Method for preparing 24CrNiMo bainite alloy steel by using selective laser melting technology

A laser selective melting and alloy steel technology, applied in the field of materials, can solve the problems of complex phase and phase transformation, complex heat treatment process, high manufacturing cost, and achieve excellent mechanical properties, good strength-toughness matching relationship, and excellent strength-toughness matching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

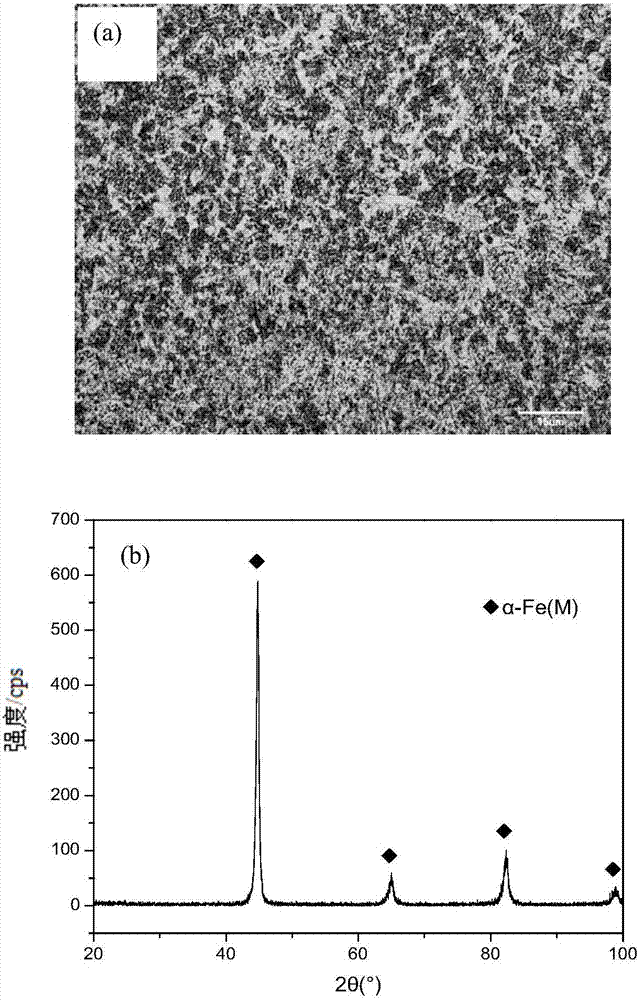

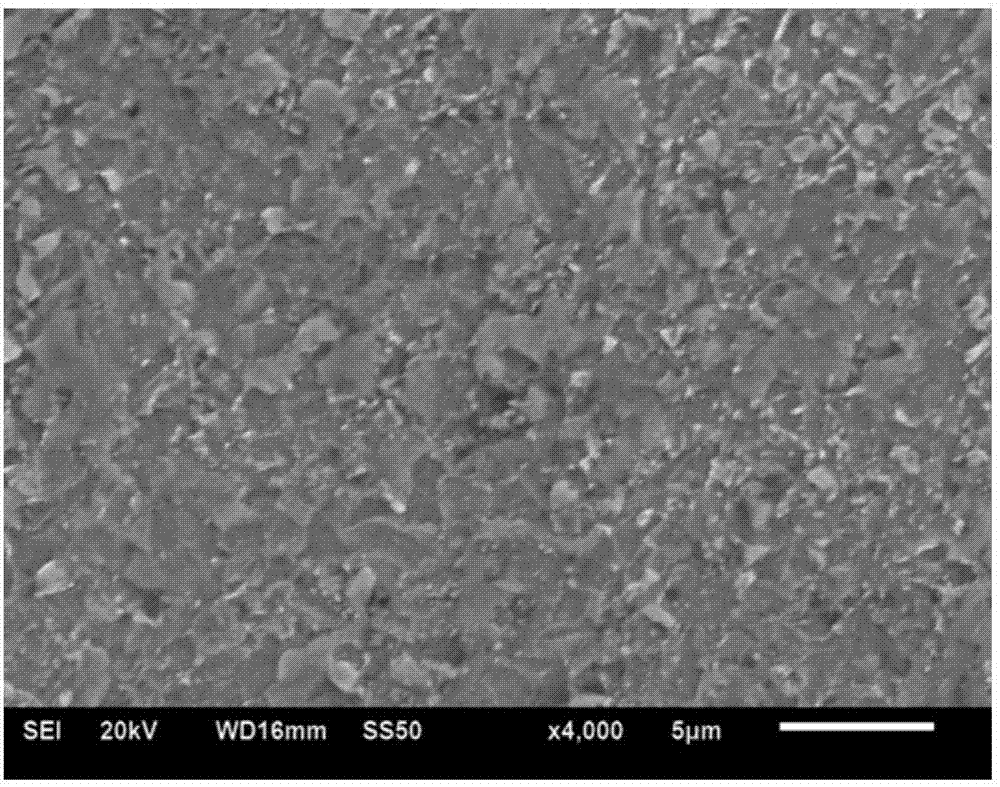

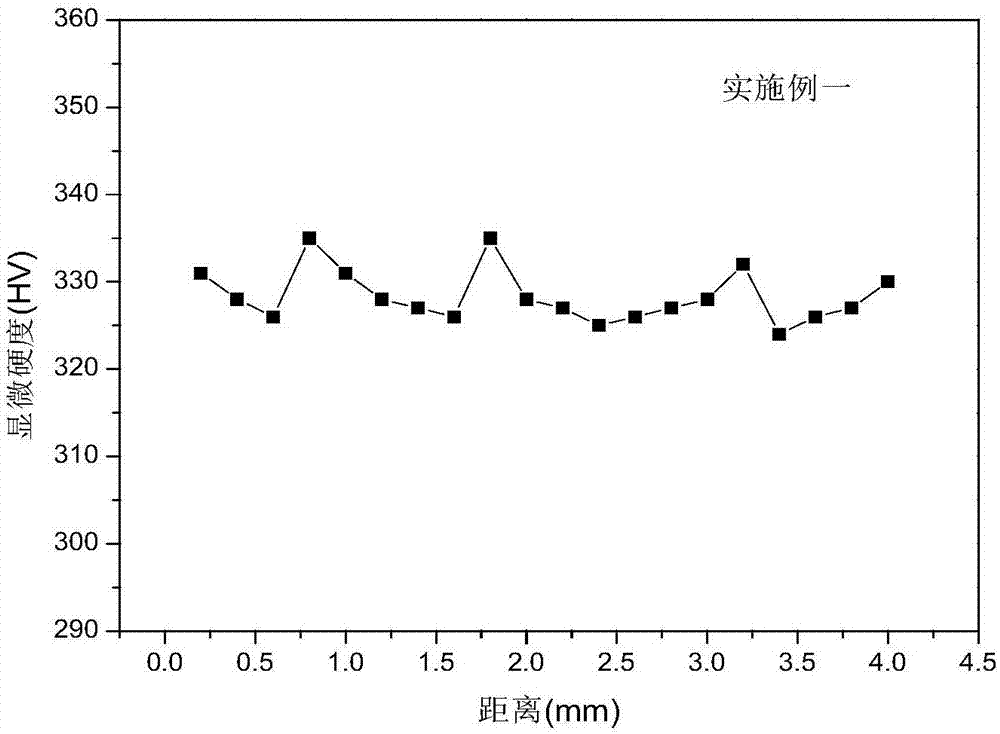

Embodiment 1

[0052] The 24CrNiMo bainite alloy steel high-speed iron brake disc is prepared by laser selective melting technology. The laser selective melting equipment used in it includes semiconductor lasers, computer systems for forming control, powder spreading device forming cylinders and atmosphere protection devices. The details are as follows Steps to implement:

[0053] Step 1: Raw material powder preparation:

[0054] (1) 24CrNiMo alloy steel powder material, the powder contains the following elements in mass percent (Wt%) content: C: 0.27%, Cr: 0.97%, Ni: 0.98%, Mo: 0.50, Mn: 0.91%, Si: 0.52 %, O: 0.02%, the balance is Fe; the sum of the mass percentages of the above elements is 100%;

[0055] (2) Sieve the above-mentioned alloy steel powder, and the particle size distribution range is preferably 15-53 μm; before use, heat it at 80° C. for 5 hours in a vacuum drying oven, and perform drying treatment;

[0056] Step 2: Formulation of scanning path and laser process parameters ...

Embodiment 2

