Process for creating a foam utilizing an antimicrobial starch within a process for manufacturing a paper or board product

An anti-microbial and foam technology, applied in paper making, paper machine, foam addition, etc., can solve problems such as poor strength properties, microbial contamination quality, deterioration, etc., achieve good retention, uniform bubble size, reduce microbial contamination and quality. The effect of the risk of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1. Foam coating in sizing press

[0049] The test was carried out on a test paper machine. The productivity on the test paper machine is 45m / min, and the base plate weight is 130g / m 2 . In addition to CTMP pulp, cationic starch (6.0kg / tn), alkyl succinic anhydride, ASA (700g / tn), alum (600g / t) and two-component retention system (100g / tn cationic polypropylene Amide and 300g / tn silica). The paper web uses starch (Raisamyl 21221) or antibacterial starch on the sizing press unit on-line surface sizing. For Raisamyl 21221 and antimicrobial starch, the surface sizing absorption is 0.64g / m respectively 2 And 0.95g / m 2 . The paper is dried to a final moisture content of 8%, rolled and cut into pieces.

[0050] As a reference sample, 5% solids sized pressed starch Raisamyl 21221 was used. In the reference sample, foaming starch and surfactants were not used. Measure the surface energy (two-liquid method) of the top surface and find it to be 24.4mJ / m 2 . When PE is coa...

Embodiment 2

[0052] Example 2. Foaming

[0053] Compare the foaming tendency of antibacterial starch with conventional cationic wet end starch (Raisamyl 50021). The two starches were cooked and diluted to 1% consistency, and then mixed with a mixer at a propeller speed of 6000 rpm for 15 minutes. The amount of sample in the mixing is 300 ml.

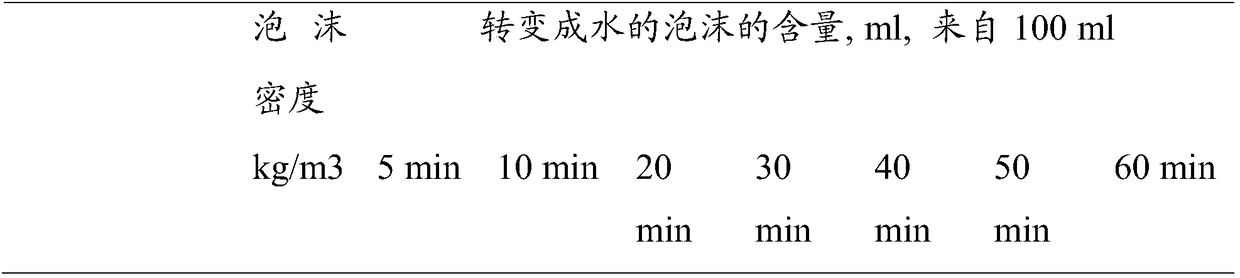

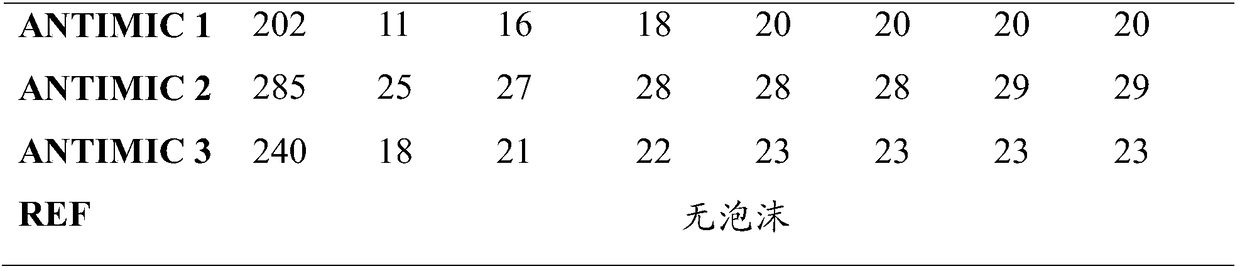

[0054] For antimicrobial starch, the foam content of the foam converted into water is used as a function of time to study the stability of the foam phase. For this measurement, 100 ml of foam is taken into a beaker, and the content of the water phase is measured after several time intervals. The results of 3 parallel mixed batches of antimicrobial starch (ANTIMIC) and 1 mixed batch of conventional cationic wet end starch (REF) are listed in Table 1.

[0055] Table 1. The content of foam (ML) converted to water as a function of time.

[0056]

[0057]

[0058] In addition, the antibacterial starch and the conventional cationic wet end starch as the foaming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com