Method for preparing hot rolling strip steel capable of preventing edge crack of extremely thin rolled strip steel

A hot-rolled steel strip and ultra-thin strip technology, applied in metal rolling, temperature control, etc., can solve the problems of increased equipment maintenance costs, pollution of the production site environment, and increased production costs, so as to reduce the accident rate and reduce the production cost. Consumption of auxiliary steel materials and the effect of reducing alloy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

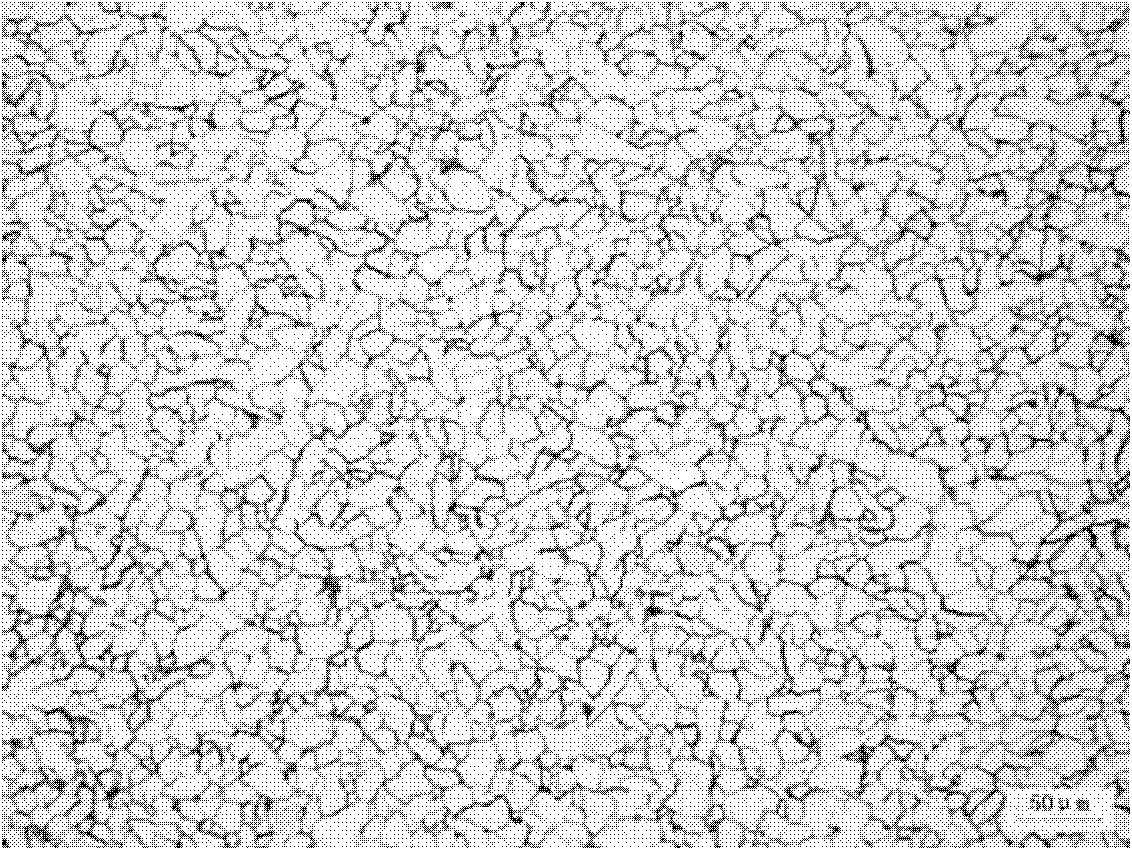

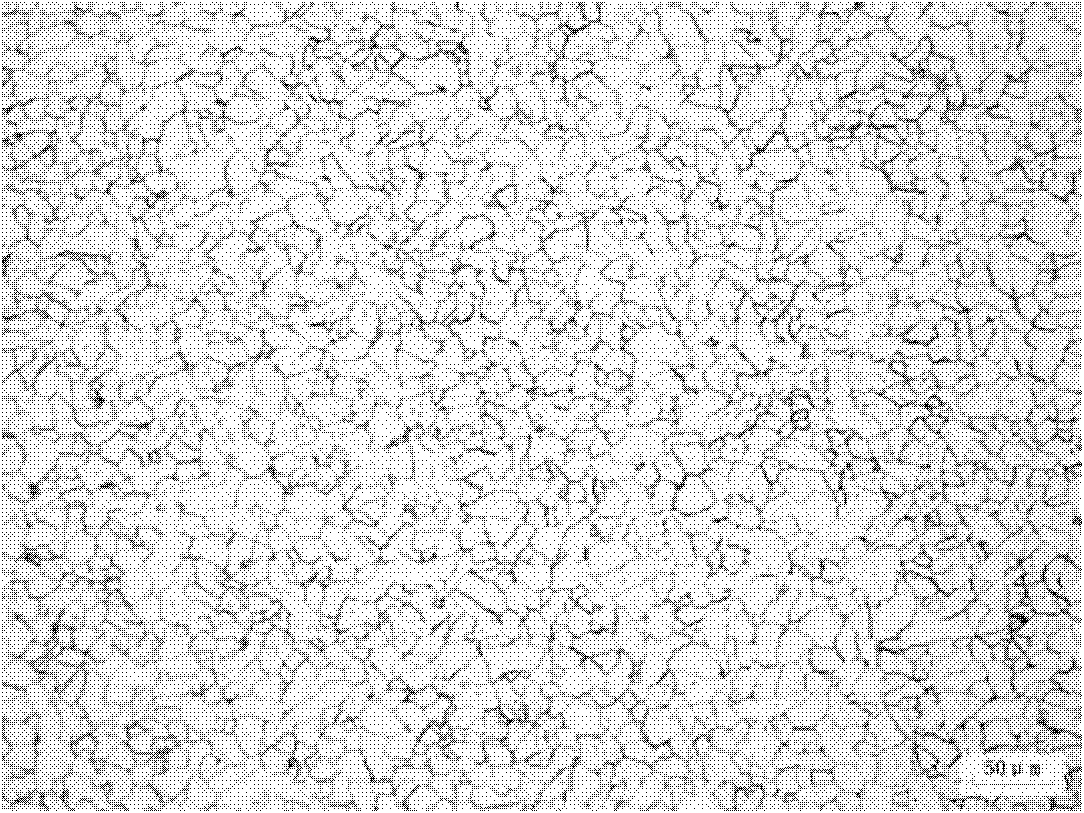

Image

Examples

Embodiment 1

[0056] The percentage by weight of the chemical composition of the slab is:

[0057] C: 0.06%, Si: 0.015%, Mn: 0.095%, P: 0.019%, S: 0.018%, Als: 0.039%, N: 0.0027%, and the rest is Fe and unavoidable impurities.

[0058] Steelmaking adopts molten iron desulfurization, converter smelting, argon blowing treatment in argon station, and continuous casting into slabs. When the molten steel is poured, the superheating degree of the molten steel is controlled at +19°C, the casting speed is controlled at 1.40m / min to 1.45m / min, the casting blank width is 1050mm, and the rolled product plate width is 1015mm.

[0059] Hot rolling: heat the cold-loaded slab to 1230°C, the temperature difference between the same slabs is ≤30°C, and the furnace time is 170min; carry out rough rolling, the exit temperature of rough rolling is 1080°C, and the vertical roll before R2 of the rough rolling mill adopts automatic hydraulic control technology for width and short stroke control. The slab width B...

Embodiment 2

[0069] The percentage by weight of the chemical composition of the slab is:

[0070] C: 0.032%, Si: 0.012%, Mn: 0.19%, P: 0.018%, S: 0.0158%, Als: 0.022%, N: 0.0033%, and the rest is Fe and unavoidable impurities.

