A multi-grain scale core-shell structure titanium alloy bulk material and its preparation method

A core-shell structure and bulk material technology, applied in the field of powder metallurgy, can solve the problems of high raw material cost of titanium alloy spherical powder, limited strength improvement of bulk materials, and small volume fraction of fine-grained regions, etc., to achieve easy large-scale industrial production , Remarkable effect of fine-grain strengthening and high efficiency of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following describes several preferred embodiments of the present invention with reference to the accompanying drawings, so as to make the technical content clearer and easier to understand. The present invention can be embodied in many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned herein.

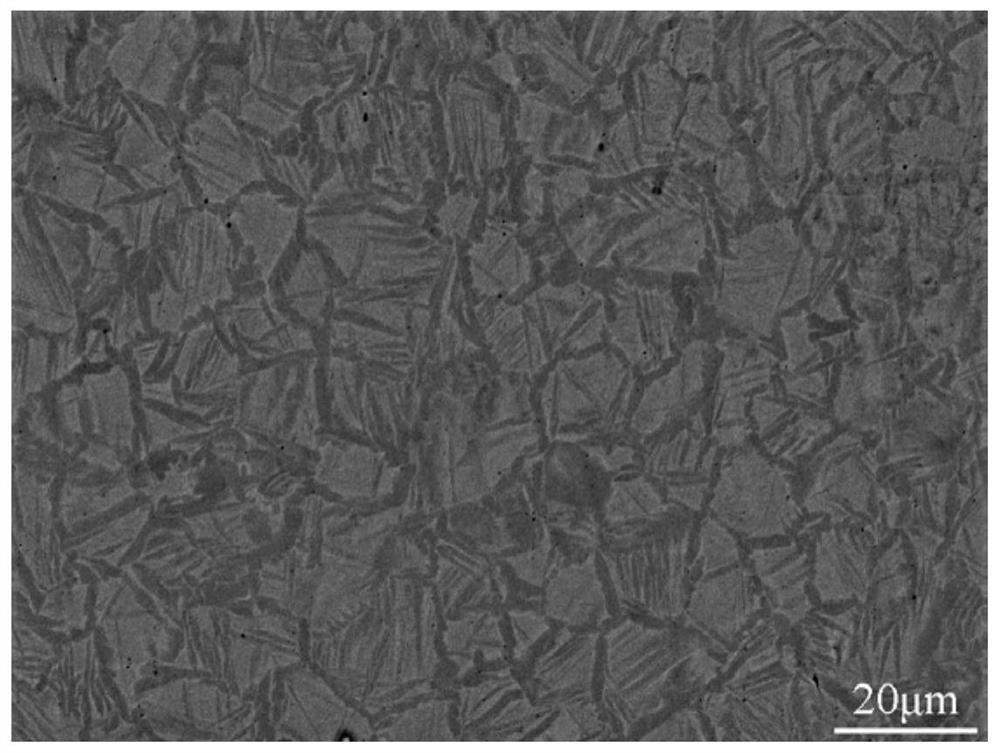

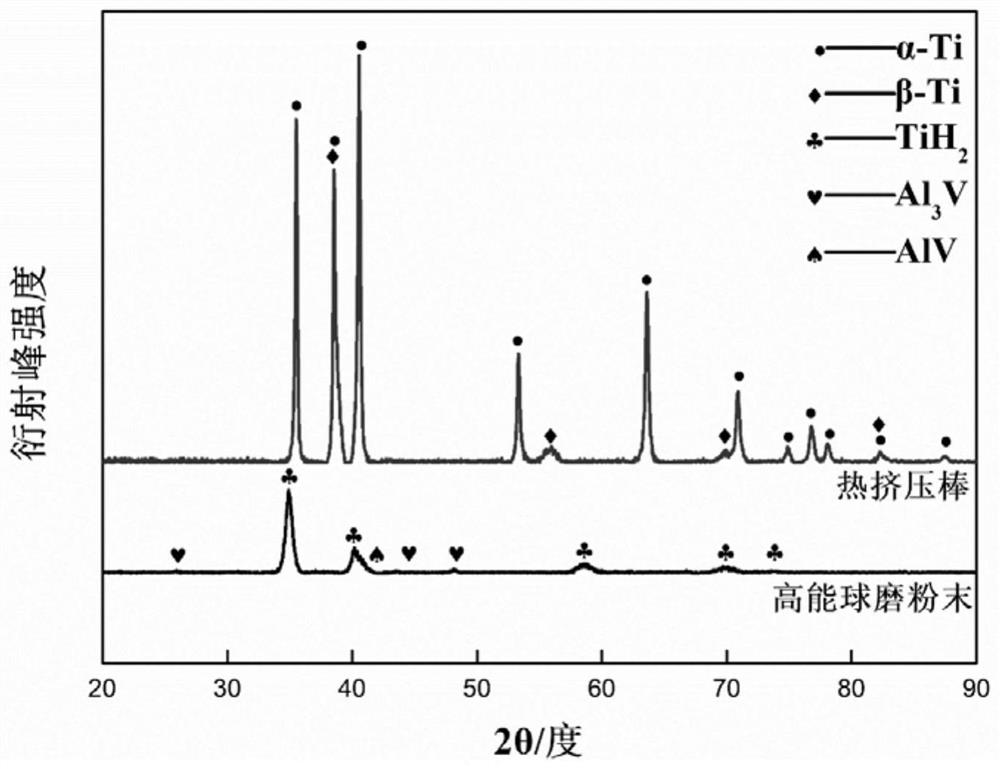

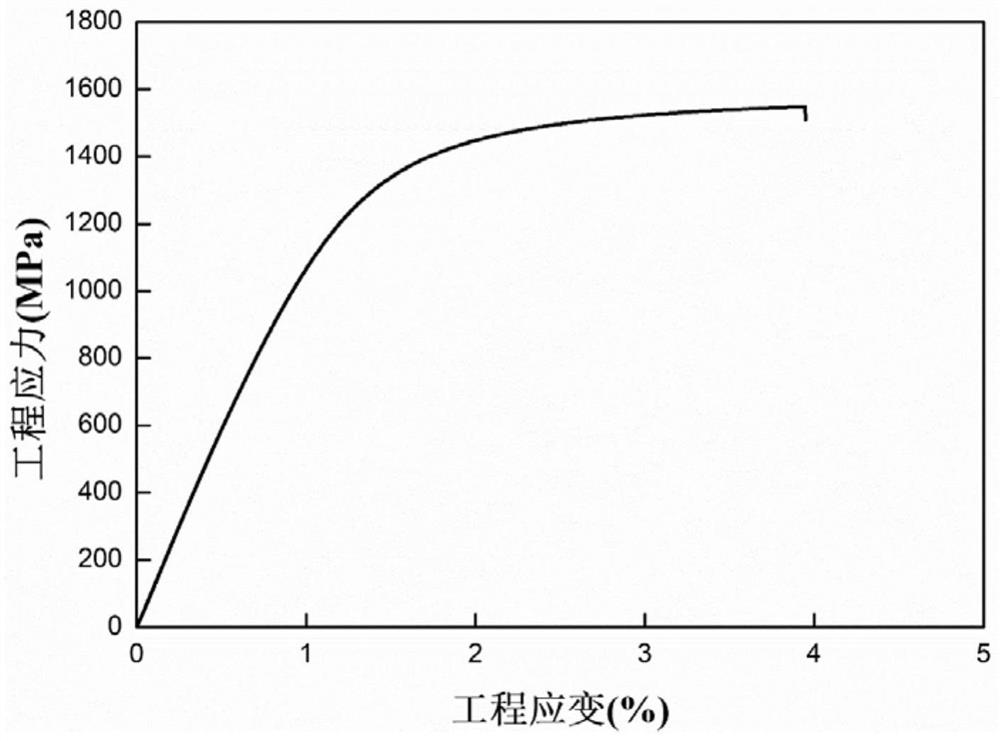

[0040] In this example, a Ti-6Al-4V alloy rod with a multi-grain scale core-shell structure was prepared through the following steps:

[0041] Step 1, weigh 45.1g of TiH respectively 2 powder and 4.9g of Al 60 V 40 Powder, the above mixed powder is put into a ball milling jar, and 15 stainless steel grinding balls with a diameter of 16mm are housed in the ball milling jar; then the ball milling jar is transferred to a glove box filled with argon, and the ball milling jar is carried out in the transition chamber of the glove box. The operation of vacuuming and argon gas is repeated three times, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com