Equipment power distribution control box

A technology for power distribution control and equipment, applied in seismic equipment, electrical components, substation/switch layout details, etc., can solve problems such as weak concentrated load capacity, slag cracking signal interference and fluctuation, and small thickness of cold-rolled formed steel walls. Achieve the effect of reducing the impact force of installation, good operation signal and increasing load force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

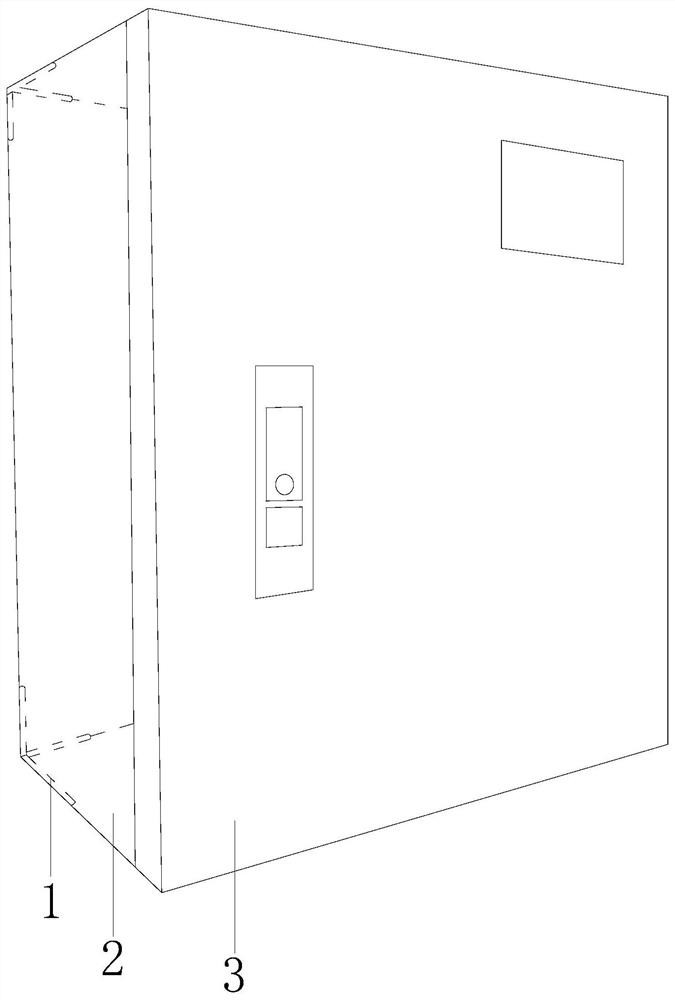

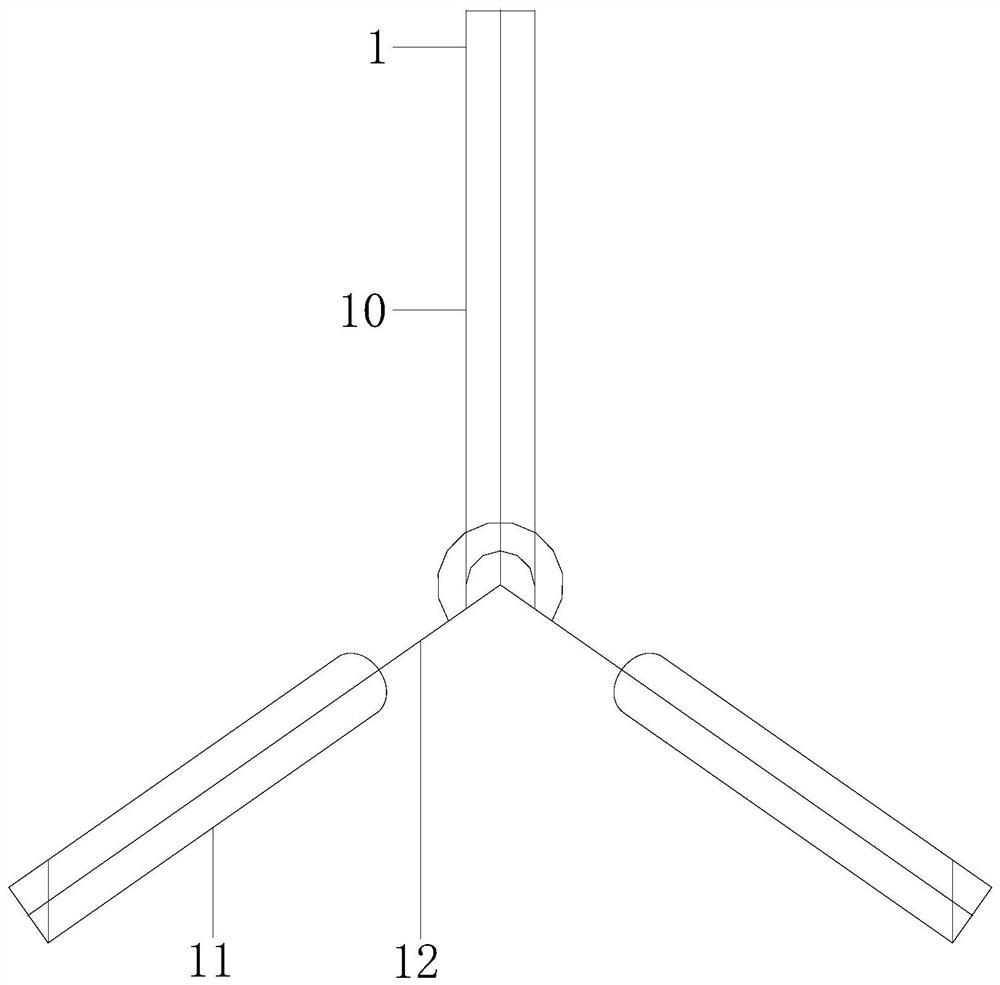

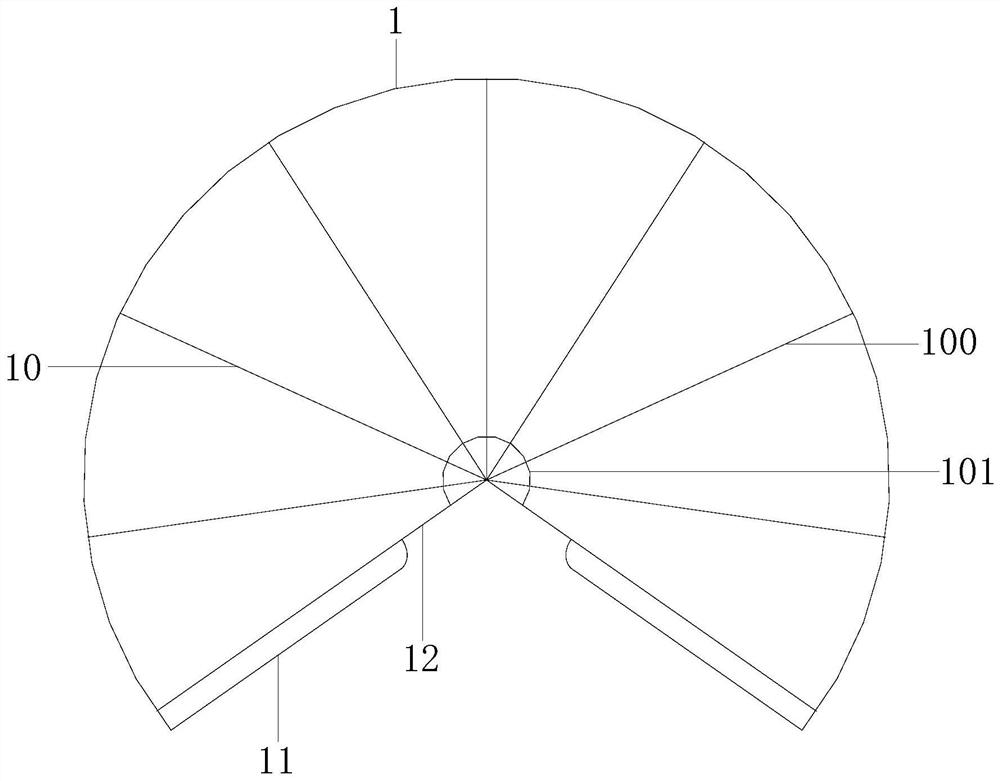

[0027] Example 1 see Figure 1-6 , the present invention provides a technical scheme of equipment power distribution control box: its structure includes an inner angle structure 1, a control box frame 2, and a control box door 3, the inner angle structure 1 is installed inside the control box frame 2, and the element The device is installed inside the control box frame 2, and is driven and assisted by the inner angle structure 1. The control box frame 2 and the control box door 3 are connected by shaft bolts. The inner angle structure 1 is composed of an upper rod structure 10, a side branch structure 11. Composed of tripod bars 12. When the inner angle structure 1 is driven, the upper rod structure 10 is unfolded in a fan-shaped structure, which increases the thickness of the corners of the control box frame 2. The upper rod structure 10 and the side branch structure 11 are installed on the On the tripod bar 12, the upper rod structure 10 includes a movable rod 100 and a mova...

Embodiment 2

[0029] Example 2 see Figure 7 , 8 , the present invention provides a technical solution for equipment power distribution control box: the structure of the side support structure 11 includes an end pad 110, a main part structure 111, and a fan pressure structure 112, and the end pad 110 is bonded to the main part structure 111, The main part structure 111 is track-connected with the fan pressing structure 112. The main part structure 111 includes an integral main part 1110, an upper sliding part 1111, and a bottom sliding rail 1112. The integral main part 1110 is embedded with a bottom sliding rail 1112. The upper slider 1111 is track-connected with the bottom slide rail 1112. The fan pressure structure 112 includes a sectioned inclined support plate 1120, a pressure section cone block 1121, and a circular pad 1122. The sectioned inclined support plate 1120 and the section pressure cone The block 1121 is installed and connected, the section pressure cone block 1121 is glued t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com