Laser cutting method

A technology of laser cutting and cutting trajectory, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of high laser energy density, affecting the quality and concentration of display panel products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Wherein, the accompanying drawings are only used for exemplary illustration, and represent only schematic diagrams, and should not be understood as limitations on this patent.

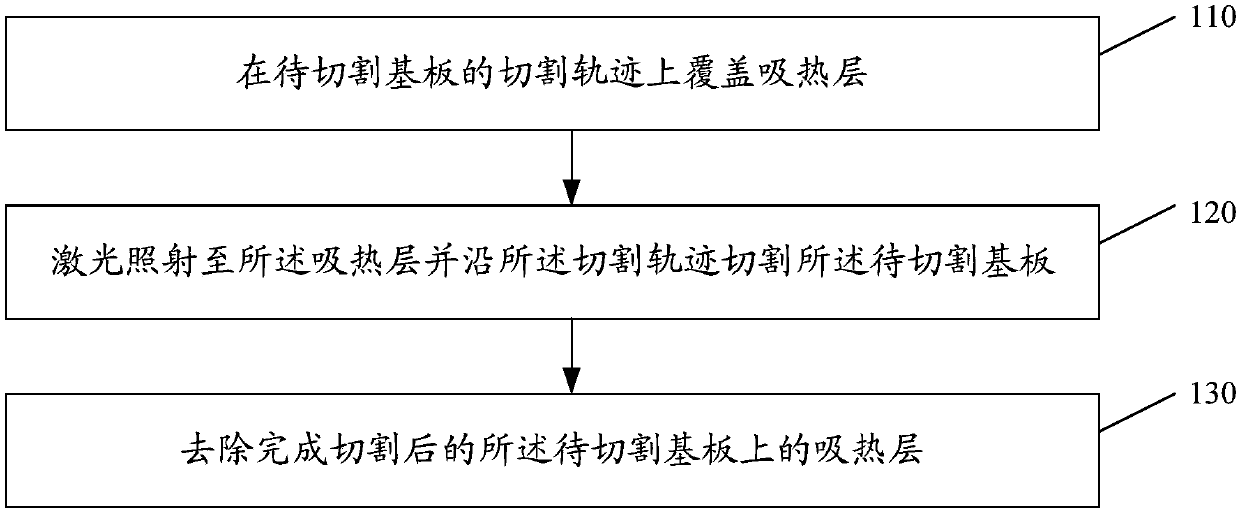

[0023] please participate figure 1 , the present invention provides a kind of laser cutting method, described laser cutting method comprises steps:

