Lithium ion battery

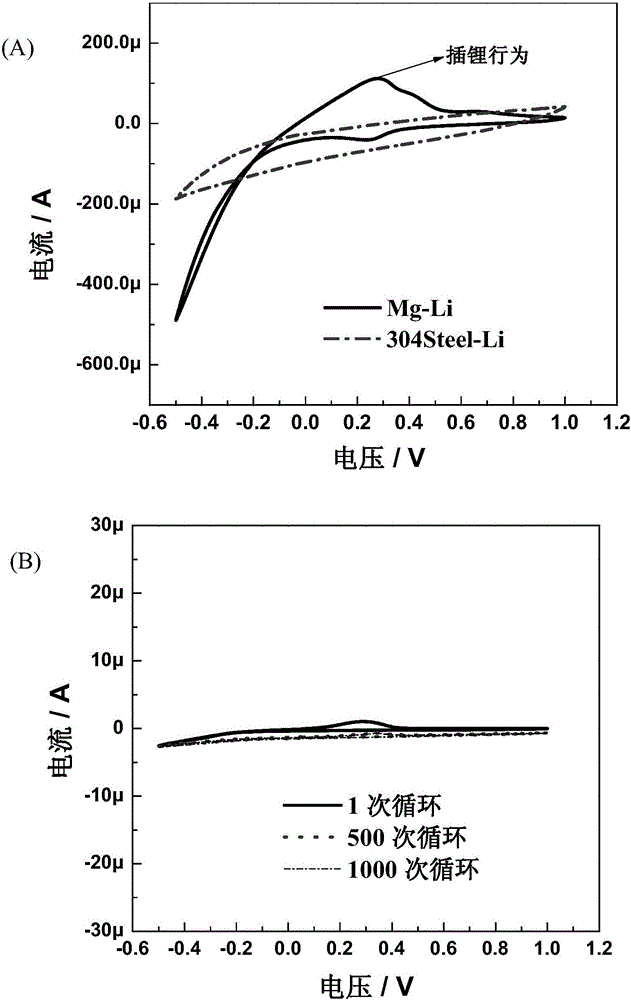

A lithium-ion battery, electrolyte technology, applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve problems such as no solution yet, and achieve inhibition of lithium insertion phenomenon, inhibition of lithium insertion behavior, holes and cracks, etc. The effect of fewer defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

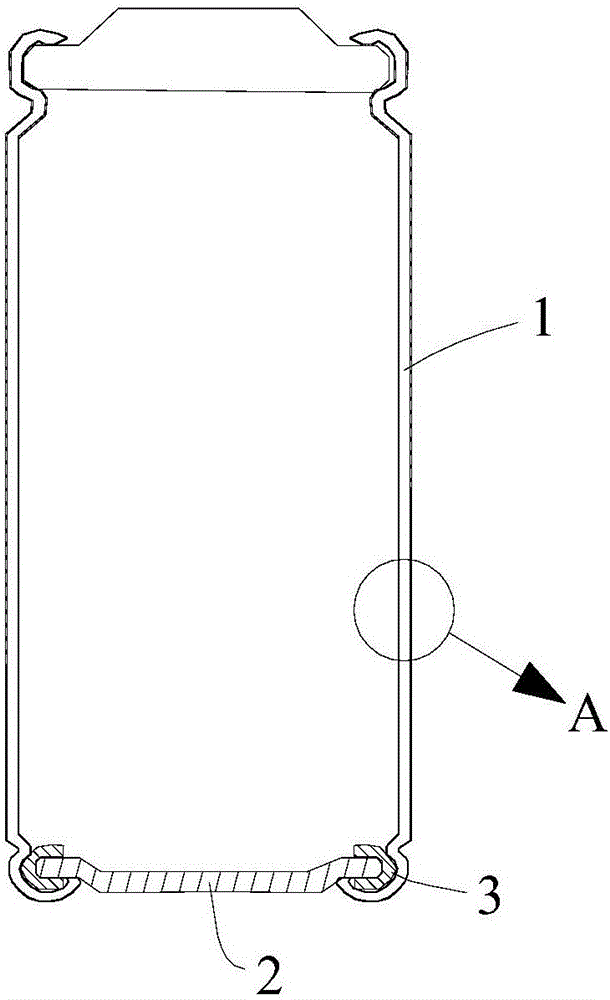

[0038] 1. Material preparation: After the AZ31B magnesium alloy is smelted, it is processed into a billet.

[0039]2. Profile processing: use a 1000-ton pipe extrusion machine to process it into a magnesium alloy pipe with a wall thickness of 0.4mm and an outer diameter of 18mm through multi-pass hot extrusion, and then process it into a magnesium alloy shell billet with a length of 70mm .

