Control method for high-mark non-oriented silicon steel cold continuous rolling edge crack

A technology of grain-oriented silicon steel and control method, applied in the direction of profile control, etc., can solve problems such as easy occurrence of edge cracks, and achieve the effect of ensuring quality, reducing edge stress of strip steel, and avoiding edge cracking problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention provide a method for controlling edge cracking of high-grade non-oriented silicon steel in continuous cold rolling, which solves the technical problem of edge cracks easily occurring in the process of high-grade non-oriented silicon steel in the prior art, and improves the quality of high-grade non-oriented silicon steel. The production capacity of continuous cold rolling of non-oriented silicon steel ensures the quality of high-grade non-oriented silicon steel.

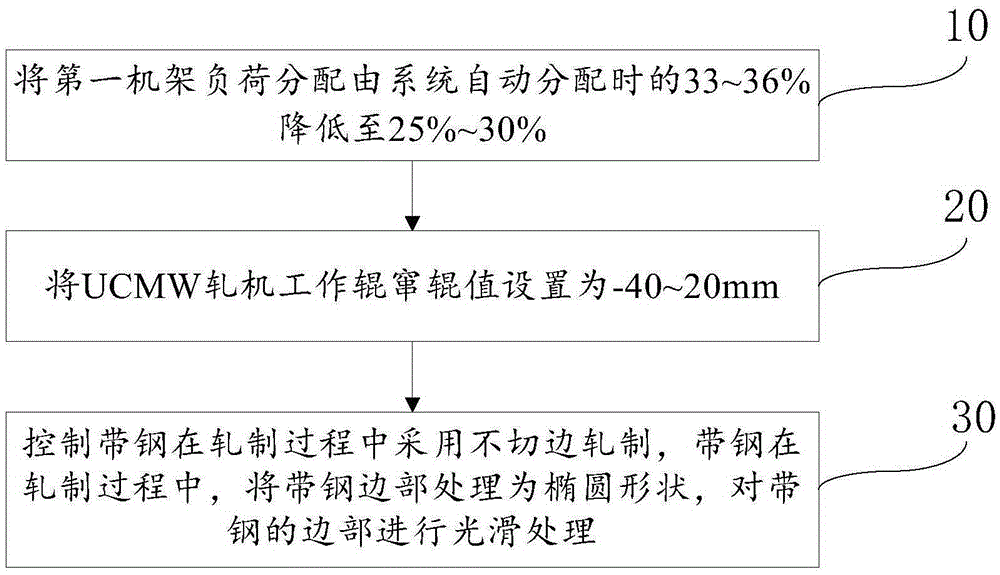

[0014] see figure 1 , the embodiment of the present invention provides a method for controlling edge cracking in continuous cold rolling of high-grade non-oriented silicon steel. The continuous cold rolling adopts UCMW five-stand continuous rolling unit, and the method includes:

[0015] Step 10, reducing the load distribution of the first rack from 33% to 36% when the system automatically distributes it to 25% to 30% (such as 25%, 27% or 30%).

[0016] Reducing the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com