[0071] Steelmaking adopts molten iron desulfurization, converter smelting, argon blowing treatment in argon station, and continuous casting into slabs. When the molten steel is poured, the superheating degree of the molten steel is controlled at +25°C, the casting speed of the slab is controlled at 1.30m / min to 1.40m / min, the width of the slab is 1250mm, and the width of the rolled product is 1215mm.

[0072] Hot rolling: heat the cold-loaded slab to 1240°C, the temperature difference between the same slabs is ≤30°C, and the furnace time is 155 minutes; carry out rough rolling, the exit temperature of the rough rolling is 1085°C, and the vertical rolls in front of the rough rolling mill adopt the width automatic hydraulic control technology and Short stroke contro...

Embodiment 3

[0082] The percentage by weight of the chemical composition of the slab is:

[0083] C: 0.07%, Si: 0.030%, Mn: 0.29%, P: 0.025%, S: 0.008%, Als: 0.049%, N: 0.006%, and the rest is Fe and unavoidable impurities.

[0084] Steelmaking adopts molten iron desulfurization, converter smelting, argon blowing treatment in argon station, and continuous casting into slabs. When the molten steel is poured, the superheating degree of the molten steel is controlled at +15°C, the casting speed is controlled at 1.40m / min to 1.45m / min, the casting blank width is 1300mm, and the rolled product plate width is 1260mm.

[0085] Hot rolling: heat the cold-loaded slab to 1255°C, the temperature difference between the same slabs is ≤20°C, and the furnace time is 180min; carry out rough rolling, the exit temperature of rough rolling is 1090°C, and the vertical roll before rough rolling mill R2 adopts automatic hydraulic control technology for width and short stroke control. The slab width B is 1300m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com