Shift shaft assembly pulling head position accuracy testing fixture

A technology of position degree and shift shaft, which is applied in the direction of measuring device, mechanical device, mechanical measuring device, etc., can solve the problems of large jitter of the control cover and out-of-tolerance position, and achieve the effect of avoiding jitter and improving the comfort of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

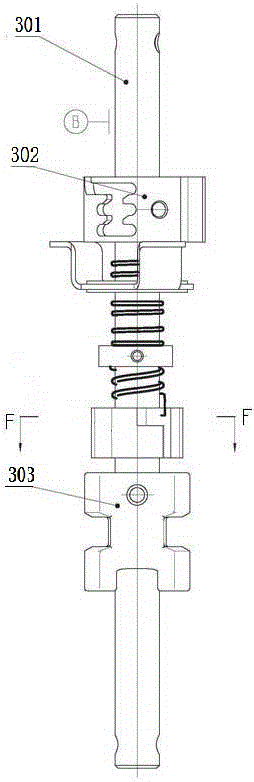

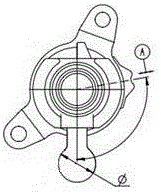

[0018] like figure 1 and figure 2 The shown shift shaft assembly has a fork shaft 301, on which a shift head 303 and a shift cam 302 are respectively set, and the top of the shift cam 302 is provided with an arc-shaped groove ; Take the center of the arc groove at the top of the cam and the center line of the fork shaft 301 as the reference A, take the outer diameter of the fork shaft 301 as the reference B, and the diameter φ of the shifting head 303 is to the degree of the reference A and the reference B position The maximum inclusion is 0.3.

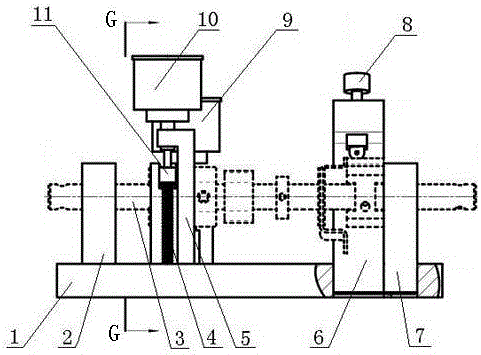

[0019] like image 3 , Figure 4 and Figure 5 The shown gear shift shaft assembly shift head position inspection tool includes a base plate 1, on which two V-shaped positioning blocks are installed, and the two V-shaped positioning blocks are respectively V-shaped positioning block 2 and V-shaped positioning block 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com