Ablation-resisting light silicone rubber thermal insulation coating

A heat-insulating coating and ablation-resistant technology, which is applied in coatings and other directions, can solve problems such as the difficulty in meeting the lightweight requirements of the aerospace field, the low bonding strength between ablation products and the substrate, and the inability to withstand mechanical vibrations caused by pneumatic scouring, etc., to achieve Short vulcanization time, high production efficiency, and reduced density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

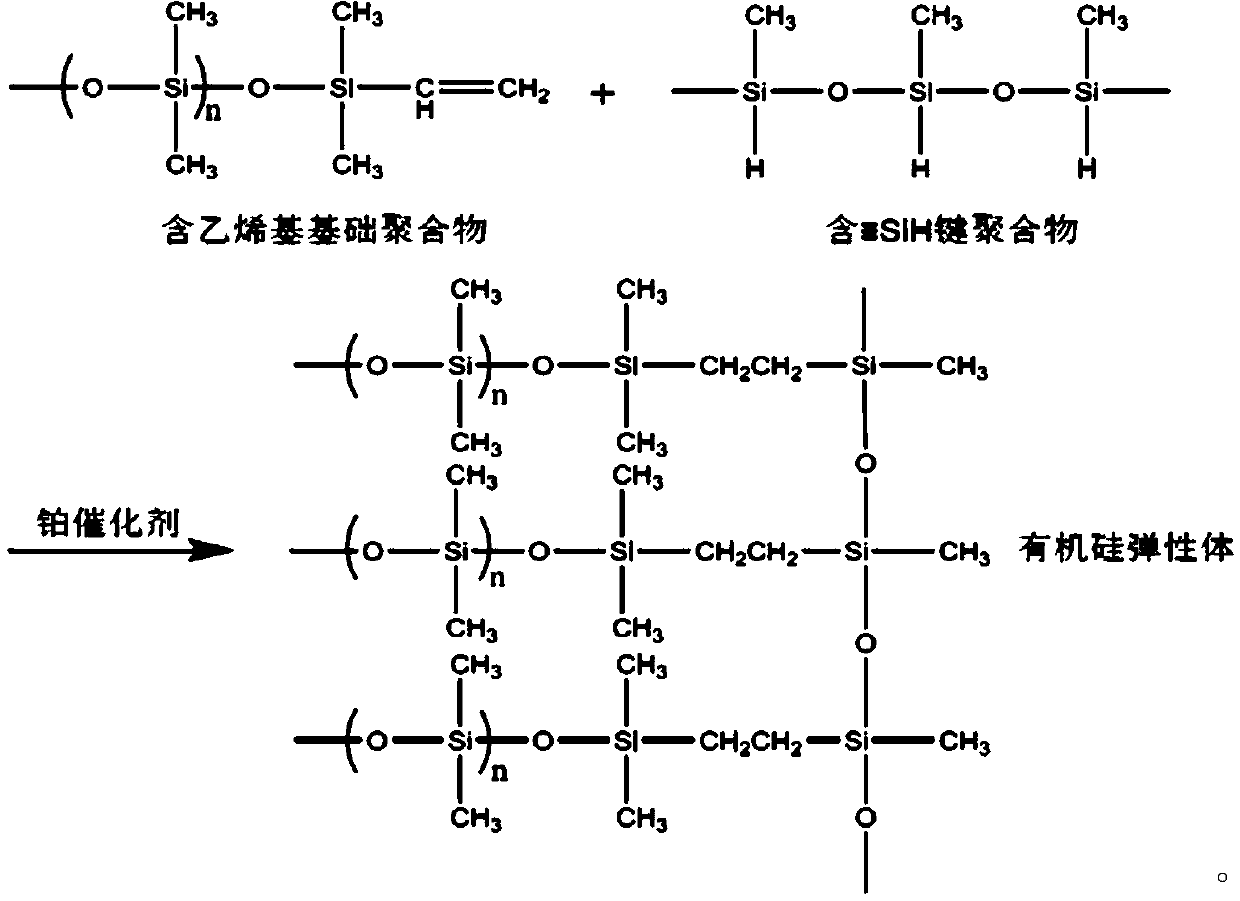

Method used

Image

Examples

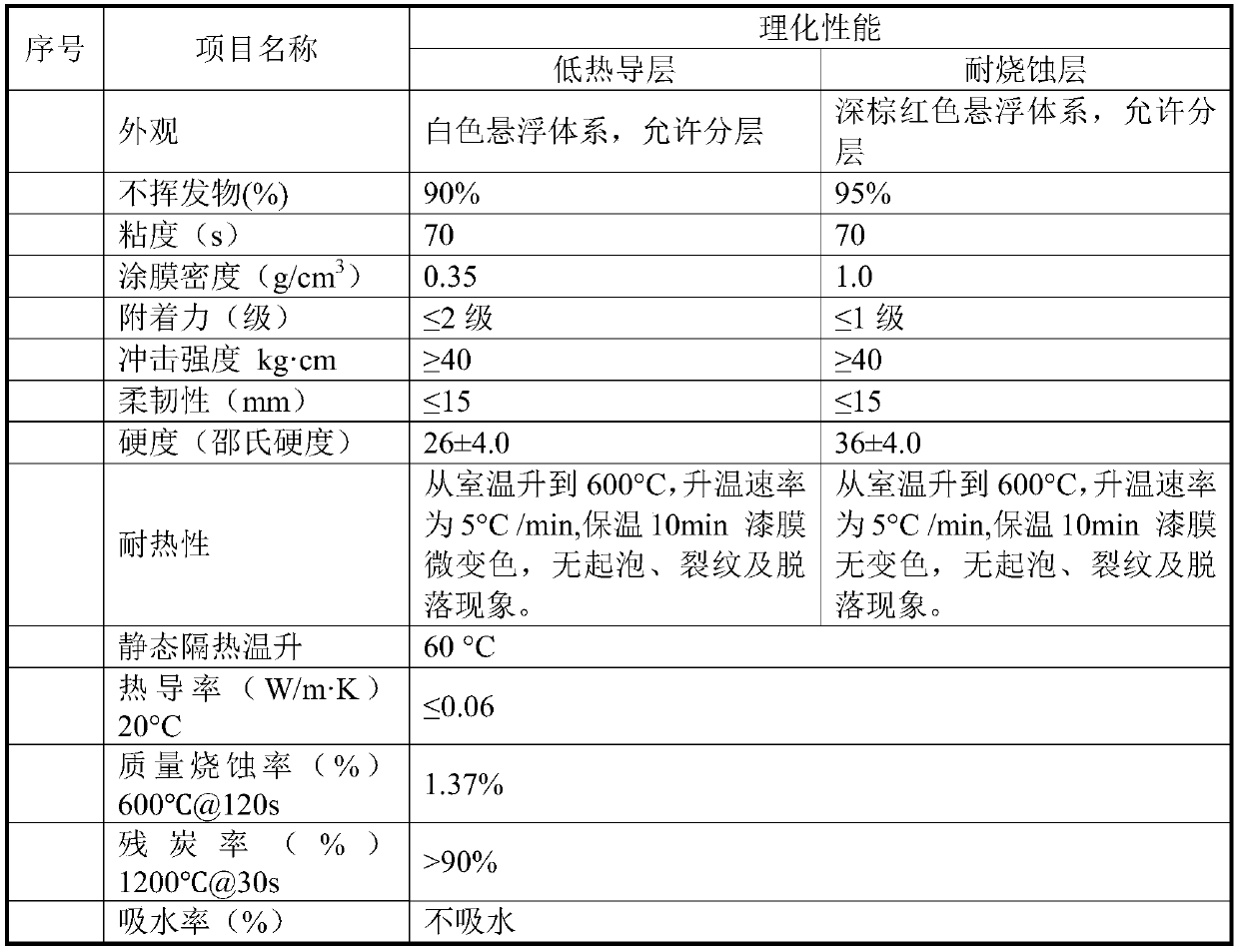

Embodiment 1

[0040] In order to achieve the above object, the present invention is achieved through the following technical solutions:

[0041] The ablation-resistant lightweight silicone rubber heat-insulating coating has a heat-insulating structure with two layers of heat-insulating structure: the outer layer is the ablation-resistant layer, which is taken away by the mass loss caused by physical changes or chemical reactions (generally, gas produced by decomposition reactions) Pray for heat insulation effect; the inner layer is a low thermal conductivity layer, which reduces longitudinal heat conduction through extremely low thermal conductivity, thereby reducing the temperature of the substrate. Each coat of paint consists of three components. The thickness ratio of the anti-ablation layer and the low thermal conductivity layer material is 5:1.

[0042] (1) Preparation and ratio of low thermal conductivity layer

[0043] The main components of the insulation layer include A, B and C ...

