Sol-gel method for preparing micro/nano titanium dioxide and lyophobic film thereof on metal surfaces

A technology of sol-gel method and hydrophobic film, which is applied to the device for coating liquid on the surface, special surface, coating, etc., which can solve the problems of high price, large film roughness, and accelerated dirt deposition, so as to improve corrosion resistance The performance, process and equipment are simple, and the effect of reducing cracks and other defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

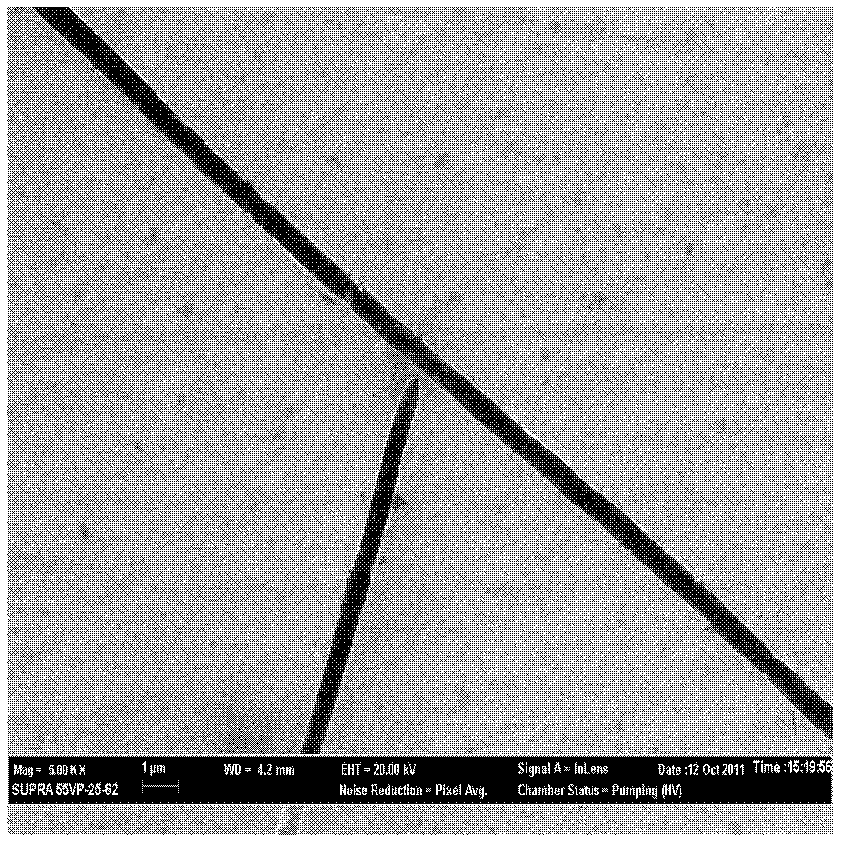

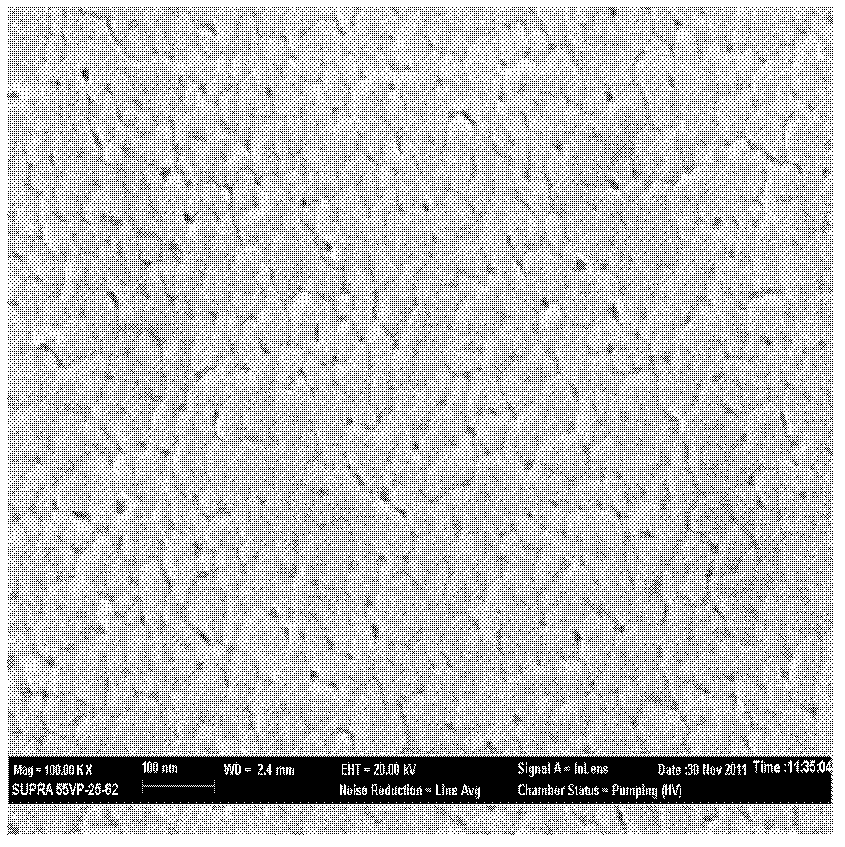

Image

Examples

Embodiment 1

[0044] (a) Base pretreatment polishing: Polish the stainless steel surface with a polishing machine equipped with a 200-mesh grinding wheel, and constantly change the grinding direction until the oxides and deep scratches on the surface are removed; use a 400-mesh grinding wheel. The polishing machine grinds the stainless steel surface, and constantly changes the grinding direction until the scratches left by the 200-mesh grinding wheel are removed; the stainless steel surface is polished with a polishing machine equipped with a 600-mesh grinding wheel, and the grinding direction is constantly changed during grinding , until the scratches left by the 400-mesh grinding wheel are removed; the commercially available green polishing soap is coated on the wool felt of the polishing machine, and the polished stainless steel substrate is polished until the surface is flat and bright, and the polished surface is rough Degree Ra = 0.0453 μm. Ultrasonic cleaning: Use a mixed solution co...

Embodiment 2

