Low-thermal-conductivity polyimide foam material and preparation method thereof

A technology of polyimide and foam materials, which is applied in the field of low thermal conductivity polyimide foam materials and its preparation, can solve the problems of low imidization degree, complex process, and many foam defects, and achieve shape integrity Good, simple process operation, low thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

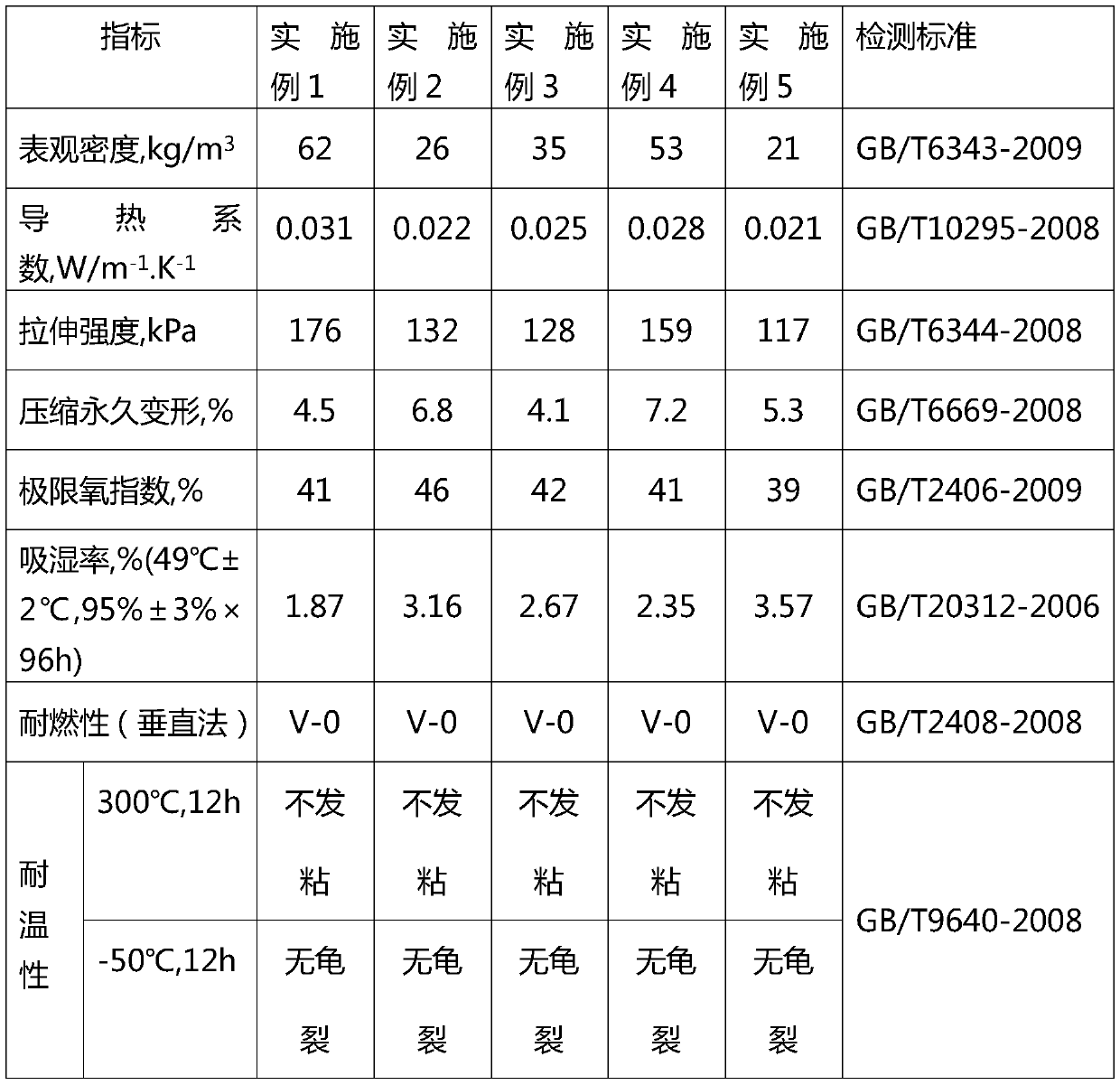

Examples

Embodiment 1

[0039] 1) Add 90g of 3,3`,4,4`-biphenyltetracarboxylic dianhydride into a reaction kettle filled with 120g of tetrahydrofuran, stir at 105°C for 30min to fully dissolve the dianhydride, the stirring method is magnetic stirring, stirring The speed is 400r / min to prepare the dianhydride solution; slowly add 20g of methanol into the dianhydride solution, keep the temperature at 60°C and stir for 1h to generate the precursor esterification solution. The stirring method is magnetic stirring, and the stirring speed is 550r / min;

[0040] 2) After the precursor esterification solution was lowered to room temperature, a catalyst composed of 0.8 g of stannous octoate, 0.8 g of triethanolamine, 1.1 g of tetramethylethylenediamine, 3.3 g of water and 2.5 g of p-toluenesulfonamidourea The composite foaming agent, 9.0g DC5950, and 8.6g polyethylene glycol 400 were sequentially added to the precursor esterification solution, and stirred for 10 minutes to make it evenly mixed to obtain a foa...

Embodiment 2

[0044] 1) Add 135g of pyromellitic dianhydride into a reaction kettle containing 160g of N,N-dimethylformamide, stir at 90°C for 45 minutes to fully dissolve the dianhydride, and prepare a dianhydride solution. The stirring method is magnetic Stir at a stirring rate of 1100r / min; slowly add 38g of propanol to the dianhydride solution, keep the temperature at 72°C and stir for 0.8h to generate a precursor esterification solution. The stirring method is magnetic stirring at a stirring rate of 660r / min. min;

[0045] 2) After the precursor esterification liquid is lowered to room temperature, a composite catalyst composed of 1.1g dibutyltin dilaurate, 1.2g pentamethyldiethylenetriamine, 0.8g triethylenediamine, 7.8g magnesium carbonate, The composite blowing agent composed of 6.9g n-hexane, 6.2g Span-60, 5.8g AK8803, and 8.6g polyethylene glycol 1000 were sequentially added to the precursor esterification solution, and stirred for 15 minutes to make it evenly mixed to obtain foam...

Embodiment 3

[0049] 1) Add 120g of 3,3`,4,4`-benzophenonetetracarboxylic dianhydride into a reaction kettle filled with 135g of dichloromethane, stir at 125°C for 25min to fully dissolve the dianhydride, and obtain di Anhydride solution, the stirring method is magnetic stirring, and the stirring rate is 800r / min; slowly add 36g of ethylene glycol into the dianhydride solution, keep the temperature at 82°C and stir for 1.5h to form a precursor esterification solution, the stirring method is Magnetic stirring, the stirring rate is 710r / min;

[0050] 2) After the precursor esterification solution was lowered to room temperature, 4.6g Triton x-100, 6.8g AK8805, 10.2g polyethylene glycol 600, composed of 4.5g petroleum ether and 7.8g dioxane were sequentially added to it Composite foaming agent, composite catalyst composed of 0.8g bismuth laurate, 0.6g triethylenediamine, 2.1g triethylenediamine, and stirred for 1h to make it mix uniformly to obtain foaming white material, the stirring method i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com