[0079] Utilize laser selective melting technique to prepare 24CrNiMo bainite alloy steel metal sample, preparation method is the same as embodiment 1, wherein difference is to change the powder pretreatment drying temperature and time in (2) of step 1, step 2 (1) The layer thickness of the three-dimensional model in layered discrete processing, the laser selective melting process parameters in (2), the thickness of the 24CrNiMo powder layer in step 3 (2) and the volume energy density in step 3 (3), specifically:

[0080] Drying temperature and time of powder pretreatment: before use, heat it in a vacuum drying oven at 100°C for 8 hours for drying treatment;

[0081] Layer thickness during layered discrete processing of the 3D model: construct a 3D model of the part to be formed, and use the programming software that comes with the laser to perform layered discrete processing of the 3D data of the part to be formed. The thickness of each layer is uniform, and the thickness is se...

Embodiment 3

[0099] Utilize laser selective melting technique to prepare 24CrNiMo bainite alloy steel metal sample, preparation method is the same as embodiment 1, wherein difference is to change the powder pretreatment drying temperature and time in (2) of step 1, step 2 (1) The layer thickness of the three-dimensional model in layered discrete processing, the laser selective melting process parameters in (2), the thickness of the 24CrNiMo powder layer in step 3 (2) and the volume energy density in step 3 (3), specifically:

[0100] Drying temperature and time of powder pretreatment: before use, heat it in a vacuum drying oven at 90°C for 7 hours for drying treatment;

[0101] Layer thickness during layered discrete processing of the 3D model: construct a 3D model of the part to be formed, use the programming software that comes with the laser to perform layered discrete processing of the 3D data of the part to be formed, the thickness of each layer is uniform, and the thickness is set to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com