example 1 is that the other halogen-free flame retardants in step 2.1) are 5 g of melamine pyrophosphate and 1 g of aluminum hypophosphite.

Embodiment 3

[0050] The difference between Example 3 and Example 1 is that the inorganic flame retardant in step 1) selects flame retardant vitrified powder, and the other halogen-free flame retardants in step 2.1) are 5g of pyrophosphate piperazine and 1g of aluminum hypophosphite .

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com