Permanent-magnetism wet pressure bottom-jacking type forming hydraulic press

A hydraulic press and wet pressing technology, which is applied in the field of permanent magnet wet pressing top-type hydraulic presses, can solve the problems of difficulty in accurately controlling the filling height of slurry in the cavity, large deviation in green body thickness, and poor quality of green bodies. , to achieve the effect of small deviation, guaranteed quality and good thickness consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

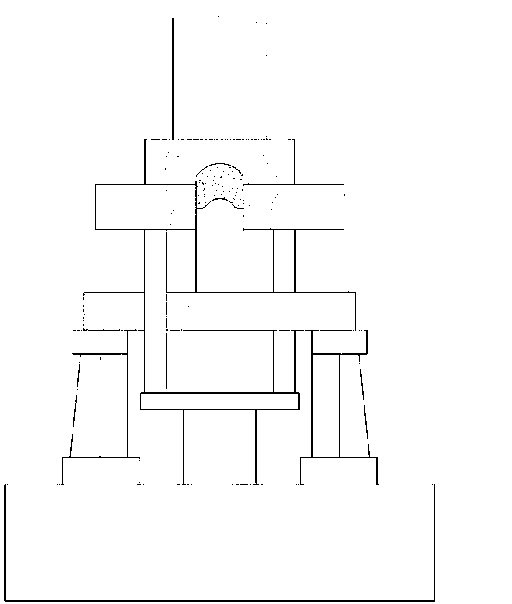

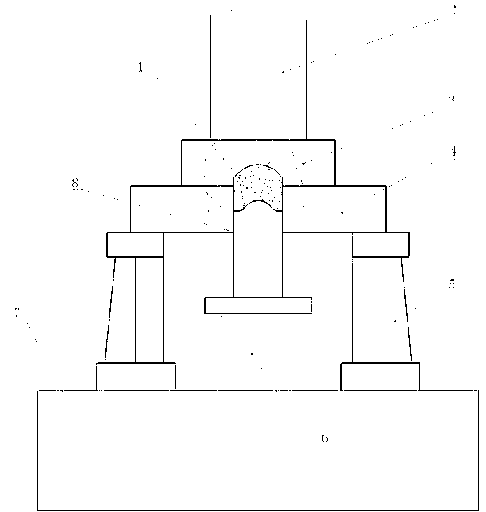

[0029] The permanent magnet wet pressure top forming hydraulic press of this embodiment includes a pressure-bearing cylinder 2, a jacking cylinder 6 and a mould. The mold is arranged between the pressure-bearing cylinder 2 and the jacking cylinder 6. Stretching oil cylinder 6 is positioned at mold below. The pressure-bearing oil cylinder 2 and the jacking oil cylinder 6 are fixed by screws and positioning devices.

[0030] The mold includes a die 3, a punch 8 and a cavity die 4. The cavity die 4 is set on the periphery of the punch 8, and cooperates with the die 3 and the punch 8 to form a cavity; the piston rod of the pressure-bearing cylinder 2 is connected to the die 3 , The piston rod of the jacking cylinder 6 is connected to the punch 8 . The working pressure of the pressurized oil cylinder 2 is greater than the working pressure of the jacking oil cylinder 6 . The cavity mold 4 is installed on the machine bed 7 through the mold base 5 .

[0031] The permanent magnet we...

Embodiment 2

[0033] The permanent magnet wet pressure top forming hydraulic press of this embodiment includes a pressure-bearing cylinder 2, a jacking cylinder 6 and a mould. The mold is arranged between the pressure-bearing cylinder 2 and the jacking cylinder 6. Stretching oil cylinder 6 is positioned at mold below. The pressure-bearing oil cylinder 2 and the jacking oil cylinder 6 are fixed by screws and positioning devices.

[0034] The mold includes a die 3, a punch 8 and a cavity die 4. The cavity die 4 is set on the periphery of the punch 8, and cooperates with the die 3 and the punch 8 to form a cavity; the piston rod of the pressure-bearing cylinder 2 is connected to the die 3 , The piston rod of the jacking cylinder 6 is connected to the punch 8 . The working pressure of the pressurized oil cylinder 2 is greater than the working pressure of the jacking oil cylinder 6 . The cavity mold 4 is installed on the machine bed 7 through the mold base 5 .

[0035] The permanent magnet we...

Embodiment 3

[0037] The permanent magnet wet pressure top forming hydraulic press of this embodiment includes a pressure-bearing cylinder 2, a jacking cylinder 6 and a mould. The mold is arranged between the pressure-bearing cylinder 2 and the jacking cylinder 6. Stretching oil cylinder 6 is positioned at mold below. The pressure-bearing oil cylinder 2 and the jacking oil cylinder 6 are fixed by screws and positioning devices.

[0038] The mold includes a die 3, a punch 8 and a cavity die 4. The cavity die 4 is set on the periphery of the punch 8, and cooperates with the die 3 and the punch 8 to form a cavity; the piston rod of the pressure-bearing cylinder 2 is connected to the die 3 , The piston rod of the jacking cylinder 6 is connected to the punch 8 . The working pressure of the pressurized oil cylinder 2 is greater than the working pressure of the jacking oil cylinder 6 . The cavity mold 4 is installed on the machine bed 7 through the mold base 5 .

[0039] The permanent magnet we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com