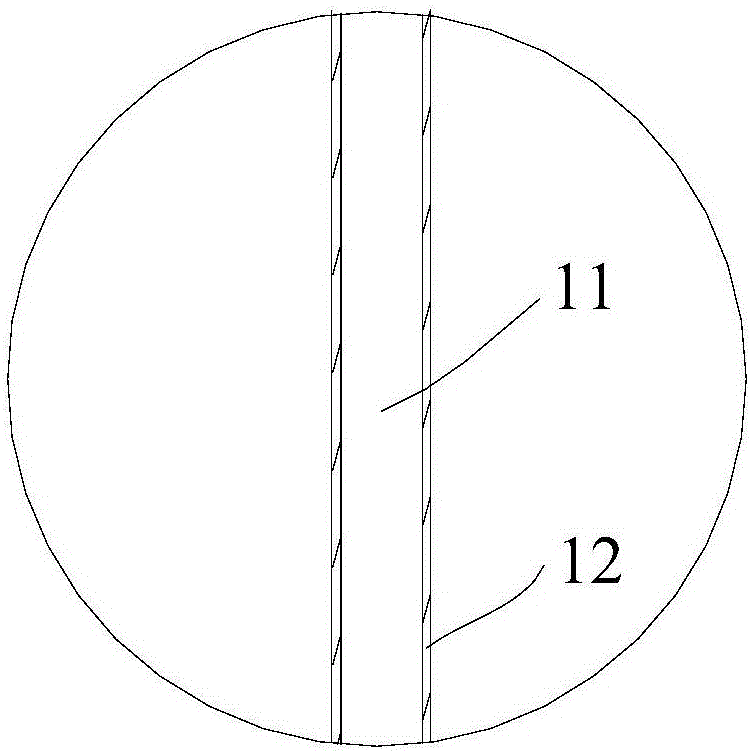

[0040] 3. Surface treatment: The magnesium alloy shell blank is pre-treated by mechanical grinding, chemical polishing, etc., and the double-pulse micro-arc oxidation technology is used to prepare ultra-micro-arc oxidation ceramic coatings. Electrolyte: potassium fluoride 15g / L, silicon Sodium phosphate 10g / L, phosphoric acid 5ml / L, potassium sodium orthophosphate 10g / L, potassium tartrate 5g / L, the rest is water, pH=3.5; temperature 25°C, micro-arc oxidation treatment 20min. Power supply mode: forward and reverse, positive final voltage is 500V, negative final voltage is 30V, current den...

Embodiment 2

[0046] 1. Material preparation: After the AZ91B magnesium alloy is smelted, it is processed into a billet.

[0047] 2. Profile processing: Using a 1000-ton pipe extruder, process it into a magnesium alloy pipe with a wall thickness of 0.4mm and an outer diameter of 26mm through multi-pass hot extrusion, and then process it into a magnesium alloy shell billet with a length of 70mm .

[0048] 3. Surface treatment: The magnesium alloy shell blank is subjected to pre-treatments such as mechanical grinding and chemical polishing, and the double-pulse micro-arc oxidation technology is used to prepare ultra-micro-arc oxidation ceramic coatings. Electrolyte: potassium fluoride 20g / L, silicon Sodium acid 15g / L, citric acid 5ml / L, sodium citrate 8g / L, sodium bicarbonate 10g / L, the rest is water, pH=9.0; temperature 25°C, micro-arc oxidation treatment 20min, power mode: forward and reverse , the positive terminal voltage is 750V, the negative terminal voltage is 40V, and the current den...

Embodiment 3

[0052] 1. Material preparation: After the WE43 magnesium alloy is smelted, it is processed into a billet.

[0053] 2. Profile processing: use a 1000-ton pipe extrusion machine to process it into a magnesium alloy pipe with a wall thickness of 0.4mm and an outer diameter of 18mm through multi-pass hot extrusion, and then process it into a magnesium alloy shell billet with a length of 70mm .

[0054] 3. Surface treatment: The magnesium alloy shell blank is pre-treated by mechanical grinding, chemical polishing, etc., and the ultra-micro-arc oxidation ceramic coating is prepared by double-pulse micro-arc oxidation technology. Electrolyte: potassium fluoride 25g / L, Sodium silicate 20g / L, hydrofluoric acid 5ml / L, sodium dihydrogen phosphate 8g / L, sodium tartrate 10g / L, the rest is water, pH=4.0; temperature 25°C, micro-arc oxidation treatment 25min, power mode: positive Reverse, positive final voltage is 500V, negative final voltage is 50V, current density 2.5A / dm 2 , frequency 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com