Composite toughening modifier for plastics and preparation method thereof

A technology for toughening modifiers and plastics, which can be used in the treatment of fibrous fillers and dyed polymer organic compounds. Plasticizing ability, toughening effect, impact strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Based on 100 parts of total monomer mass, add 2.5 parts of alkylphenol polyoxyethylene ether (OP-10) and 0.5 part of sodium dodecylbenzenesulfonate into the reaction kettle, add 200 parts of water, mix and heat up to At 65°C, add 15 parts of n-butyl acrylate, after pre-emulsification, add 0.15 parts of ammonium persulfate to initiate polymerization, keep the reaction at 75°C for 20 minutes, and obtain polyacrylate soft monomer seed emulsion;

[0049] Add 15 parts of n-butyl acrylate, 15 parts of n-octyl methacrylate, and 55 parts of methyl methacrylate dropwise in sequence at 78°C to the seed emulsion to continue the reaction, adding 0.1 part of ammonium persulfate during the reaction for 2.5 hours; After dropping the monomers, add 0.1 part of ammonium persulfate, keep warm for 4.5 hours, then cool and discharge to obtain polyacrylate elastomer emulsion P1.

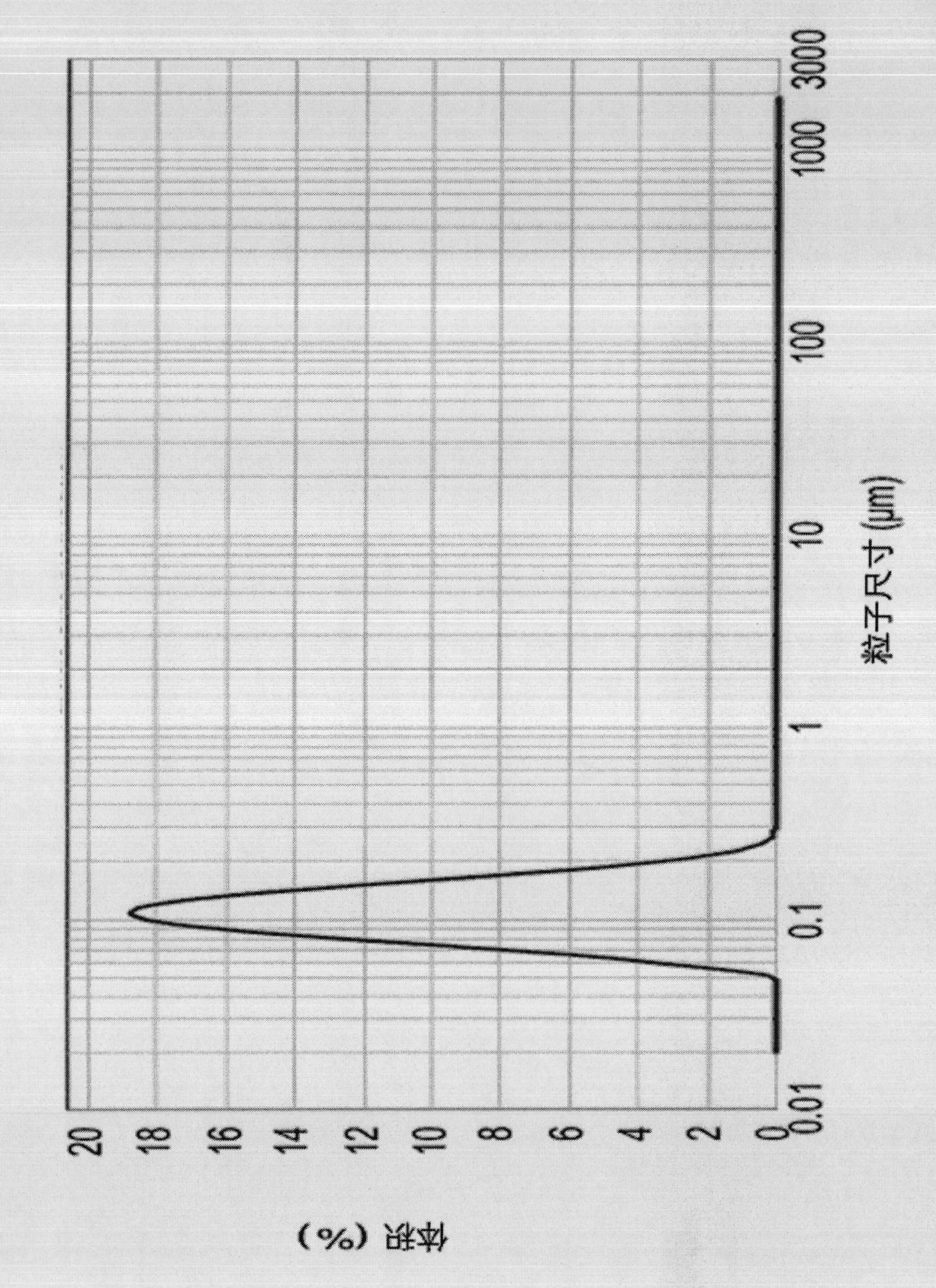

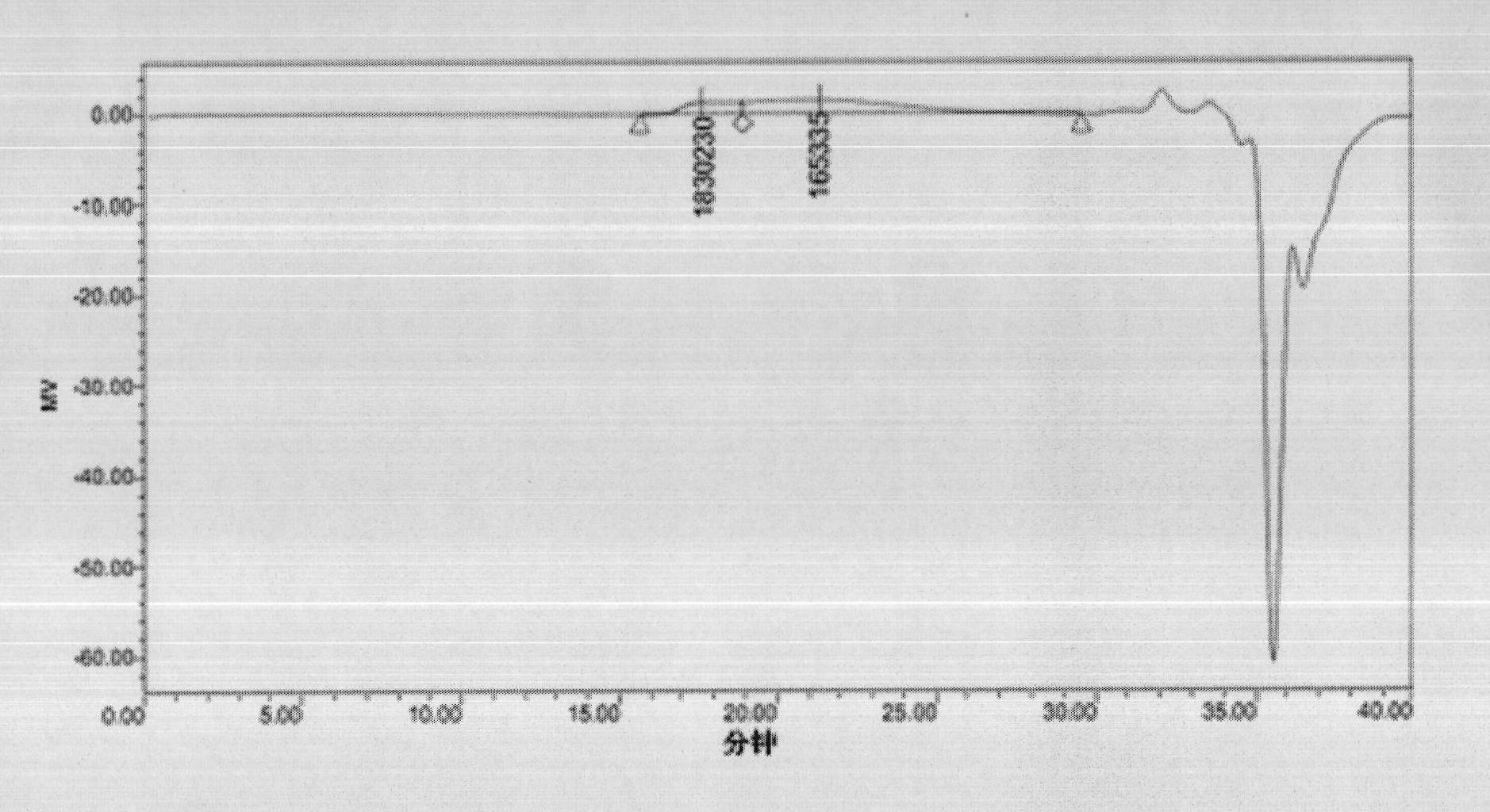

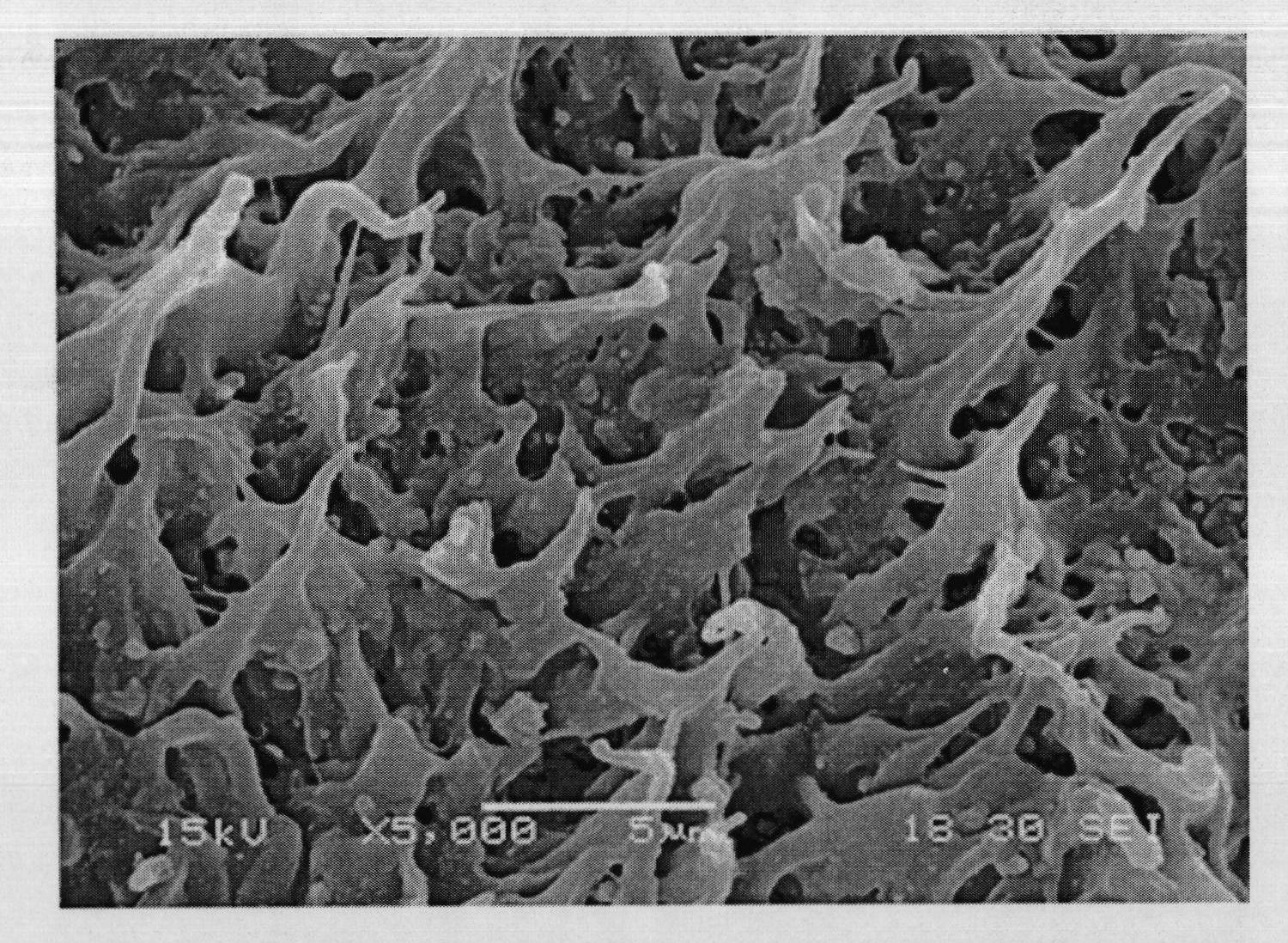

[0050] The solid weight content of P1 polyacrylate emulsion is 33.0%, the volume average particle diameter of th...

Embodiment 2

[0054] Based on the total weight of the monomer as 100 parts, add 0.5 parts of alkylphenol polyoxyethylene ether (OP-10) and 2 parts of sodium dodecylbenzenesulfonate into the reaction kettle, add 300 parts of water, mix well and then heat up To 75°C, add 15 parts of isobutyl acrylate, after pre-emulsification, add 0.2 parts of potassium persulfate to initiate polymerization, keep the reaction at 80°C for 20 minutes, and obtain polyacrylate soft monomer seed emulsion;

[0055] Add 10 parts of isobutyl acrylate, 45 parts of methyl methacrylate, and 30 parts of vinyl acetate dropwise at 80°C to the seed emulsion to continue the reaction, during which 0.4 parts of potassium persulfate are added, react for 0.5 hours, and the monomers are added dropwise After completion, add 0.2 parts of potassium persulfate, keep warm for 1 hour, then cool and discharge to obtain polyacrylate elastomer emulsion P2.

[0056] The weight solid content of the P2 polyacrylate emulsion is 24.8%, the vol...

Embodiment 3

[0061] Based on 100 parts of the total monomer mass, add 1.5 parts of alkylphenol polyoxyethylene ether (OP-10) and 0.8 parts of sodium dodecylbenzenesulfonate into the reaction kettle, add 110 parts of water, mix well and then heat up To 80°C, add 20 parts of n-octyl methacrylate, add 0.2 parts of ammonium persulfate after pre-emulsification to initiate polymerization, keep the reaction at 95°C for 20 minutes, and obtain polyacrylate soft monomer seed emulsion;

[0062] Add 15 parts of n-octyl acrylate and 65 parts of styrene dropwise at 85°C to the seed emulsion to continue the reaction. During this period, add 0.15 parts of ammonium persulfate and react for 1 hour. Parts, heat preservation for 2.5 hours, cooling and discharging to obtain high molecular weight polyacrylate elastomer emulsion P3.

[0063] The solid content of the P3 polyacrylate emulsion is 47.0%, the volume average particle diameter of latex particles is 220nm, the Tg is 11.9°C, and the weight average molecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com