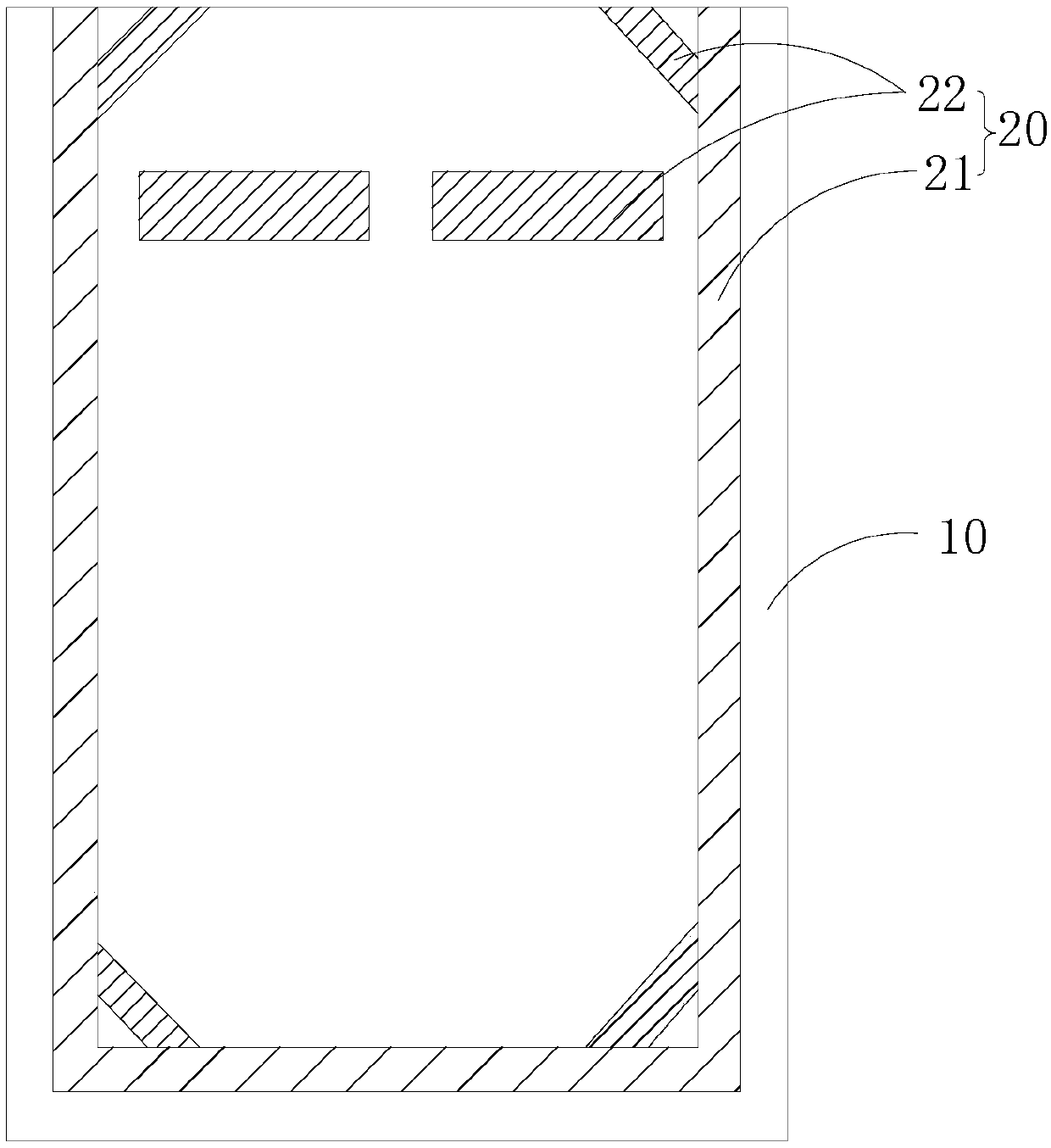

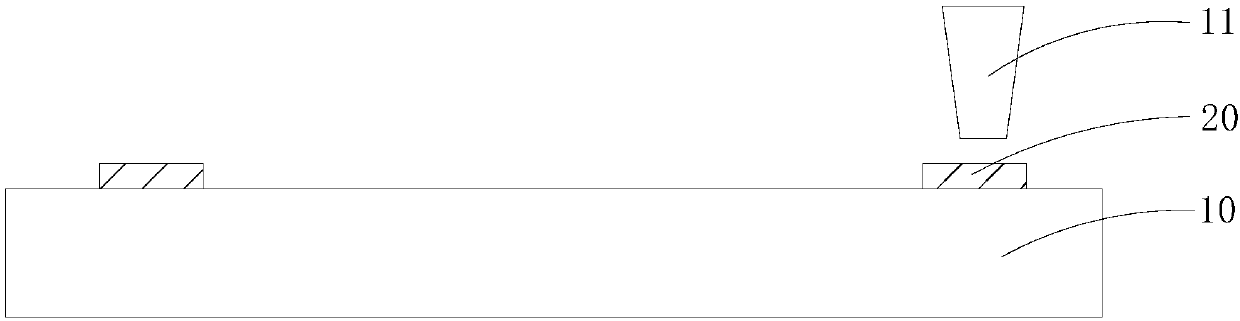

[0024] Step 110, please also refer to figure 2 and image 3 , covering the heat absorbing layer 20 on the cutting track of the substrate 10 to be cut.

[0025] In the present invention, the substrate 10 to be cut is cut by means of laser cutting. The cutting includes cutting the substrate 10 to be cut to obtain a substrate of a suitable size, and also includes chamfering and perforating the substrate 10 to be cut to obtain a substrate with a better app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com