Supercritical fluid injection molding foaming polylactic acid foam material and preparation method thereof

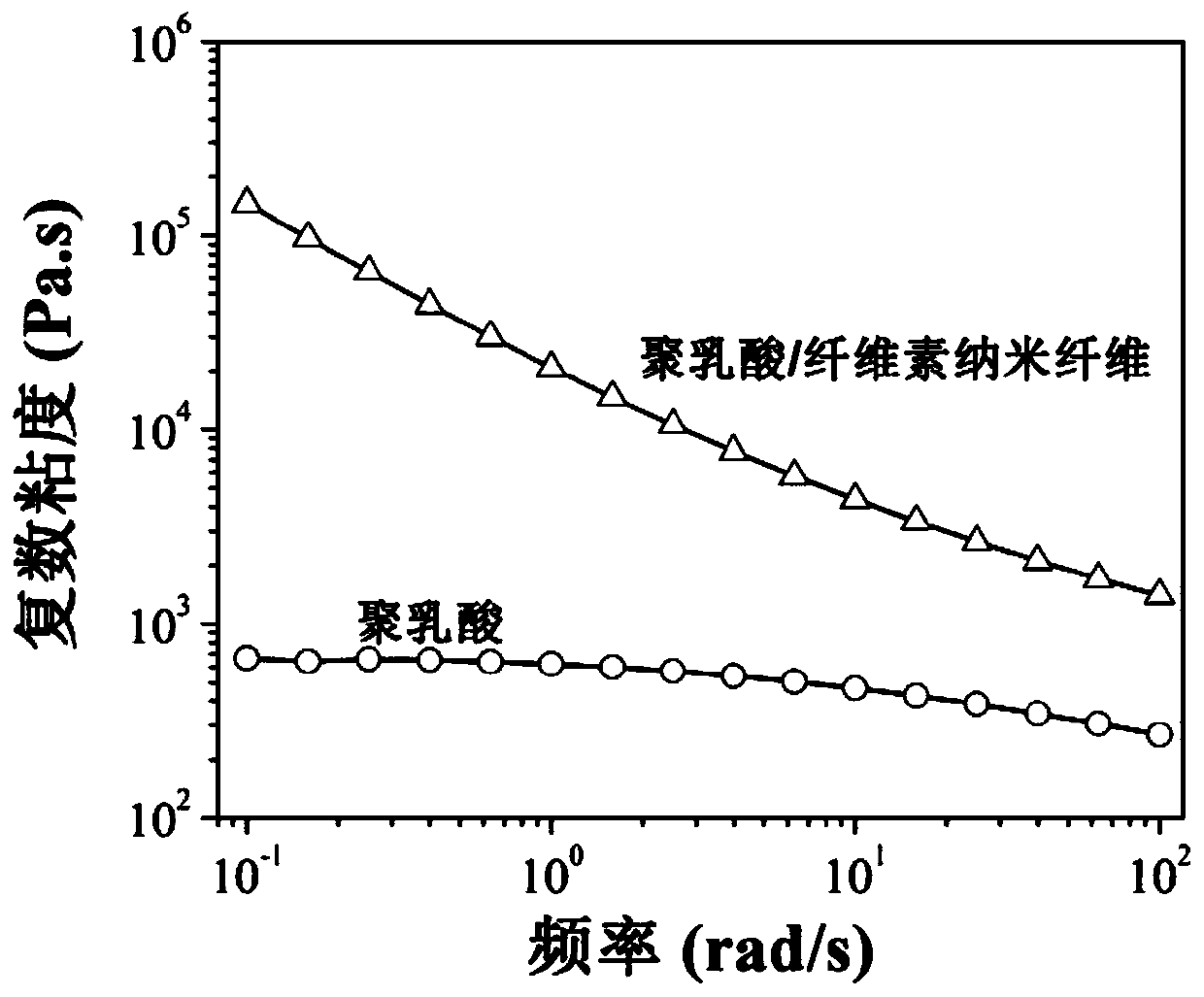

A technology of supercritical fluids and foam materials, which is applied in the post-treatment and modification of cellulose pulp, can solve the problems of affecting the biological properties of PLA materials, difficult to large-scale industrial application, and reducing the degradability of materials. Melt properties, ease of industrial production, and the effect of improving melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) The dried cellulose pulp is put into a mixed liquor whose volume ratio of toluene, acetic acid, perchloric acid and acetic anhydride is 100:80:0.2:1, wherein the mass fraction of cellulose nanofibers is 5%, at room temperature Stir at low temperature for 1 hour to obtain modified cellulose nanofiber slurry, and then wash with ethanol and deionized water in sequence to obtain an aqueous solution of surface-modified cellulose nanofibers.

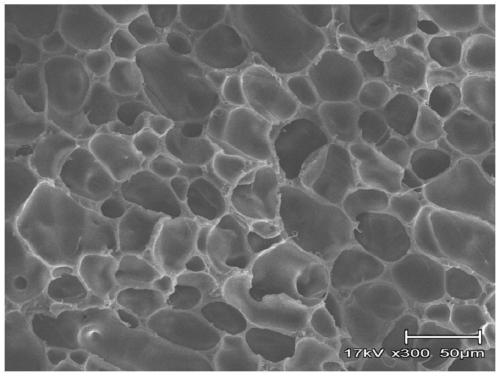

[0043] (2) PLA with a weight-average molecular weight of 400,000 is added through the main feeding port of the twin-screw extruder, and then the above-mentioned modified cellulose nanofiber aqueous solution is added by the auxiliary feeding port of the extruder, and the high-shear Shear force melt blending, while removing water vapor through the exhaust port on the extruder barrel, repeated extrusion twice, the temperature of the blending barrel for the first extrusion was 99 ° C, and the screw speed was 100 rpm; the second time Ext...

Embodiment 2

[0047] (1) Putting the dried cellulose pulp into toluene, acetic acid, perchloric acid and acetic anhydride in a volume ratio of 100:80:0.4:3, wherein the mass fraction of cellulose nanofibers is 10%, at room temperature Stir for 2 hours to obtain a modified cellulose nanofiber slurry, and then wash with ethanol and deionized water in sequence to obtain a surface-modified cellulose nanofiber aqueous solution.

[0048] (2) PLA with a weight-average molecular weight of 250,000 is added through the main feeding port of the twin-screw extruder, and then the above-mentioned modified cellulose nanofiber solution is added through the auxiliary feeding port of the extruder, and the high-shear Shear force melt blending, while removing water vapor through the exhaust port on the barrel of the extruder, repeated extrusion twice, the temperature of the blending barrel for the first extrusion was 97 ° C, and the screw speed was 130 rpm; the second time The temperature of the extrusion blen...

Embodiment 3

[0052] (1) Putting the dried cellulose pulp into toluene, acetic acid, perchloric acid and acetic anhydride in a volume ratio of 100:80:0.6:5, wherein the mass fraction of cellulose nanofibers is 20%, at room temperature Stir for 3 hours to obtain a modified cellulose nanofiber slurry, and then wash with ethanol and deionized water in sequence to obtain a surface-modified cellulose nanofiber aqueous solution.

[0053] (2) PLA with a weight-average molecular weight of 150,000 is added through the main feeding port of the twin-screw extruder, and then the above-mentioned modified cellulose nanofiber solution is added through the auxiliary feeding port of the extruder, and the high-shear Shear force melt blending, while removing water vapor through the exhaust port on the extruder barrel, repeated extrusion twice, the temperature of the blending barrel for the first extrusion was 95°C, and the screw speed was 160rpm; the second time Extrusion blending cylinder temperature is 160 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com