Coating liquid for preventing defects on paint surface after paint spraying

A coating liquid and paint surface technology, which is applied in the field of paint spraying, can solve the problems of the discount of the service life of the paint surface, the chromatic aberration of the paint surface, and the impact on the appearance, and achieve the effects of improving quality, wide application prospects, and high curing temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

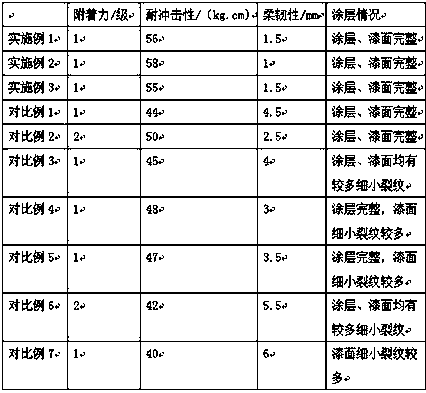

Examples

Embodiment 1

[0022] A coating solution for preventing defects on the paint surface after paint spraying, the preparation method is as follows:

[0023] 1) Add graphene oxide into deionized water, oscillate and disperse under 200W ultrasonic wave for 25 minutes to prepare graphene oxide dispersion liquid, then add sodium borohydride and sodium bisulfite, continue ultrasonic dispersion for 15 minutes, and then put it in a constant temperature water bath Heating to 90°C, constant temperature reaction for 6h, then washing with deionized water until neutral, and freeze-drying at -55°C for 48h to prepare graphene airgel;

[0024] 2) Add the graphene airgel into the tetrahydrofuran solution, pass through nitrogen to remove the air in the reaction system, then add triethylamine, stir at a speed of 100r / min for 30min, then move to an ice-water bath, slowly add the A mixed solution composed of 2-bromoisobutyryl bromide and tetrahydrofuran, the mixed solution is added within 2 hours, and then reacted...

Embodiment 2

[0034] A coating solution for preventing defects on the paint surface after paint spraying, the preparation method is as follows:

[0035] 1) Add graphene oxide to deionized water, oscillate and disperse under 250W ultrasonic wave for 20 minutes to prepare graphene oxide dispersion liquid, then add sodium borohydride and sodium bisulfite, continue ultrasonic dispersion for 13 minutes, and then put it in a constant temperature water bath Heating to 100°C, constant temperature reaction for 5h, then washing with deionized water until neutral, and freeze-drying at -60°C for 40h to prepare graphene airgel;

[0036] 2) Add the graphene airgel into the tetrahydrofuran solution, pass nitrogen to remove the air in the reaction system, then add triethylamine, stir at a speed of 130r / min for 25min, then move to an ice-water bath, slowly add the A mixed solution composed of 2-bromoisobutyryl bromide and tetrahydrofuran, the mixed solution was added within 2.5 hours, and then reacted at ro...

Embodiment 3

[0046] A coating solution for preventing defects on the paint surface after paint spraying, the preparation method is as follows:

[0047] 1) Add graphene oxide into deionized water, oscillate and disperse under 300W ultrasonic waves for 15 minutes to obtain a graphene oxide dispersion, then add sodium borohydride and sodium bisulfite, continue ultrasonic dispersion for 10 minutes, and then put it in a constant temperature water bath Heating to 110°C, constant temperature reaction for 6h, then washing with deionized water until neutral, and freeze-drying at -70°C for 36h to prepare graphene airgel;

[0048] 2) Add the graphene airgel into the tetrahydrofuran solution, pass through nitrogen to remove the air in the reaction system, then add triethylamine, stir at a speed of 150r / min for 20min, then move to an ice-water bath, slowly add the A mixed solution composed of 2-bromoisobutyryl bromide and tetrahydrofuran, the mixed solution is added within 3 hours, and then reacted at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com