A kind of q550e high-strength steel hot-rolled coil and production method thereof

A Q550E, hot-rolled coil technology, applied in the field of metallurgy, to achieve the effect of simplifying the production process, eliminating residual stress, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

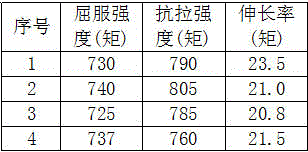

Examples

Embodiment 1

[0016] A hot-rolled coil of Q550E high-strength steel, the chemical composition of which is C: 0.07%, Si: 0.15%, Mn: 1.44%, P: 0.020%, S: 0.003%, Nb: 0.029%, V: 0.020 %, Ti: 0.089%, Als: 0.036%, and the rest are Fe and unavoidable impurities.

[0017] The production method of Q550E high-strength steel hot-rolled coils includes smelting, rolling, cooling, and crimping. The specific production process is as follows:

[0018] 1) The molten steel is smelted according to the set composition of the above mass percentage, and the molten steel is subjected to a continuous casting process to obtain a slab. In the continuous casting process, the casting speed is constant at 1.0m / min. The temperature is 80°C, and the whole protection casting is adopted; the P of the final control slab: ≤0.020%, S: ≤0.010%, T[O]≤25ppm, [N]≤50 ppm;

[0019] Blowing is strictly prohibited in the converter steelmaking process. The alloying of Nb and V elements is carried out by adding ferro-niobium and ferr...

Embodiment 2

[0024] A hot-rolled coil of Q550E high-strength steel, the chemical composition of which is C: 0.08%, Si: 0.10%, Mn: 1.50%, P: 0.015%, S: 0.004%, Nb: 0.034%, V: 0.018 %, Ti: 0.08%, Als: 0.035%, and the rest are Fe and unavoidable impurities.

[0025] The production method of Q550E high-strength steel hot-rolled coils includes smelting, rolling, cooling, and crimping. The specific production process is as follows:

[0026] 1) The molten steel is smelted according to the set composition of the above mass percentage, and the molten steel is subjected to a continuous casting process to obtain a slab. In the continuous casting process, the casting speed is constant at 1.1m / min. The temperature is 70°C, and the whole protection casting is adopted; the P of the final control slab: ≤0.020%, S: ≤0.010%, T[O]≤25ppm, [N]≤50 ppm;

[0027] Blowing is strictly prohibited in the converter steelmaking process. The alloying of Nb and V elements is carried out by adding ferro-niobium and ferro...

Embodiment 3

[0032] A hot-rolled coil of Q550E high-strength steel, the chemical composition of which is C: 0.05%, Si: 0.25%, Mn: 1.40%, P: 0.010%, S: 0.010%, Nb: 0.045%, V: 0.025 %, Ti: 0.07%, Als: 0.015%, and the rest are Fe and unavoidable impurities.

[0033] The production method of Q550E high-strength steel hot-rolled coils includes smelting, rolling, cooling, and crimping. The specific production process is as follows:

[0034]1) The molten steel is smelted according to the set composition of the above mass percentage, and the molten steel is subjected to a continuous casting process to obtain a slab. In the continuous casting process, the casting speed is constant at 1.2m / min. The temperature is 75°C, and the whole protection casting is adopted; the P of the final control slab: ≤0.020%, S: ≤0.010%, T[O]≤25ppm, [N]≤50 ppm;

[0035] Blowing is strictly prohibited in the converter steelmaking process. The alloying of Nb and V elements is carried out by adding ferro-niobium and ferro-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com