Method for preparing open-cell ZIF-8/polymer composite foam material by using solid-phase shearing and milling technology

A solid phase shear milling, ZIF-8 technology, applied in the field of biomedical materials, can solve the problems of unfavorable regular distribution of cells, affecting the uniformity of cell distribution, etc., to achieve uniform cell size and distribution, low cost, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for preparing open-cell ZIF-8 / polymer composite foam material by solid phase shear milling technology, comprising the following steps in parts by weight:

[0049] (1) After mixing 40 parts of PVDF pellets and 60 parts of NaCl particles in total to 100 parts, they are added to a disc-type mechanochemical reactor for grinding and pulverization. After the grinding is completed, the PVDF / NaCl mixed powder is collected; among them, the disc-type The process parameters of the mechanochemical reactor are: the grinding pressure is 10 MPa, the surface temperature of the grinding disc is controlled by feeding a constant temperature circulating liquid medium with a temperature of 15 °C, the rotating speed of the grinding disc is 50 rpm, and the grinding cycle is 10 times;

[0050] (2) The PVDF / NaCl mixed powder obtained in step (1) is prepared into a block through a hot pressing molding process, and the block is immersed in deionized water until NaCl is completely dissolve...

Embodiment 2

[0058]A method for preparing open-cell ZIF-8 / polymer composite foam material by solid phase shear milling technology, comprising the following steps in parts by weight:

[0059] (1) After mixing 50 parts of PVDF pellets and 50 parts of NaCl particles in total to 100 parts, they are added to a disc-type mechanochemical reactor for grinding and pulverization. After the grinding is completed, the PVDF / NaCl mixed powder is collected; among them, the disc-type The process parameters of the mechanochemical reactor are: the grinding pressure is 10 MPa, the surface temperature of the grinding disc is controlled by feeding a constant temperature circulating liquid medium with a temperature of 15 °C, the rotating speed of the grinding disc is 50 rpm, and the grinding cycle is 10 times;

[0060] (2) The PVDF / NaCl mixed powder obtained in step (1) is prepared into a block through a hot pressing molding process, and the block is immersed in deionized water until NaCl is completely dissolved...

Embodiment 3

[0067] A method for preparing open-cell ZIF-8 / polymer composite foam material by solid phase shear milling technology, comprising the following steps in parts by weight:

[0068] (1) After mixing 60 parts of PVDF pellets and 40 parts of NaCl particles in total to 100 parts, they are added to a disc-type mechanochemical reactor for grinding and pulverization. After the grinding is completed, the PVDF / NaCl mixed powder is collected; among them, the disc-type The process parameters of the mechanochemical reactor are: the grinding pressure is 10 MPa, the surface temperature of the grinding disc is controlled by feeding a constant temperature circulating liquid medium with a temperature of 15 °C, the rotating speed of the grinding disc is 50 rpm, and the grinding cycle is 10 times;

[0069] (2) The PVDF / NaCl mixed powder obtained in step (1) is prepared into a block through a hot pressing molding process, and the block is immersed in deionized water until NaCl is completely dissolve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

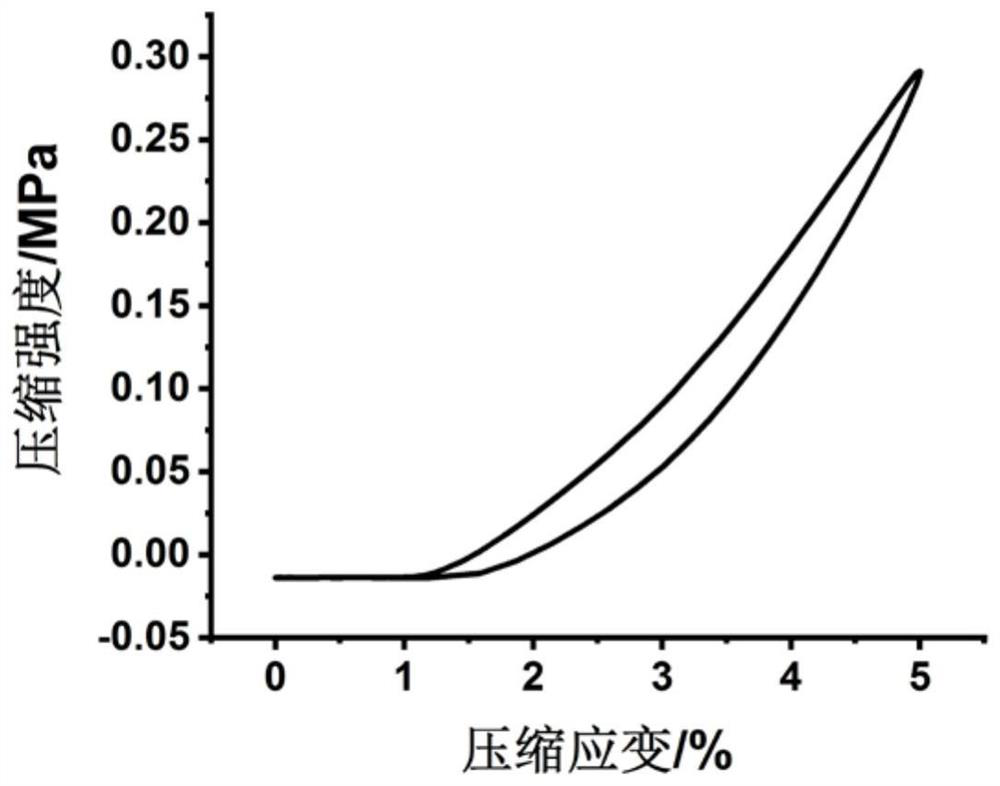

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com