[0049](a) Base pretreatment polishing: Polish the stainless steel surface with a polishing machine equipped with a 200-mesh grinding wheel, and constantly change the grinding direction until the oxides and deep scratches on the surface are removed; use a 400-mesh grinding wheel. The polishing machine grinds the stainless steel surface, and constantly changes the grinding direction until the scratches left by the 200-mesh grinding wheel are removed; the stainless steel surface is polished with a polishing machine equipped with a 600-mesh grinding wheel, and the grinding direction is constantly changed during grinding , until the scratches left by the 400-mesh grinding wheel are removed; the commercially available green polishing soap is coated on the wool felt of the polishing machine, and the polished stainless steel substrate is polished until the surface is flat and bright, and the polished surface is rough Degree Ra = 0.0425 μm. Ultrasonic cleaning: Use a mixed solution con...

Embodiment 3

[0054] (a) Base pretreatment polishing: Polish the stainless steel surface with a polishing machine equipped with a 200-mesh grinding wheel, and constantly change the grinding direction until the oxides and deep scratches on the surface are removed; use a 400-mesh grinding wheel. The polishing machine grinds the stainless steel surface, and constantly changes the grinding direction until the scratches left by the 200-mesh grinding wheel are removed; the stainless steel surface is polished with a polishing machine equipped with a 600-mesh grinding wheel, and the grinding direction is constantly changed during grinding , until the scratches left by the 400-mesh grinding wheel are removed; the commercially available green polishing soap is coated on the wool felt of the polishing machine, and the polished stainless steel substrate is polished until the surface is flat and bright, and the polished surface is rough Degree Ra = 0.0406 μm. Ultrasonic cleaning: Use a mixed solution co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com