Plastic pipe fitting burr cutting and polishing device with cooperation of opposite cutter shearing and polishing

A technology of plastic pipe fittings and polishing devices, which is applied to grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., which can solve the problems of wasting manpower, low work efficiency, and easy to injure operators, and improve work efficiency. Efficiency, standardized operation process, and the effect of avoiding corner cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

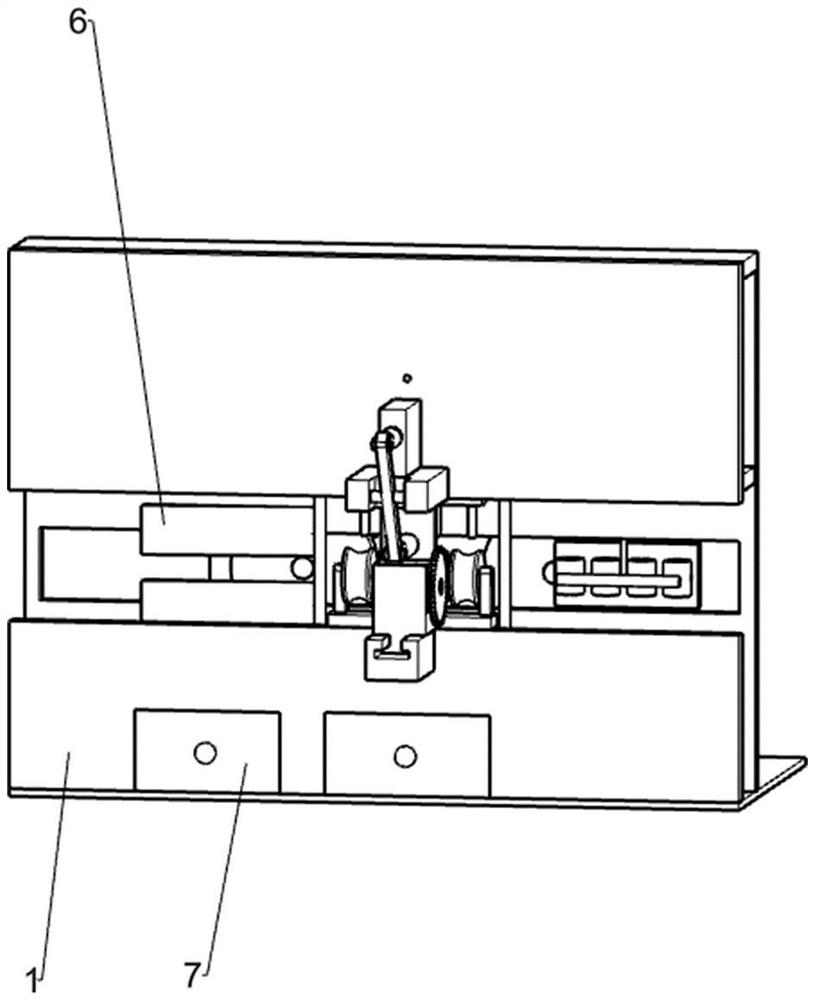

[0084] A plastic pipe fitting burr cutting and polishing device that cooperates with knife cutting and polishing, such as Figure 1-10 Shown, comprise the first support 1, power mechanism, feeding mechanism, cutting mechanism, wedge-shaped block 6 and feed box 7, the front and rear sides of the first support 1 middle position are provided with the chute of left and right direction, and power mechanism is fixedly installed on the second The middle position of the rear side of a bracket 1, the feeding mechanism is fixedly connected with the power mechanism, the feeding mechanism is slidably installed in the chute provided on the rear side of the first bracket 1, the cutting mechanism is installed at the inner middle position of the first bracket 1, the cutting mechanism and The power mechanism is connected, and the two wedge blocks 6 are fixedly installed on the upper and lower sides of the chute provided on the rear side of the first bracket 1; the two material boxes 7 are fixed...

