High heat-resistant porous organic silicon alloy elastomer material and method for preparing same

An elastomer material and silicone technology, applied in the field of excellent porous silicone solid material and its preparation, can solve the problems of unfavorable high temperature resistance, poor water resistance, low mechanical properties, etc., and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

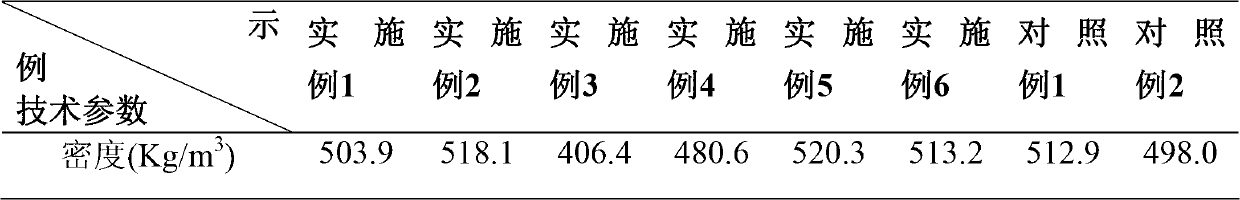

Examples

Embodiment Construction

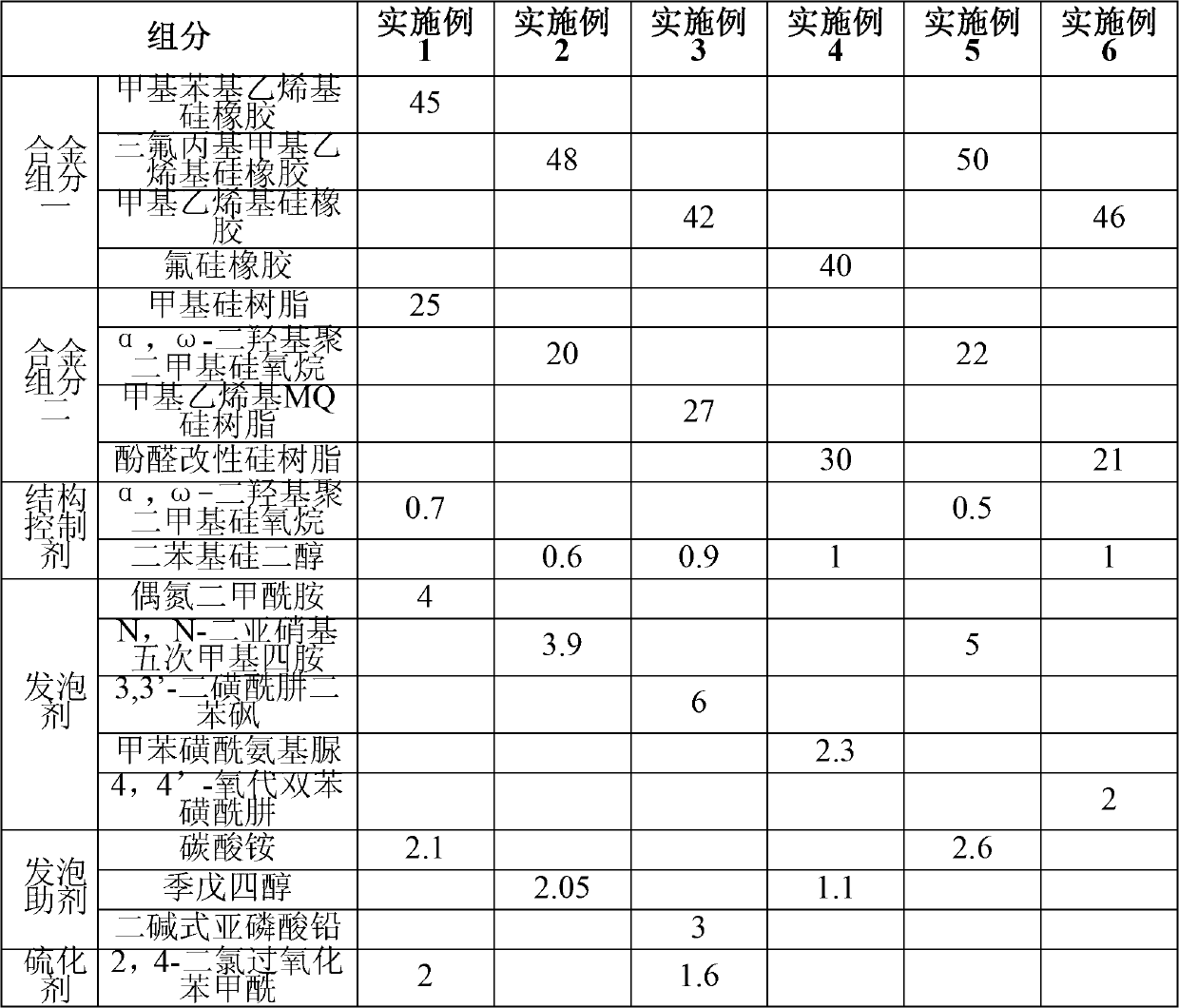

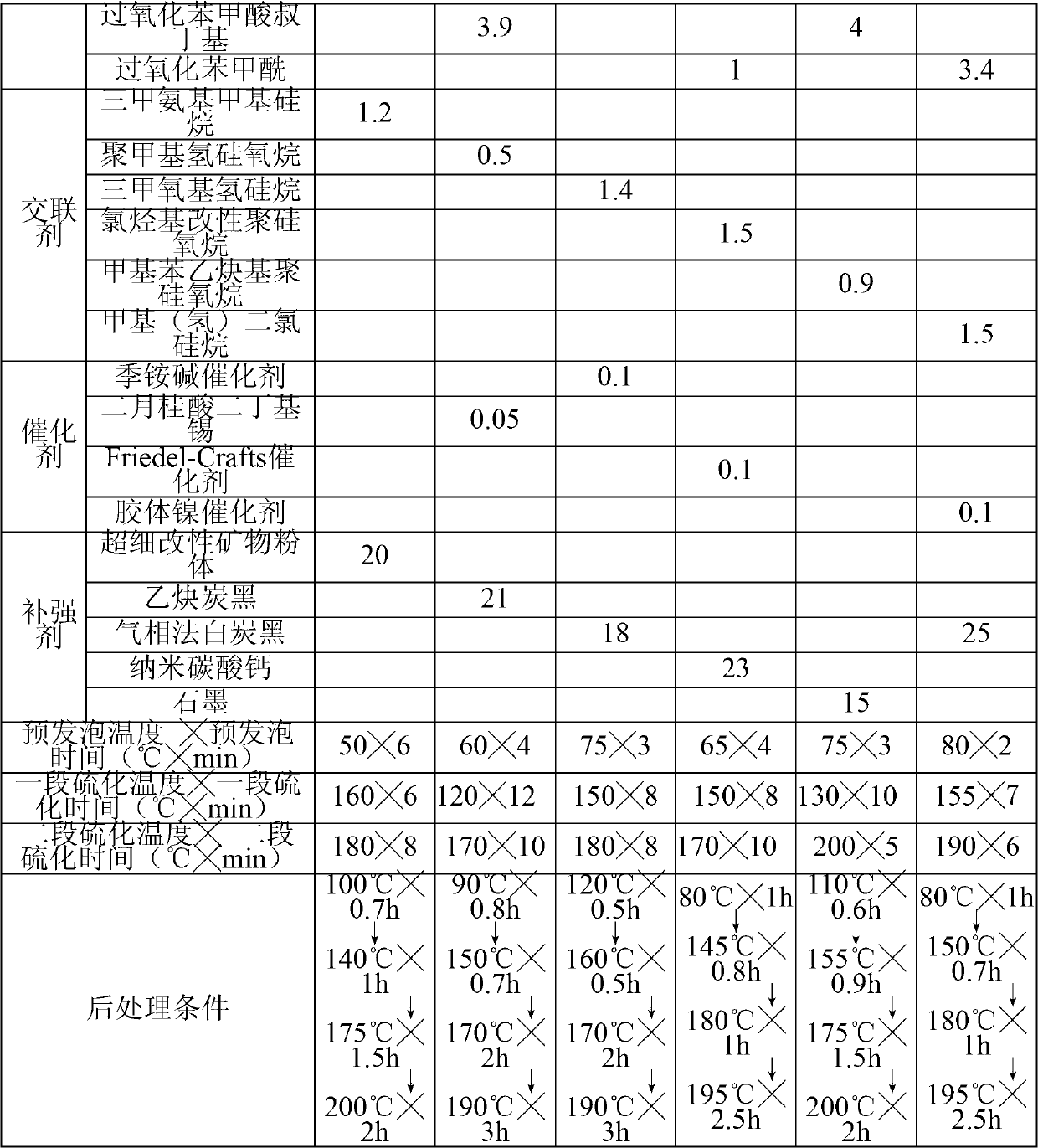

[0036] The present invention will be described in further detail below through specific examples. It should be noted that the following examples are only used to illustrate the present invention, but are not intended to limit the implementation scope of the present invention.

[0037] Unless otherwise specified, the amount of raw materials used in the present invention below are all percentages by mass.

[0038] The preparation process of the present invention is further described below in conjunction with specific implementation examples:

[0039] Weigh the mass percentage of alloy component 1, alloy component 2, crosslinking agent, structure control agent, reinforcing agent and catalyst, and use a rubber mixer to fully mix them to form a uniform mixed phase, and then mix the The refined rubber is parked for 2-4 hours; then add foaming agent, foaming aid and vulcanizing agent, and use a rubber mixer to fully mix; put the mixed rubber into the mold, and vulcanize on the press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com