Automatic MIG (metal-inert gas) welding method for hard alloy and steel

A technology of hard alloys and welding methods, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve problems such as reducing the performance of hard alloys, improve bonding force, solve low productivity, and improve automation horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention are further described below with reference to the accompanying drawings and embodiments.

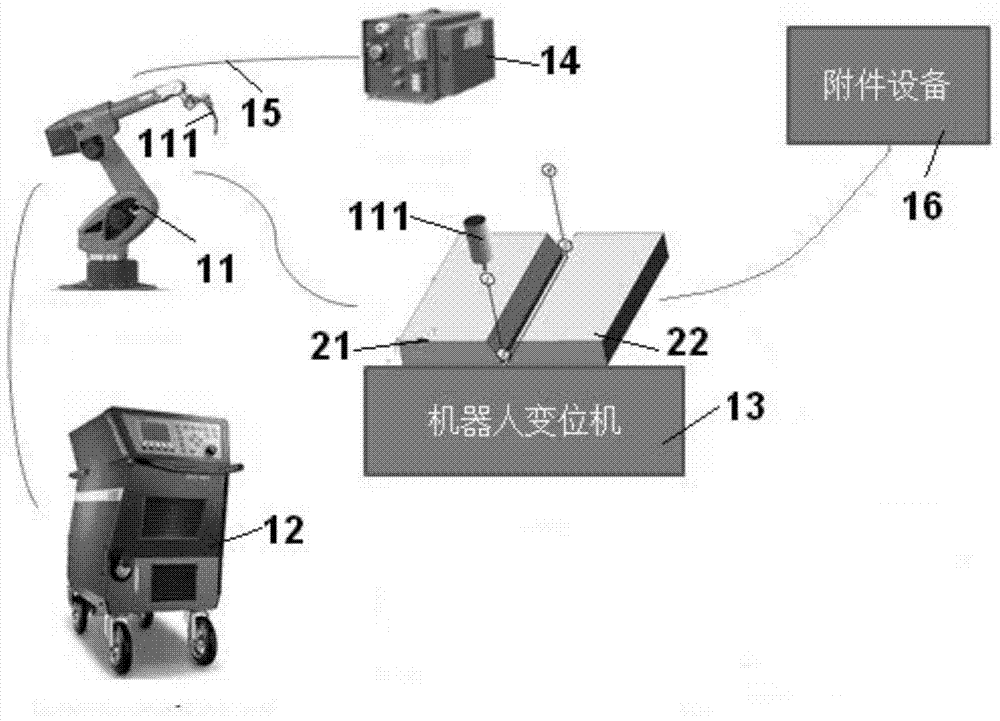

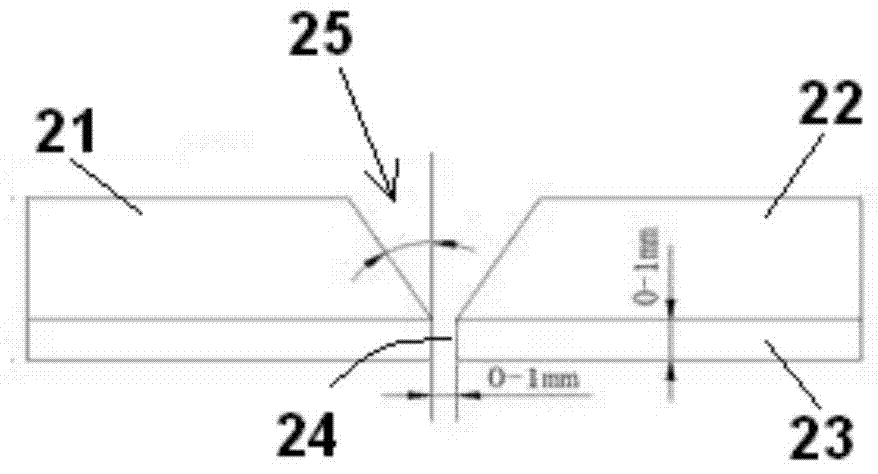

[0037] like figure 1 , figure 2 As shown in the schematic diagram of automatic welding of cemented carbide robot MIG, the welding robot 11 is connected with the welding machine 12 to realize data synchronization, and the material to be welded is cut as required and subjected to pre-welding processing according to the assembly requirements (the material to be welded can be left 0-1mm gap for easy forming) is fixed on the robot positioner 13; the wire feeding mechanism 14 attached to the welding robot 11 completes the feeding of the welding wire 15; the welding machine 12 inputs the program into the robot, inserts the process parameters, The machine controls the operation of the process parameters in real time, and the welding robot 11 performs automatic welding; other accessories such as the accessory equipment 16 refer to the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com