Modified bamboo charcoal fiber-rubber composite sole material, preparation method and application

A bamboo charcoal fiber and composite shoe sole technology, applied in the field of materials, can solve problems such as high density and serious dust pollution in the processing process, and achieve the effects of increasing tensile strength, improving compatibility, and reducing surface polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Present embodiment adopts maleic anhydride to carry out modification to bamboo charcoal fiber according to the following steps, makes maleic anhydride modified bamboo charcoal fiber, and step comprises:

[0034] S1. Weighing: According to the weight ratio of 1:1-1:2, weigh the bamboo charcoal fiber and maleic anhydride.

[0035] S2, the preparation of modifying agent: the maleic anhydride taken in the step (S1) is completely dissolved in the DMF solvent; Simultaneously take xylene according to 6-8 times of maleic anhydride weight, and add to maleic anhydride - In the DMF solution, all the components are dissolved under stirring conditions to obtain a modifier solution.

[0036] S3, bamboo charcoal fiber modification: adding the bamboo charcoal fiber weighed in step (S1) to the modifier solution obtained in step (S2), this step is stirred and modified at 30°C, and the reaction time is 4h; Suction filtration is carried out after the reaction is finished, and the modified...

Embodiment 2

[0039] Present embodiment adopts silane coupling agent agent to carry out modification to bamboo charcoal fiber according to the following steps, makes silane coupling agent modified bamboo charcoal fiber, and step comprises:

[0040] S1. Surface passivation treatment of bamboo charcoal fibers: soak the dried bamboo charcoal fibers in a sufficient amount of NaOH solution with a mass concentration of 10% for 48 hours, take out the soaked bamboo charcoal fibers and dry them at 105°C to obtain bamboo charcoal fibers Pretreatment material.

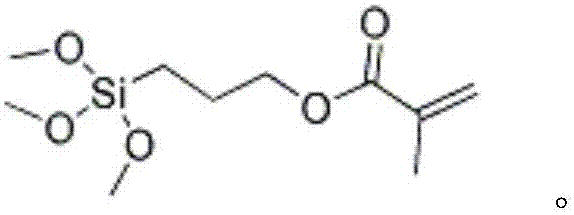

[0041] S2. Preparation of coupling modification liquid: according to the weight ratio of silane coupling agent and bamboo charcoal fiber as 1:30-1:40, weigh silane coupling agent KH570 and dissolve it in absolute ethanol, and the obtained silane coupling The concentration of the agent in absolute ethanol is 2.5%-3.5%, to obtain a coupling modified solution.

[0042] S3. Coupling modification of bamboo charcoal fiber: soak the bamboo charcoal ...

Embodiment 3

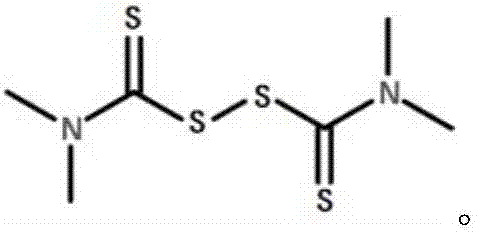

[0044] The sole material of the present embodiment is mainly formulated by the raw material of following weight portion: 30 parts of the maleic anhydride modified bamboo charcoal fiber that make with embodiment 1, other components are as follows: 50 parts of butadiene rubber, 50 parts of styrene-butadiene rubber , 30 parts of maleic anhydride modified bamboo charcoal fiber, 1.5 parts of sulfur, 3 parts of zinc oxide, 1 part of stearic acid, and 1.5 parts of accelerator TMTD.

[0045] In the preparation of the above-mentioned maleic anhydride modified bamboo charcoal fiber, the weight ratio of bamboo charcoal fiber, maleic anhydride and xylene is 1:2:14.

[0046] The preparation method of present embodiment raw material, realizes by following steps:

[0047] (1) Weighing: Weigh the above raw materials in parts by weight.

[0048] (2) Mixing: Mix the above-mentioned combined rubber weighed in the step (1) in an open mill to mix evenly. In this step, the operating parameters of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com