Loaded type high-dispersion molybdenum sulfide catalysts and preparing method thereof

A catalyst and high-dispersion technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low dispersion of active components, increase the contact surface, save active components, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

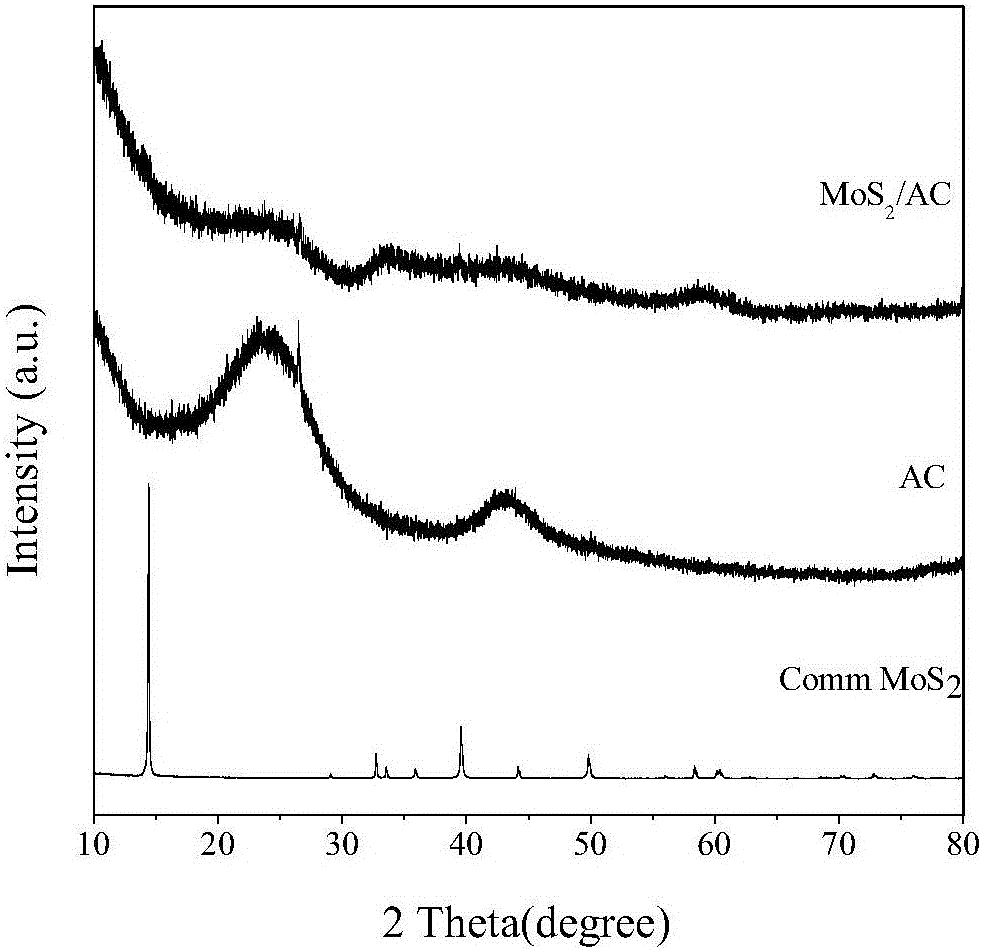

[0029] MoS 2 Preparation of / AC catalyst: Dissolve 0.92g of ammonium heptamolybdate tetrahydrate in 9mL of deionized water, add 4.5g of activated carbon after completely dissolving, impregnate at room temperature for 24h, dry in an oven at 120°C for 12h, and turn the catalyst precursor to Put it into a tube furnace, roast at 450°C for 3h under Ar atmosphere, cool to room temperature, and then perform temperature-programmed vulcanization. The specific vulcanization process is: heat up from room temperature at 5°C / min to 400°C, then keep it for 4h, and cool under Ar atmosphere to room temperature, H 2 S / H 2 The total flow rate is 60mL / min, H 2 S volume fraction of 10% yielded MoS with 10 wt% Mo loading 2 / AC Catalyst.

Embodiment 2

[0031] MoS 2 Preparation of / AC catalyst: The preparation process is similar to Example 1, the difference is that the loading of Mo is changed to 2wt%, and MoS with a loading of Mo of 2wt% is obtained 2 / AC Catalyst.

Embodiment 3

[0033] MoS 2 Preparation of / AC catalyst: The preparation process is similar to Example 1, the difference is that the loading of Mo is changed to 30wt%, and MoS with a loading of Mo of 30wt% is obtained 2 / AC Catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com