Hydrodynamic transmission used for hydrodynamic forklift and provided with pump mechanism

A hydraulic transmission and hydraulic technology, applied in the field of transmissions for 2-3.5t hydraulic forklift trucks, can solve the problems of separate removal of the transmission and the transmission without a working pump, so as to improve the operating comfort and reduce the vibration of the whole vehicle. , the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

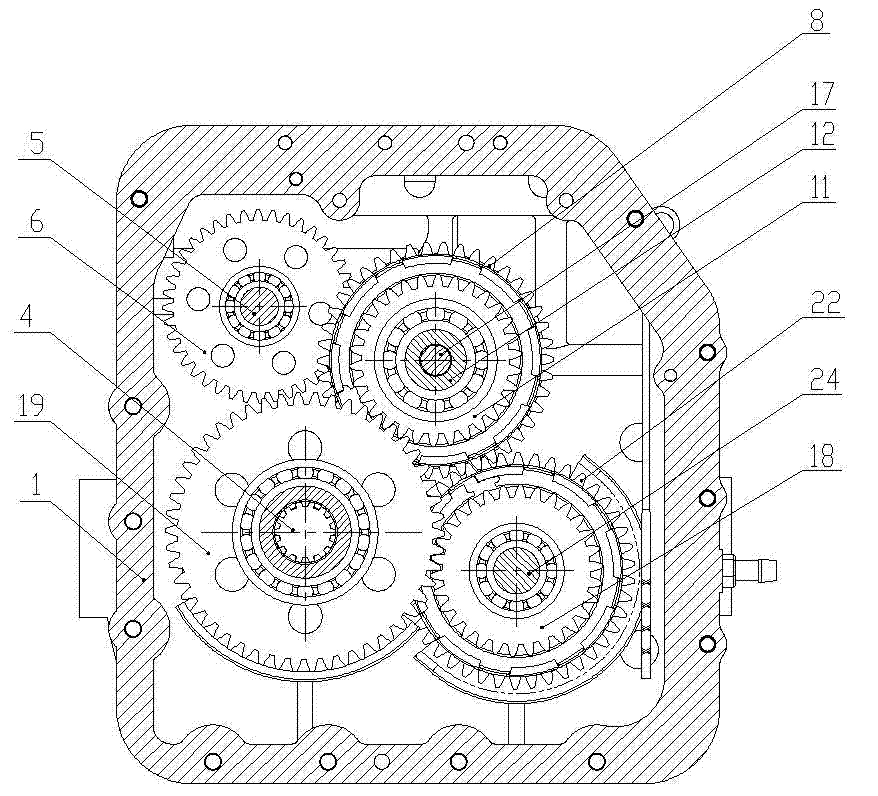

[0028] see figure 1 The hydraulic transmission for a hydraulic forklift with a pump mechanism includes a transmission case 1, the upper side of the case 1 is equipped with a lubricating pump drive shaft 5 through a bearing, and one end of the lubricating pump drive shaft 5 extends to the outside of the case 1, A lubricating pump 2 is installed on the extended end of the lubricating pump transmission shaft 5, and a first lubricating pump transmission gear 6 is fixedly installed on the lubricating pump transmission shaft 5;

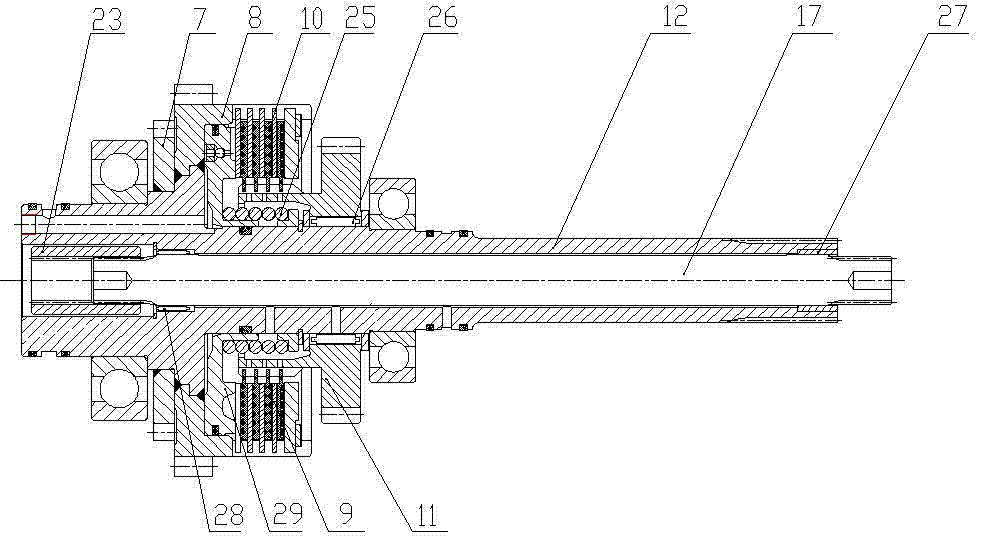

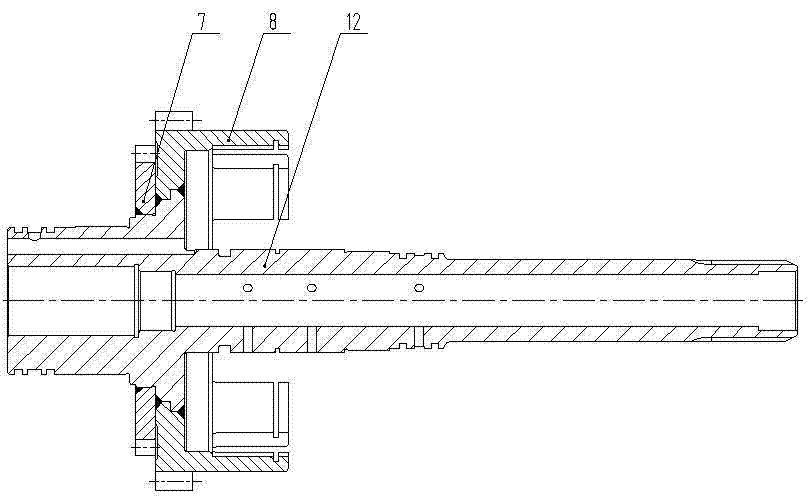

[0029] see figure 2 , The other side of the upper part of the casing 1 is equipped with a working pump transmission shaft tube 12 through a bearing. see figure 1 On one side of the working pump transmission shaft tube 12, the front casing of the second lubricating pump transmission gear 7 and the forward gear clutch 10 are welded in sequence, and the forward gear 11 is installed through the first needle bearing 26, and the forward gear 10 The outer side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com