Tread rubber material for snow tire

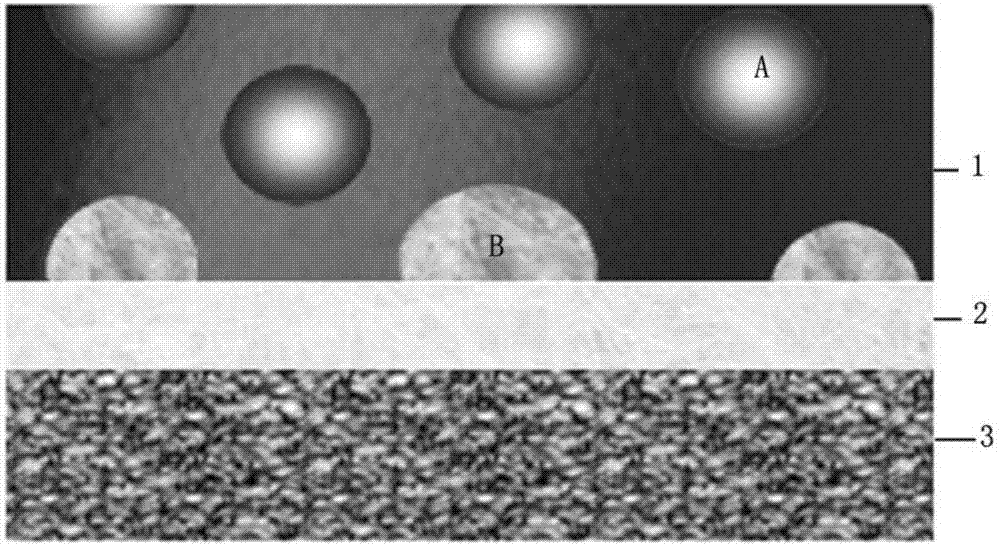

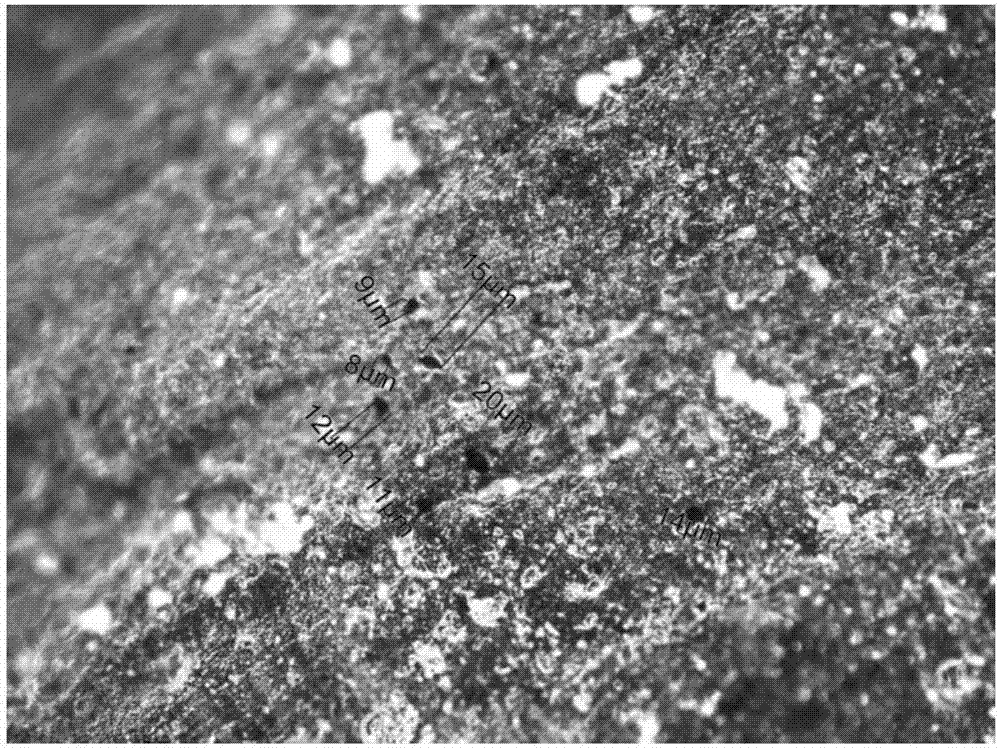

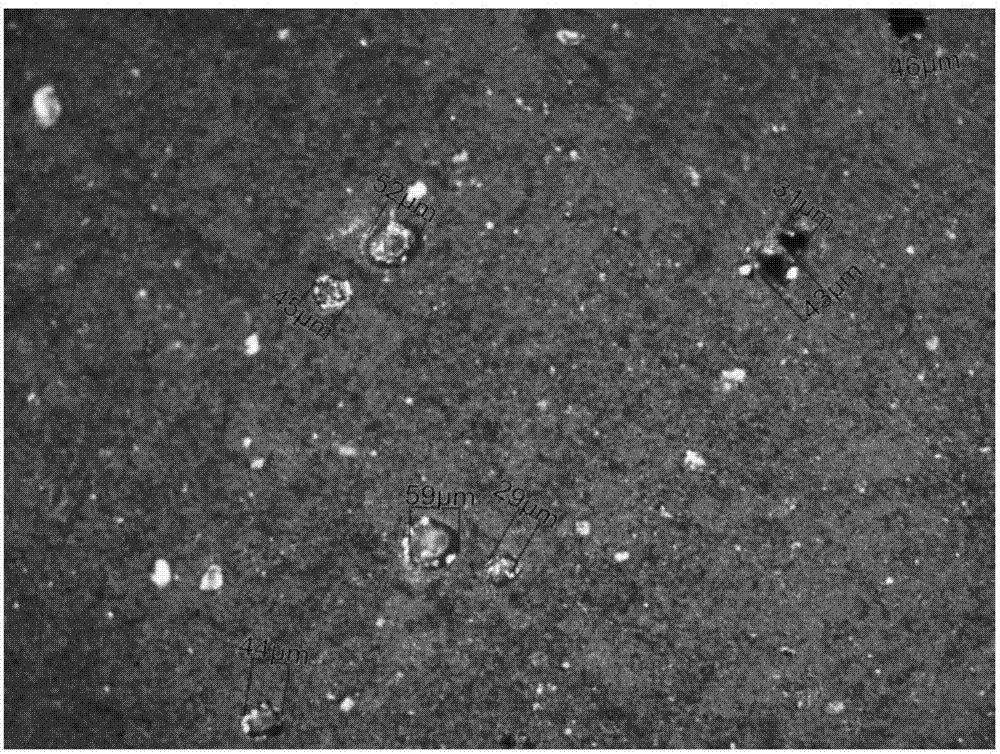

A technology for tread rubber and snow tires, applied in the field of snow tire tread compounds, can solve the problems of poor ice-skid resistance, poor surface cells, uneven foaming, etc., and achieves good thermal stability and processing. Improved safety, cell size and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0058] The formula of table 1 embodiment 1-3 and comparative example 1

[0059]

[0060]

[0061] Among them, the chemical foaming agent is Chemmix OBSH-75 produced by Shanghai Jingyi Rubber Technology Co., Ltd., the total sulfur content is 12.0-14.0%, and the density at 20°C is 1.20-1.30g / cm 3 , Gas generation at 20°C ≥ 95.0ml / g, Mooney viscosity ML(1+4) 40-70 at 50°C.

[0062] The preparation technology of embodiment 1-3:

[0063] (1) One stage of rubber mixing: mixing is carried out in a Banbury internal mixer, adding raw rubber, zinc oxide, stearic acid, and 50 parts of carbon black, pressing the top bolt and mixing for 25 seconds, then raising the top bolt , add the remaining carbon black, rubber operating oil, anti-aging agent RD, anti-aging agent 4020, protective wax, press the top bolt, knead for 30 seconds, lift the top bolt to clean, press the top bolt and knead for 25 seconds, raise the top bolt Cleaning, pressing the top bolt and mixing for 25 seconds, open...

Embodiment 4-6

[0069]The formula of table 2 embodiment 4-6 and comparative example 2

[0070]

[0071] Remarks: The ordinary white carbon black described in the examples is JINSIL 700 produced by Jinneng Technology Co., Ltd., and the nitrogen adsorption specific surface area is 178m 2 / g; Low surface area and highly dispersed silica is 822MP produced by Wuxi Hengcheng Silicon Industry Co., Ltd., and the nitrogen adsorption specific surface area is 118m 2 / g; High specific surface area and highly dispersed silica is Ultrasil 9000GR produced by Evonik, with a nitrogen adsorption specific surface area of 235m 2 / g.

[0072] Embodiment 4-6 preparation technology:

[0073] (1) One-stage master batch: adjust the speed of the meshing mixer to 55r / min, add raw rubber, 1 / 2 white carbon black, 3 / 4 parts of sulfur-containing organosilicon compounds, and guanidine accelerators, and press on the top The bolt is mixed for 35s; raise the top bolt, add 1 / 4 white carbon black, 3 / 4 rubber operating oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Gas output | aaaaa | aaaaa |

| Nitrogen adsorption specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com