A kind of MO nanoparticle reinforced CoCRNI medium entropy alloy composite material and preparation method thereof

A nanoparticle and composite material technology, applied in the field of composite material preparation, can solve problems such as difficult to avoid oxidation or contamination of powder, and achieve good fine-grain strengthening effect, excellent mechanical properties, tensile strength and hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention provides a kind of preparation method of CoCrNi medium entropy alloy composite material reinforced by Mo nanoparticles, comprising the following steps:

[0037] (1) Weigh 1.19g of ammonium tetramolybdate powder and dissolve it in 40ml of deionized water, heat and stir at 60°C until completely dissolved to obtain ammonium tetramolybdate solution;

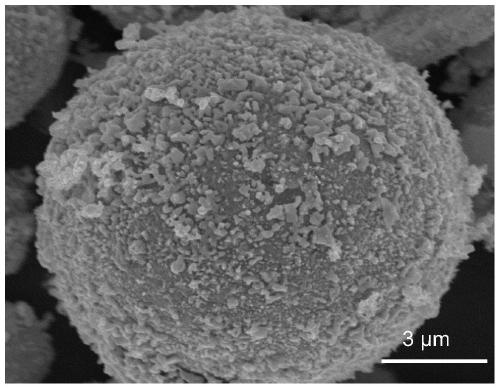

[0038] (2) Add 63.81g of gas-atomized CoCrNi medium-entropy alloy powder into the ammonium tetramolybdate solution, and evaporate the water in the beaker while stirring at an oil bath temperature of 120°C, until the powder in the beaker is completely stirred with a glass rod until it moves, and then put it into a vacuum drying oven to dry at 60°C for 24 hours to obtain a mixed powder;

