Rubber syringe needle protective cap for pre-encapsulation injection syringe and production method thereof

A technology for a needle cap and a syringe, which is applied to the rubber needle cap for pre-filled syringes and the production field thereof, can solve the problem that the ultraviolet absorbance of the finished product, the reducing substance and the pH change value easily exceed the standard, the production process is complicated and tedious, and the rubber cap is sprayed. Sulfur" and other problems, to achieve the effect of improving lubricity and chemical inertness, reducing odor problems, and increasing the degree and speed of vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

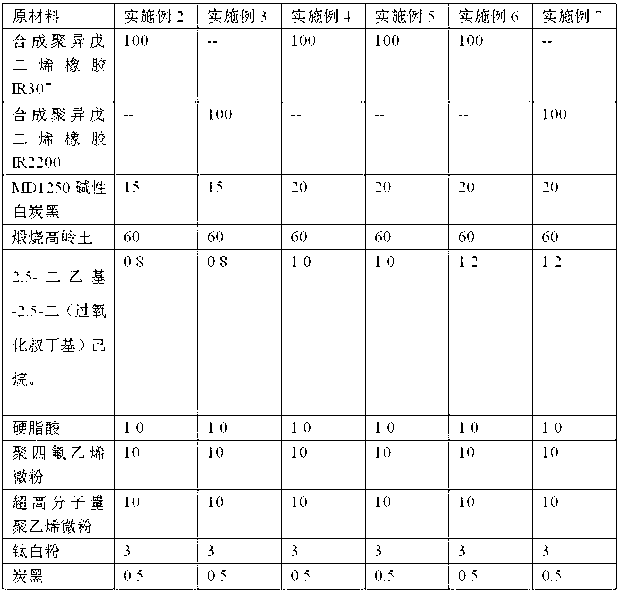

Examples

Embodiment 1

[0023] Example 1: A rubber needle protective cap for prefilled syringes, the production steps are as follows: A. Ingredients: Accurately weigh 100 parts by weight of synthetic polyisoprene rubber, 20 parts by weight of MD1250 basic white carbon black, and calcined kaolin 50 parts by weight, 1.0 parts by weight of peroxide, 1.0 parts by weight of stearic acid, 5 parts by weight of polytetrafluoroethylene micropowder, 10 parts by weight of ultra-high molecular weight polyethylene micropowder, 3 parts by weight of titanium dioxide, 0.5 parts by weight of carbon black, for subsequent use .

[0024] B. Internal mixing: Use a powerful pressurized internal mixer with a capacity of 55 liters to mix the weighed raw materials evenly. The internal mixing cycle is 8 minutes, and the actual temperature of the internal mixing rubber is 100-110°C. Glue spare.

[0025] C. Roll out strips: Cut the mixed rubber into strips on the XK-550A open rubber mixing machine, park for 8-24 hours, and mak...

Embodiment 8

[0034] Example 8: A rubber needle shield for prefilled syringes, prepared from the following raw materials in parts by weight: 100 parts of synthetic polyisoprene rubber, 5-30 parts of basic white carbon black, 20-30 parts of calcined kaolin 70 parts, 0.3-1.2 parts of peroxide, 0.5-1.0 parts of stearic acid, 5-20 parts of polytetrafluoroethylene powder, 5-20 parts of ultra-high molecular weight polyethylene powder, 1-5 parts of titanium dioxide, and 0.1 parts of carbon black -3 copies.

[0035] The production steps are as follows:

[0036] A, batching: select raw material according to above-mentioned parts by weight, carry out compounding, weigh standby;

[0037] B. Internal mixing: Use a powerful pressurized internal mixer to mix the prepared raw materials evenly. The internal mixing cycle time is 5-8 minutes. The actual temperature of the internal mixing rubber is 90-110°C, and the mixed rubber is prepared for use ;

[0038] C. Opening and stripping: Cut the mixed rubber ...

Embodiment 9

[0042] Example 9: A rubber needle shield for prefilled syringes, prepared from the following raw materials in parts by weight: 100 parts of synthetic polyisoprene rubber, 10-20 parts of basic white carbon black, 40-20 parts of calcined kaolin 50 parts, peroxide 0.8-1.0 parts, stearic acid 0.7-1.0 parts, polytetrafluoroethylene powder 10-15 parts, ultra-high molecular weight polyethylene powder 10-15 parts, titanium dioxide 3-5 parts, carbon black 0.1 -1 copy.

[0043] Others are the same as embodiment 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com