Torsion beam suspension

A torsion beam suspension and torsion beam technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve problems such as difficult control, increase trunk space, and difficult to control lateral flexibility, and achieve overall Improved dynamics, improved handling stability and comfort, reduced wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

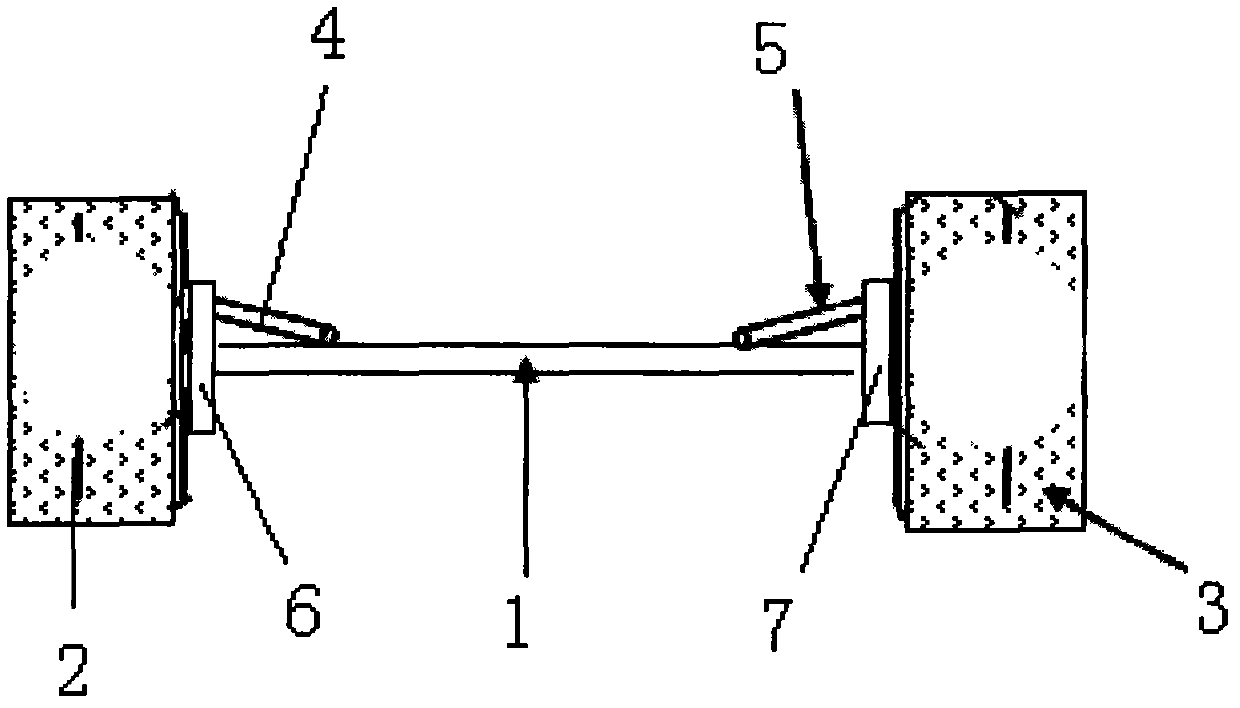

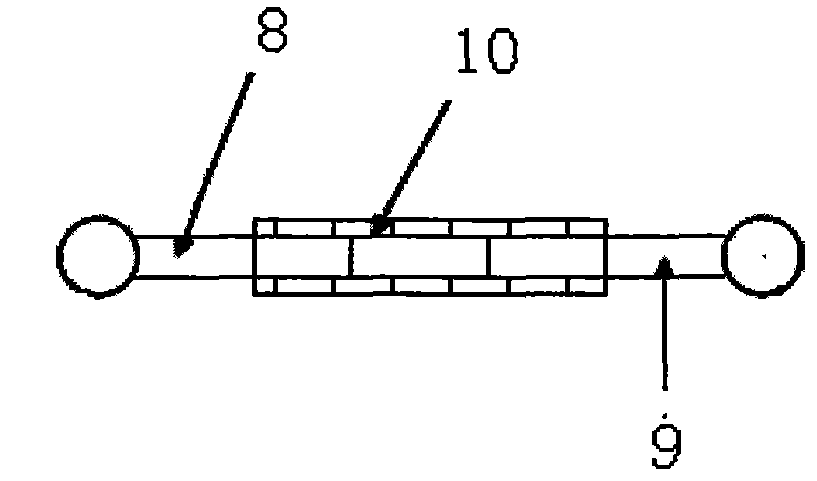

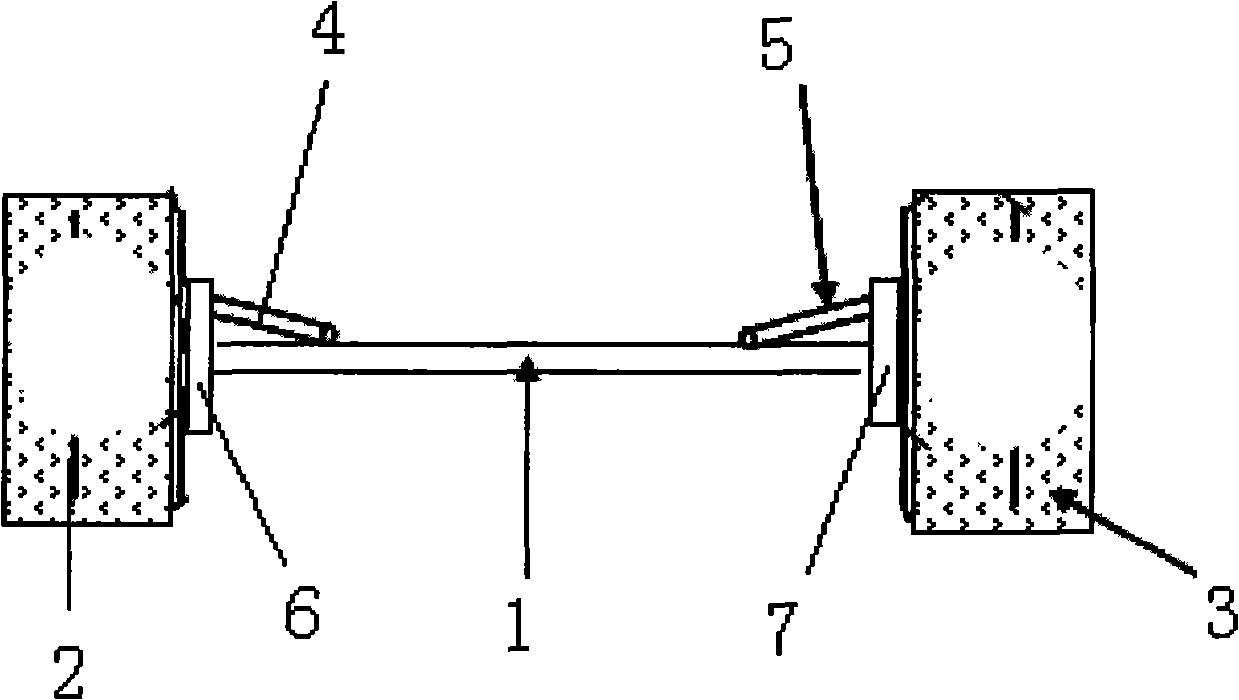

[0018] Such as figure 1 As shown, the torsion beam suspension of this embodiment includes a pair of suspensions distributed on the left and right sides of the vehicle and extending along the front and rear directions of the vehicle. 1. The right suspension trailing arm and the torsion beam 1 extending along the width direction of the vehicle, the two ends in the length direction are respectively connected to the left and right suspension trailing arms, and the length-adjustable left adjustment rod 4 is symmetrically installed on the torsion beam 1. Right adjustment rod 5, one end of the left adjustment rod 4 is fixedly connected with the torsion beam 1, and the other end is connected with the top of the steering knuckle 6 of the wheel 2 on the same side; one end of the right adjustment rod 5 is fixedly connected with the torsion beam 1, The other end is connected with the top of the steering knuckle 7 of the same side wheel 3 (the left and right suspension trailing arms are no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com