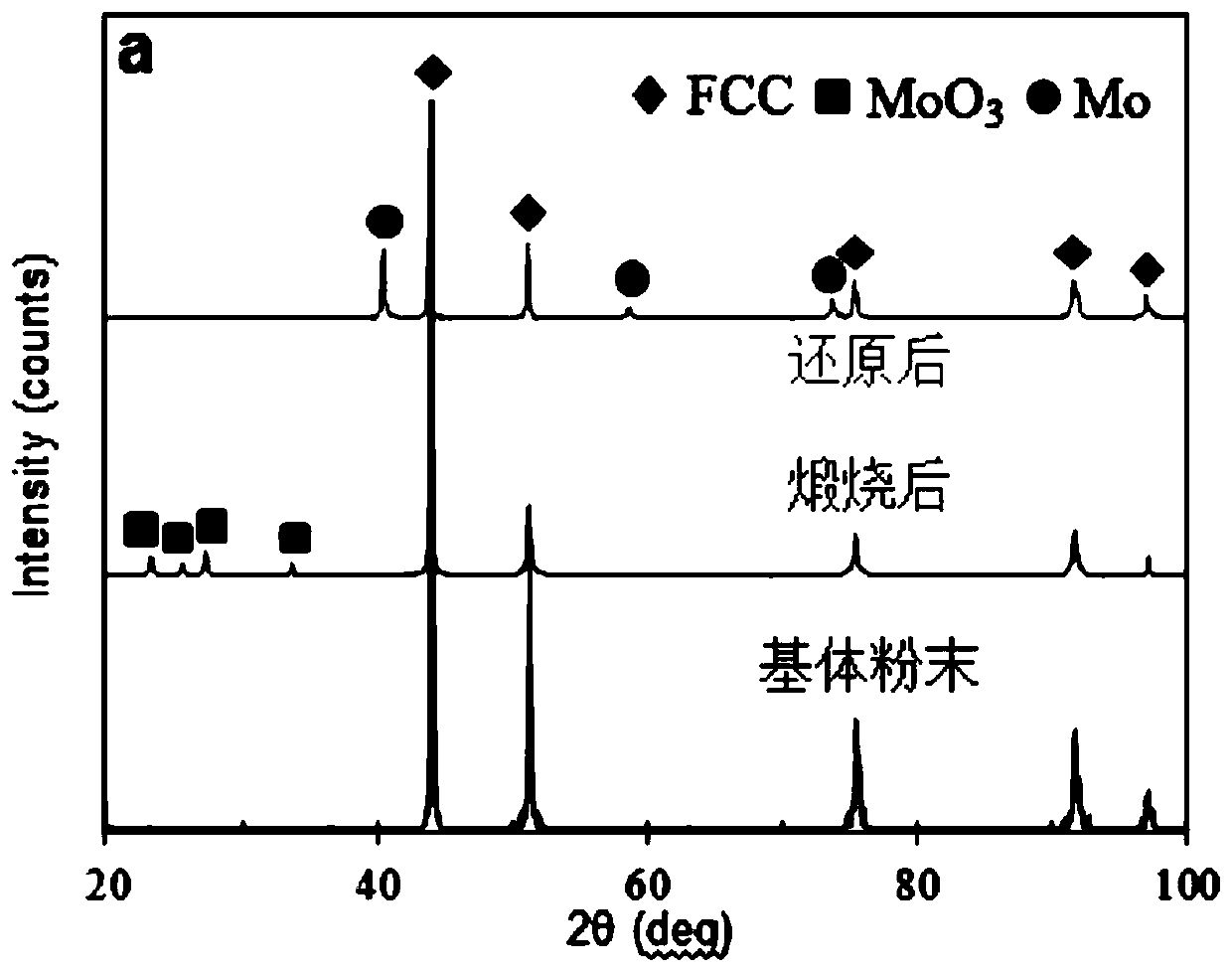

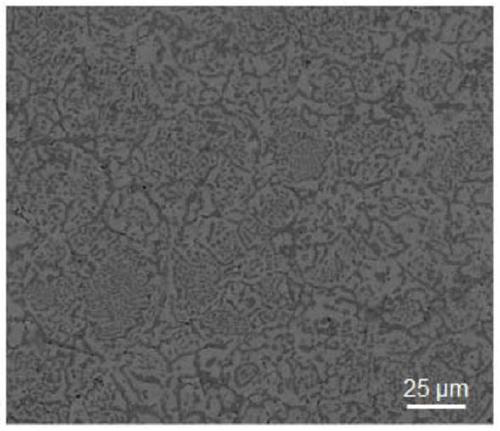

[0039] (3) Pass the mixed powder through a 80-mesh mesh sieve, and spread the sieved powder into a graphite crucible, and calcinate the powder in an argon atmosphere at a temperature of 500°C for 30 minutes to obtain a cal...

Embodiment 2

[0043] The present invention provides a kind of preparation method of CoCrNi medium entropy alloy composite material reinforced by Mo nanoparticles, comprising the following steps:

[0044] (1) Weigh 3.57g of ammonium tetramolybdate powder and dissolve it in 40ml of deionized water, heat and stir at 60°C until completely dissolved to obtain ammonium tetramolybdate solution;

[0045](2) Add 61.43g of gas-atomized CoCrNi medium-entropy alloy powder into the ammonium tetramolybdate solution, and evaporate the water in the beaker while stirring at an oil bath temperature of 120°C, until the powder in the beaker is completely stirred with a glass rod until it moves, and then put it into a vacuum drying oven to dry at 60°C for 24 hours to obtain a mixed powder;

[0046] (3) Pass the mixed powder through a 80-mesh mesh sieve, and spread the sieved powder into a graphite crucible, and calcinate the powder in an argon atmosphere at a temperature of 500°C for 30 minutes to obtain a calc...

Embodiment 3

[0050] The present invention provides a kind of preparation method of CoCrNi medium entropy alloy composite material reinforced by Mo nanoparticles, comprising the following steps:

[0051] (1) Weigh 5.97g of ammonium tetramolybdate powder and dissolve it in 40ml of deionized water, heat and stir at 60°C until completely dissolved to obtain ammonium tetramolybdate solution;

[0052] (2) Add 59.03g of gas-atomized CoCrNi medium-entropy alloy powder into the ammonium tetramolybdate solution, and evaporate the water in the beaker while stirring at an oil bath temperature of 120°C, until the powder in the beaker is completely stirred with a glass rod until it moves, and then put it into a vacuum drying oven to dry at 60°C for 24 hours to obtain a mixed powder;

[0053] (3) Pass the mixed powder through a 80-mesh mesh sieve, and spread the sieved powder into a graphite crucible, and calcinate the powder in an argon atmosphere at a temperature of 500°C for 30 minutes to obtain a cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com