Embodiment 2

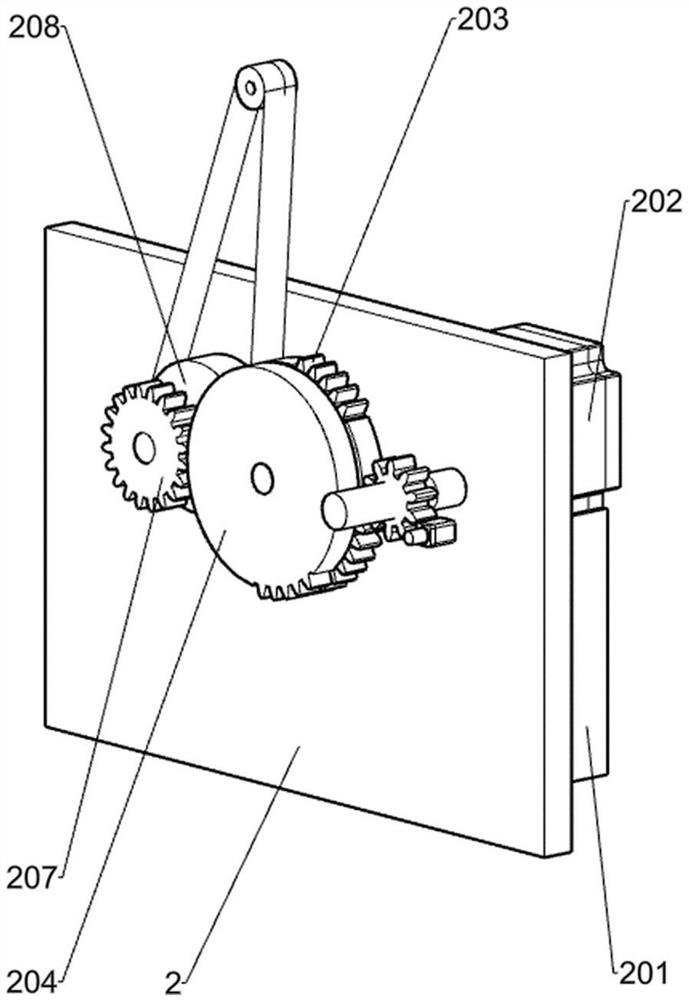

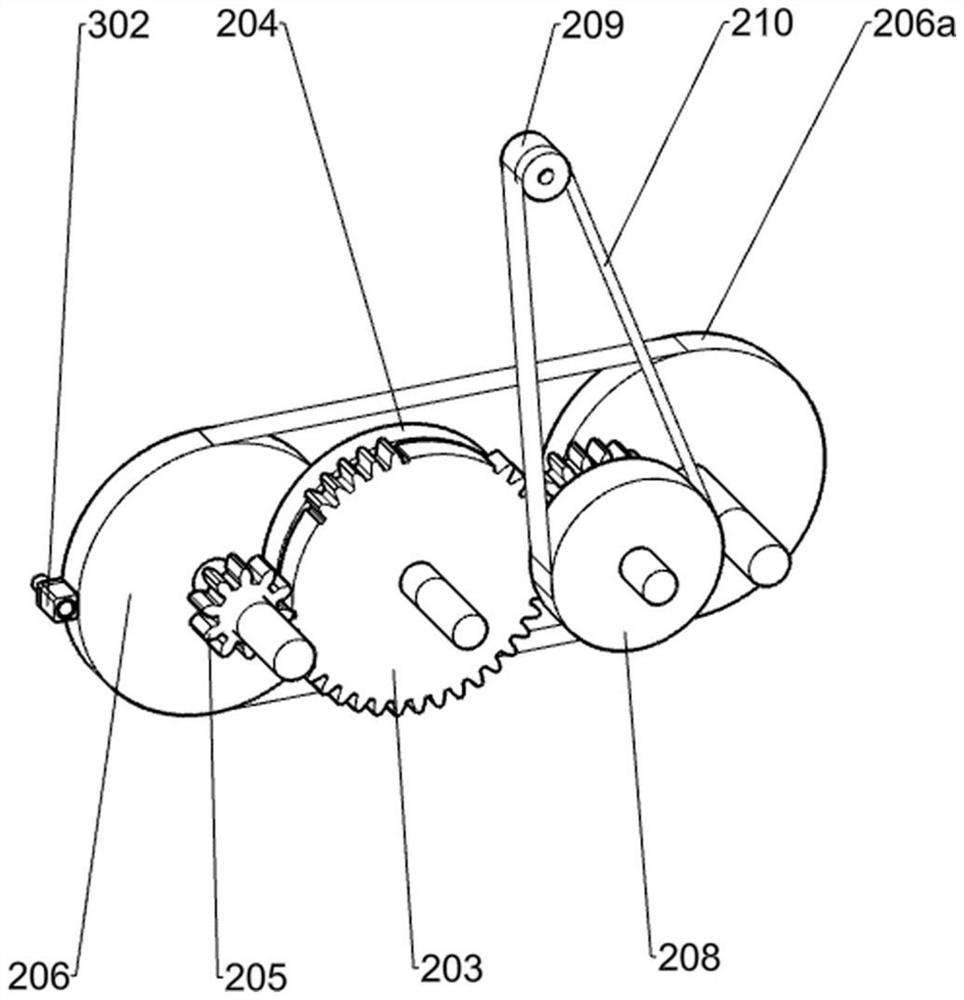

[0087] On the basis of Embodiment 1, a plastic pipe fitting burr cutting and polishing device that matches knife shearing and polishing, such as Figure 2-3 As shown, the power mechanism includes a first support plate 2, a support platform 201, a first motor 202, a first tooth-less gear 203, a second tooth-less gear 204, a first pulley 206, a first straight gear 205, a first Belt 206a, the second pulley 208, the second spur gear 207, the third pulley 209 and the second belt 210, the first support plate 2 is fixedly installed in the rear middle position of the first support 1, and the support table 201 is fixedly installed in the The rear middle position of the first bracket 1, the support platform 201 is located at the rear side of the first support plate 2, the body of the first motor 202 is fixedly installed on the upper part of the support platform 201, and the teeth pattern of the first tooth-missing gear 203 is divided into two parts, The tooth pattern with a larger area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com