High-throughput preparation device and method for bulk alloy

A preparation device, high-throughput technology, applied in quenching devices, additive manufacturing, manufacturing tools, etc., can solve the problem that the structure and properties of components cannot be efficiently regulated, the influence of cooling rate on the structure and properties of components is not considered, and the unavoidable heat, etc. problems, to achieve the effect of eliminating internal stress, reducing component segregation, and slowing down cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical problems, technical solutions and beneficial effects to be solved, the present application will be described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described herein are intended to explain the present application and is not intended to limit the present application.

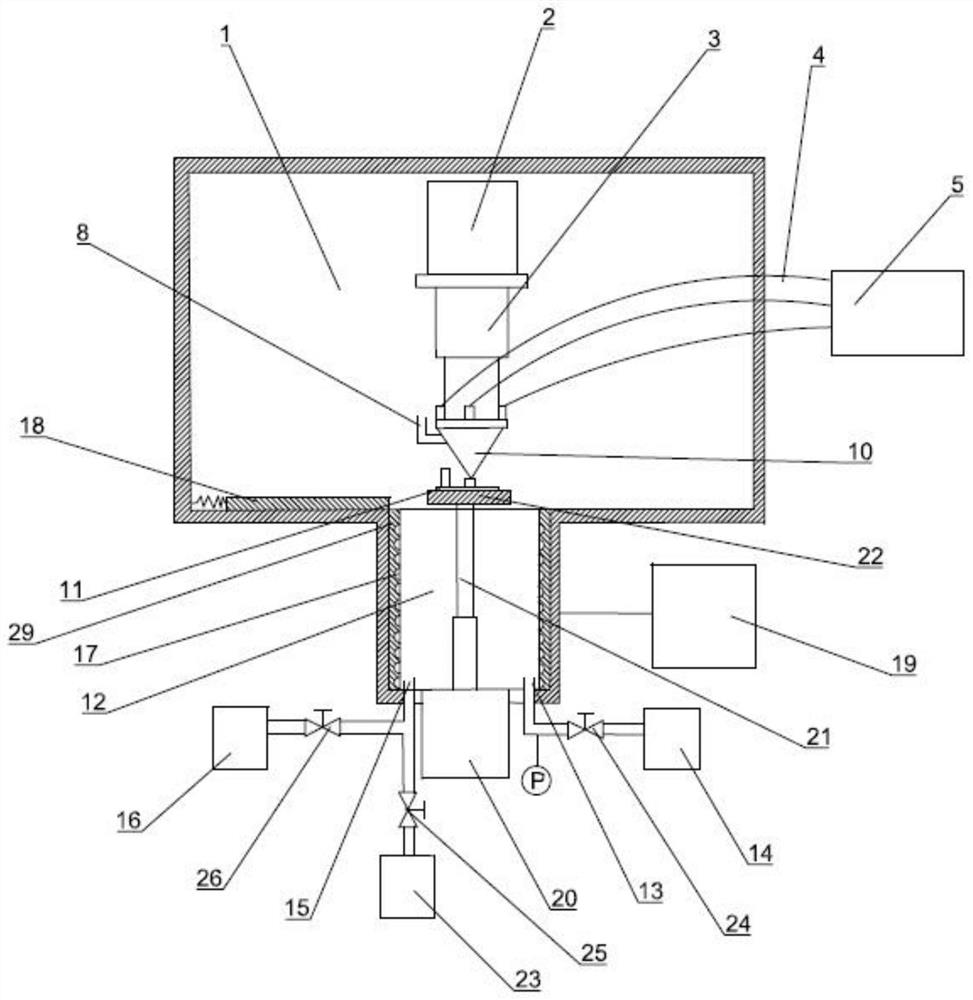

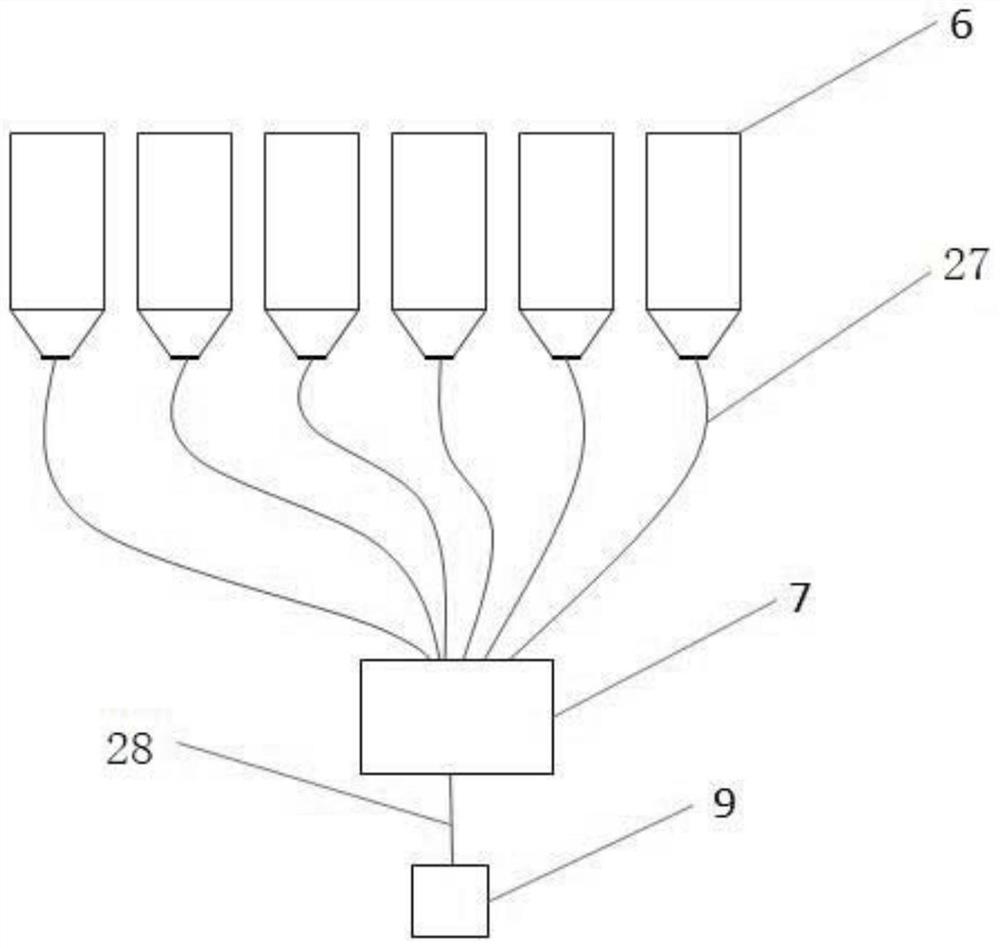

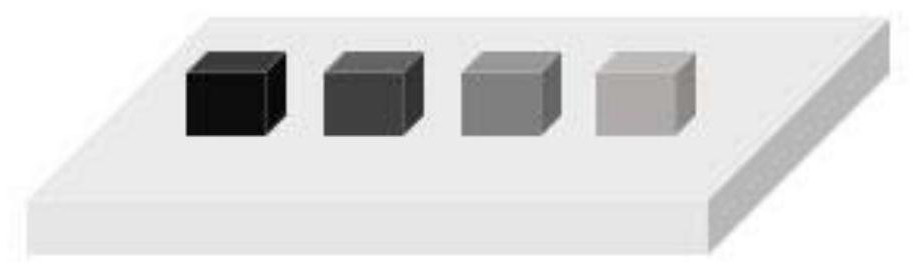

[0040] The present invention provides a block alloy high throughput preparation device, such as figure 1 As shown, it is provided with a laser molten vacuum glove box 1, a gas quencher 12, a hydraulic lifting system, a powder system 5, and a temperature control system 19. The laser molten vacuum glove box 1 is provided with a laser cladding system, a laser cladding system is connected to a powder system 5, and a plurality of metal powders are fed into a laser cladding system in a laser cladding system by powdering system 5. Treatment, the lower end of the laser molten vacuum glove box 1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com