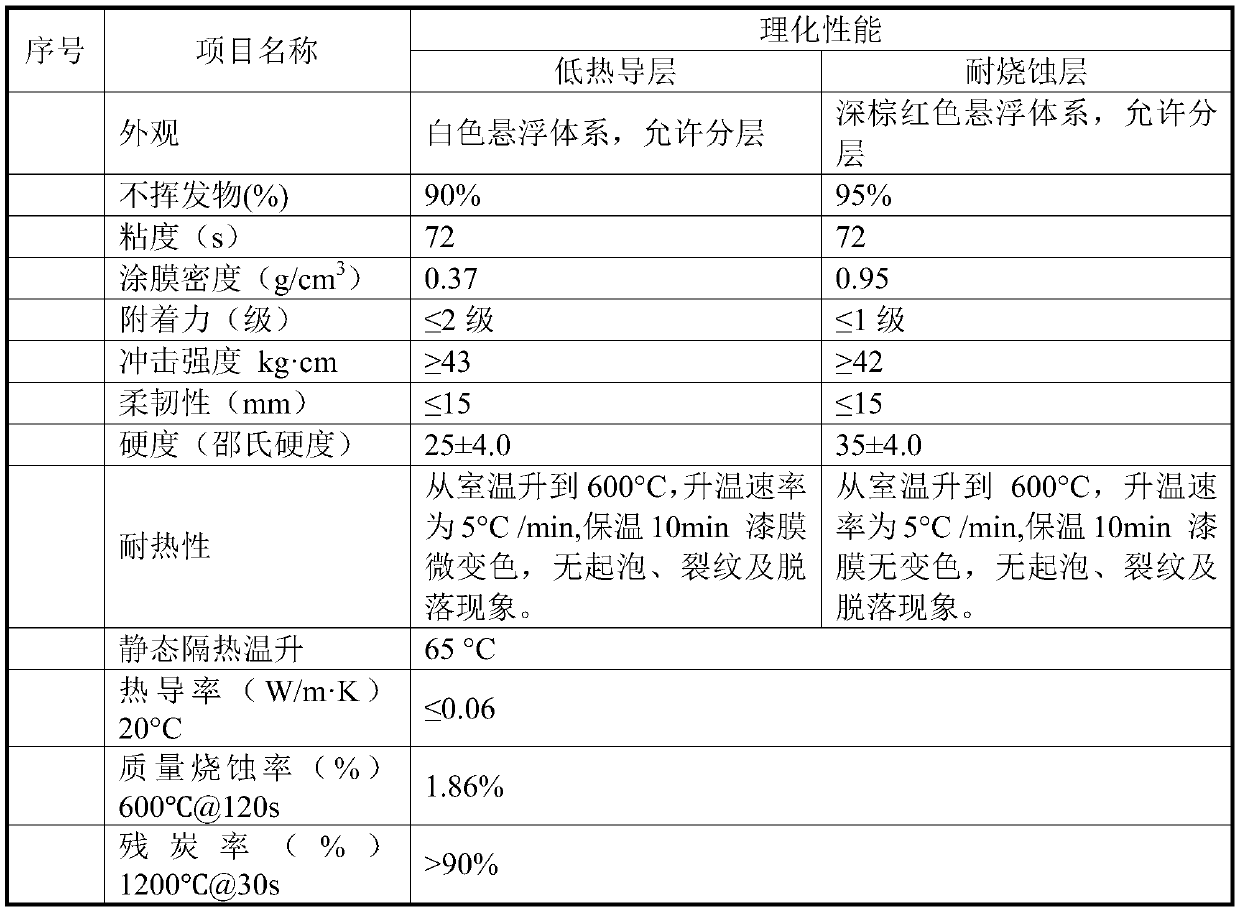

Embodiment 2

[0083] The ablation-resistant lightweight silicone rubber heat-insulating coating has a heat-insulating structure with two layers of heat-insulating structure: the outer layer is the ablation-resistant layer, which is taken away by the mass loss caused by physical changes or chemical reactions (generally, gas produced by decomposition reactions) Pray for heat insulation effect; the inner layer is a low thermal conductivity layer, which reduces longitudinal heat conduction through extremely low thermal conductivity, thereby reducing the temperature of the substrate. Each coat of paint consists of three components. The thickness ratio of the material of the ablation-resistant layer and the low thermal conductivity layer is 10:1.

[0084] (1) Preparation and ratio of low thermal conductivity layer

[0085] The main components of the low thermal conductivity layer include A, B and C components. The ingredients of component A are as follows: 60 parts of vinyl polysiloxane and 0.0...

Embodiment 3

[0112] The ablation-resistant lightweight silicone rubber heat-insulating coating has a heat-insulating structure with two layers of heat-insulating structure: the outer layer is the ablation-resistant layer, which is taken away by the mass loss caused by physical changes or chemical reactions (generally, gas produced by decomposition reactions) Pray for heat insulation effect; the inner layer is a low thermal conductivity layer, which reduces longitudinal heat conduction through extremely low thermal conductivity, thereby reducing the temperature of the substrate. Each coat of paint consists of three components. The thickness ratio of the anti-ablation layer and the material of the low thermal conductivity layer is 8:5.

[0113] (1) Preparation and ratio of low thermal conductivity layer

[0114] The main components of the insulation layer include A, B and C components. The ingredients of component A are as follows: 70 parts of vinyl polysiloxane and 0.06 parts of chloropla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com