Full biodegradable heat-resistant polylactic acid foaming material and preparation method thereof

A polylactic acid foaming and all-biological technology, which is applied in the field of fully biodegradable heat-resistant polylactic acid foaming materials and its preparation, can solve problems in the experimental stage, large foam size, complex molding process, etc., to overcome size unevenness , Uniform cell size, overcome the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

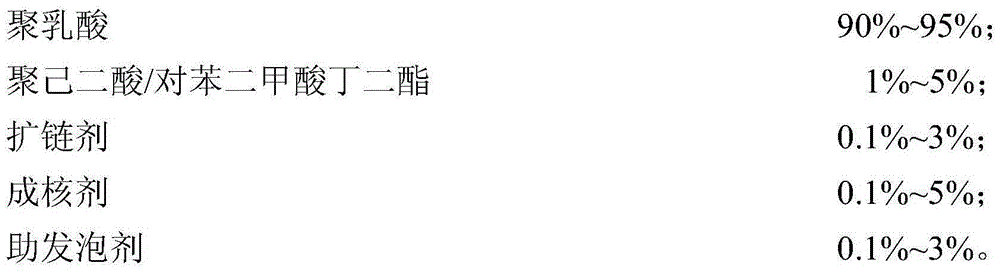

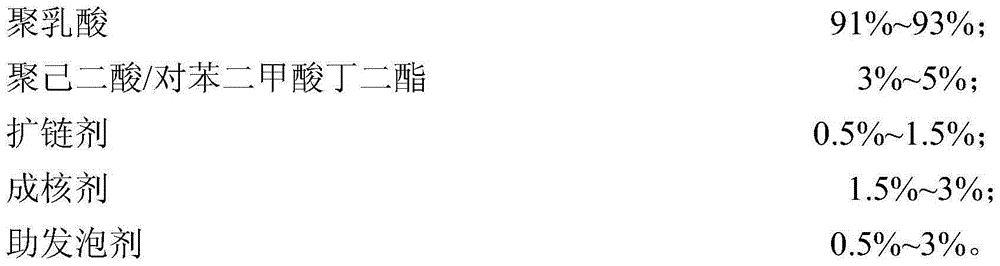

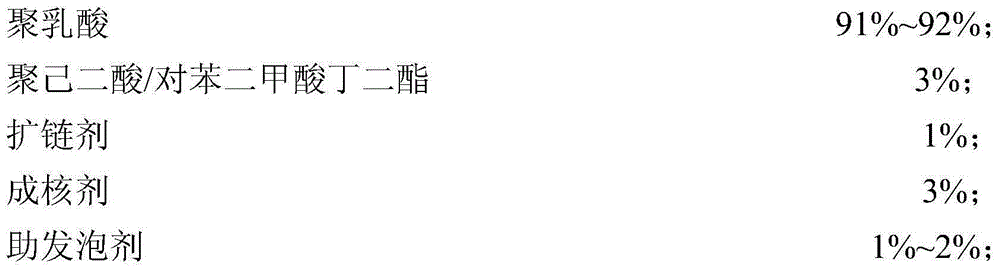

[0032] Weigh the following ingredients by weight:

[0033] Polylactic acid (4032D of American Natureworks) 92.5Kg, PBAT resin (Biocosafe2003, Yifan Xinfu Pharmaceutical Co., Ltd.) 3Kg, chain extender (ADR4370, BASF AG) 1Kg, nucleating agent (EBH, Suzhou Liansheng Chemical Co., Ltd.) Co., Ltd., 1kg; talcum powder, 5000 mesh, Dandong Tianci Flame Retardant Material Technology Co., Ltd., 2kg), foaming agent (polyoxyethylene sorbitan fatty acid ester T-80, Shanghai Yanwang Industrial Co., Ltd.) 0.5 kg.

[0034] The preparation method of heat-resistant polylactic acid foam material:

[0035] First, add polylactic acid to a high-speed mixing dryer, dry at 105°C for 30 minutes, add other additives after cooling and mix evenly; then put the mixed material into a twin-screw extruder for melt blending (screw temperature is 170°C -180°C) and then stretched, air-cooled, and pelletized to obtain a fully biodegradable heat-resistant polylactic acid foam material. The selected twin-screw ...

Embodiment 2

[0037] Weigh the following ingredients by weight:

[0038] Polylactic acid (4032D of American Natureworks) 90.5Kg, PBAT resin (Biocosafe2003, Yifan Xinfu Pharmaceutical Co., Ltd.) 5Kg, chain extender (ADR4370, BASF AG) 1.5Kg, nucleating agent (EBH, Suzhou Liansheng Chemical Co., Ltd., 1kg; talcum powder, 5000 mesh, Dandong Tianci Flame Retardant Material Technology Co., Ltd., 1kg), foaming aid (polyoxyethylene sorbitan fatty acid ester T-80, Shanghai Yanwang Industrial Co., Ltd.) 1kg.

[0039] The preparation method is as described in Example 1.

Embodiment 3

[0041] Weigh the following ingredients by weight:

[0042] Polylactic acid (4032D of American Natureworks) 91Kg, PBAT resin (Biocosafe2003, Yifan Xinfu Pharmaceutical Co., Ltd.) 4Kg, chain extender (ADR4370, BASF AG) 0.5Kg, nucleating agent (EBH, Suzhou Liansheng Chemical Co., Ltd.) Co., Ltd., 0.5kg; talcum powder, 5000 mesh, Dandong Tianci Flame Retardant Material Technology Co., Ltd., 1kg), foaming aid (polyoxyethylene sorbitan fatty acid ester T-80, Shanghai Yanwang Industrial Co., Ltd.) 3kg.

[0043] The preparation method is as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com