Polylactide-based blended material, preparation method thereof and method for preparing foam material from polylactide-based blended material

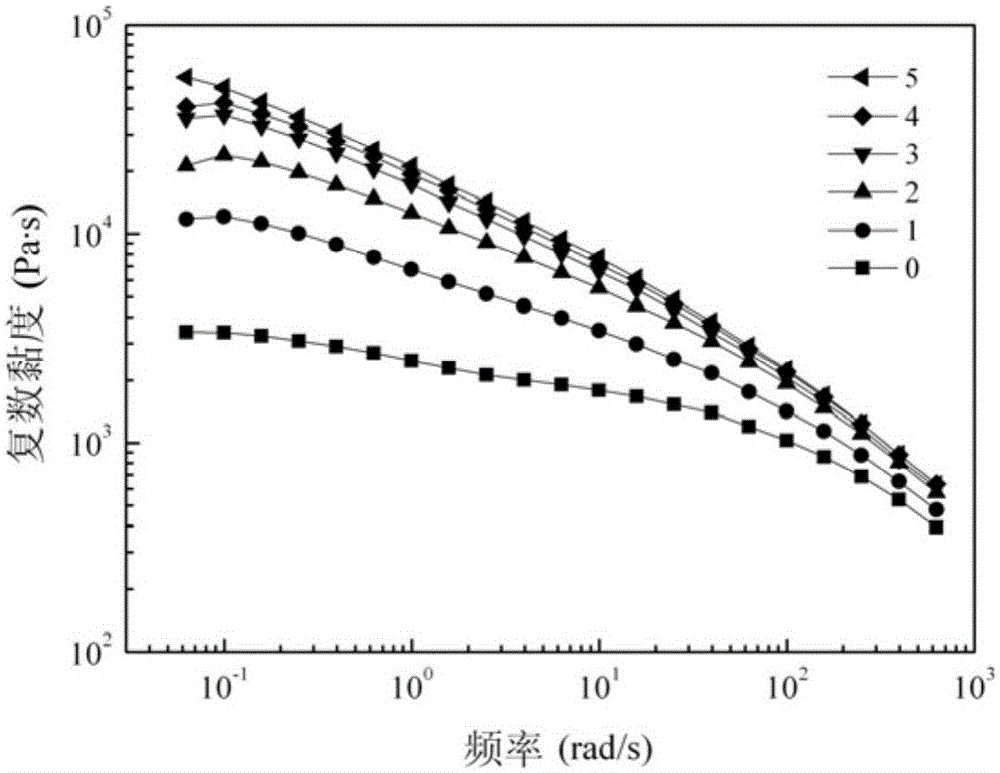

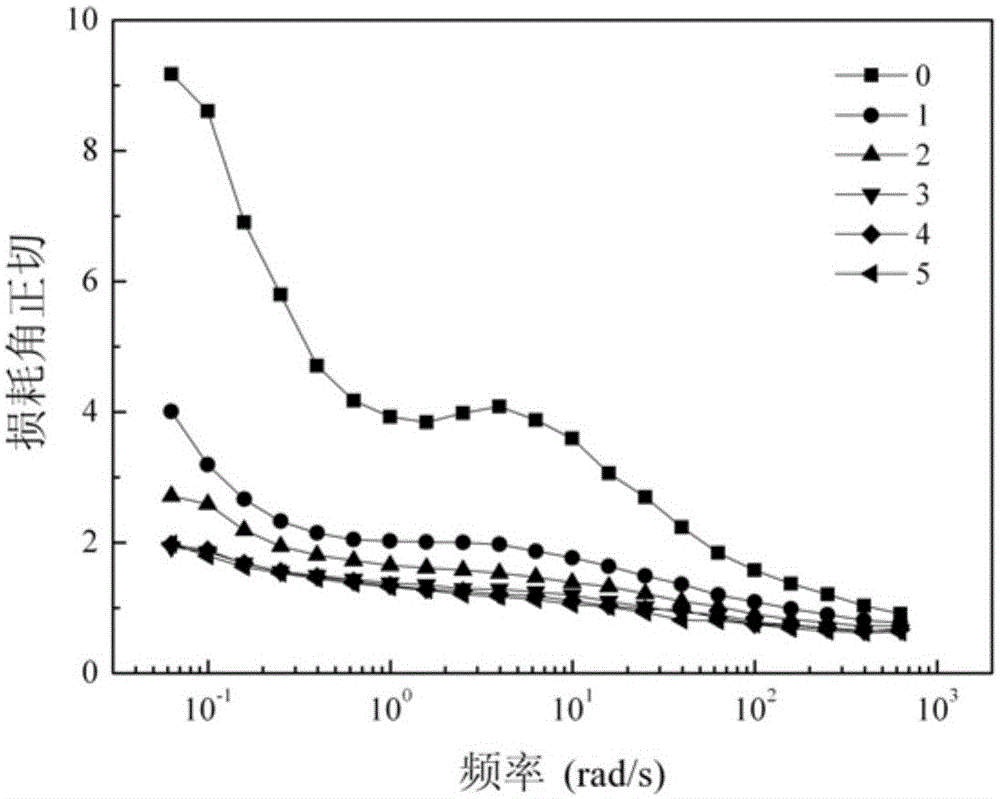

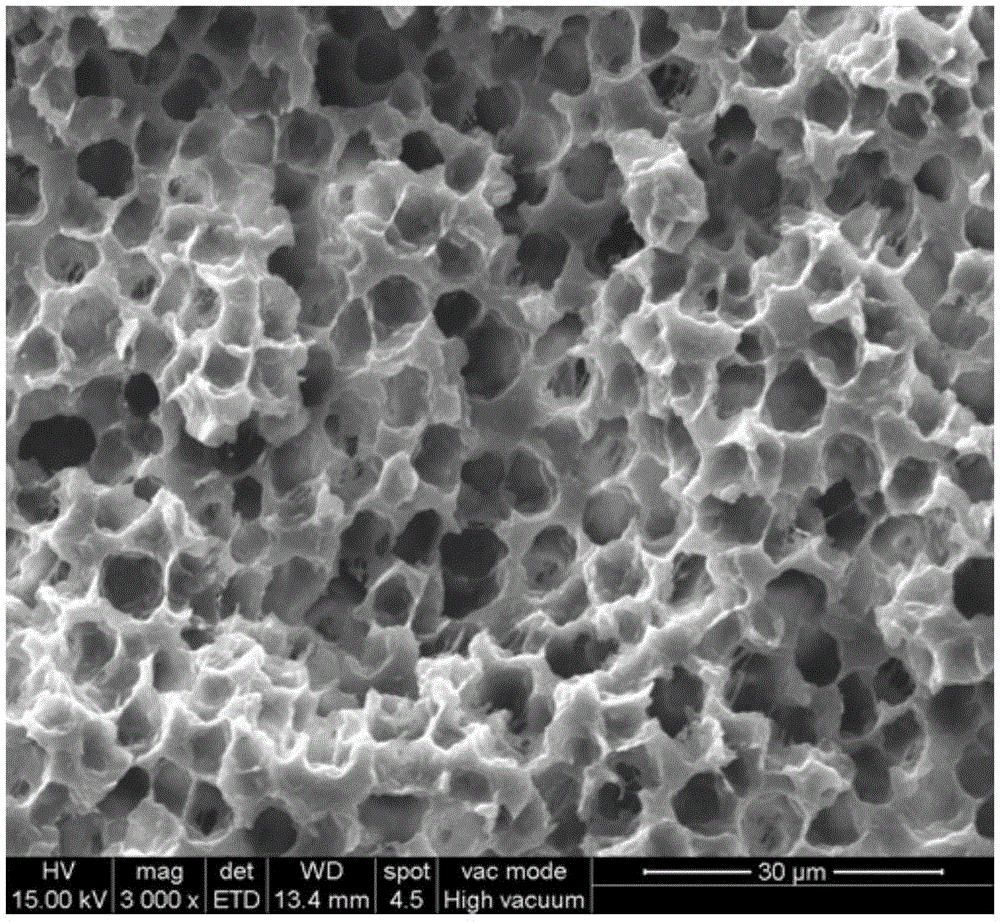

A technology of polylactic acid-based and foamed materials, which is applied in the field of polylactic acid-based blended materials and its preparation, can solve the problem of incomplete biodegradation of foamed PLA materials, difficulty in controlling cell structure and size, and residual chemical foaming agents, etc. problem, to achieve the effect of easy control of cell density, high reproducibility and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] PLA and TPU with a mass ratio of 80:20 and Joncryl with a mass content of 0.25% were mechanically mixed, and then the premix was added to a chaotic mixing type extruder for melt reaction blending to prepare PLA / TPU reactive blends. mix materials. The screw speed of the extruder is 40r / min, and the barrel temperature is 150-190°C.

[0053] The test results: the impact strength, tensile strength and elongation at break of the PLA / TPU reactive blend material are 69.2kJ / m 2 , 36.5MPa and 272.6%.

Embodiment 2

[0055] PLA and TPU with a mass ratio of 80:20 and Joncryl with a mass content of 0.5% were mechanically mixed, and then the premix was added to a chaotic mixing type extruder for melt reaction blending to prepare PLA / TPU reactive blends. mix materials. The screw speed of the extruder is 40r / min, and the barrel temperature is 150-190°C.

[0056] The test results: the impact strength, tensile strength and elongation at break of the PLA / TPU reactive blend material are 73.5kJ / m 2 , 38.0MPa and 375.4%.

Embodiment 3

[0058] PLA and TPU with a mass ratio of 80:20 and Joncryl with a mass content of 0.75% were mechanically mixed, and then the premix was added to a chaotic mixing extruder for melt reaction blending to prepare PLA / TPU reactive blends. mix materials. The screw speed of the extruder is 40r / min, and the barrel temperature is 150-190°C.

[0059] The test results: the impact strength, tensile strength and elongation at break of the PLA / TPU reactive blend material are 78.3kJ / m respectively 2 , 38.5MPa and 376.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com