Method for rolling metal clad plate through double crossed corrugated rollers

A metal clad plate and cross-corrugation technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of low bonding strength, warpage and edge cracking of metal clad plates, reduce requirements and improve bonding Strength, the effect of avoiding edge cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

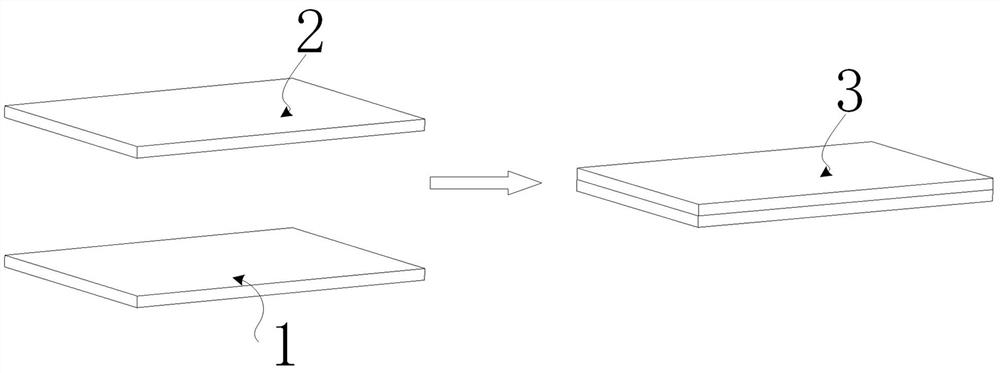

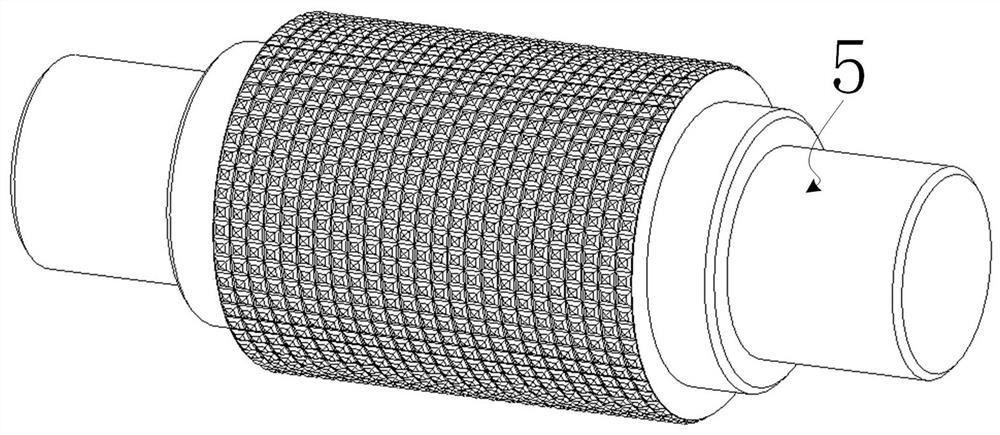

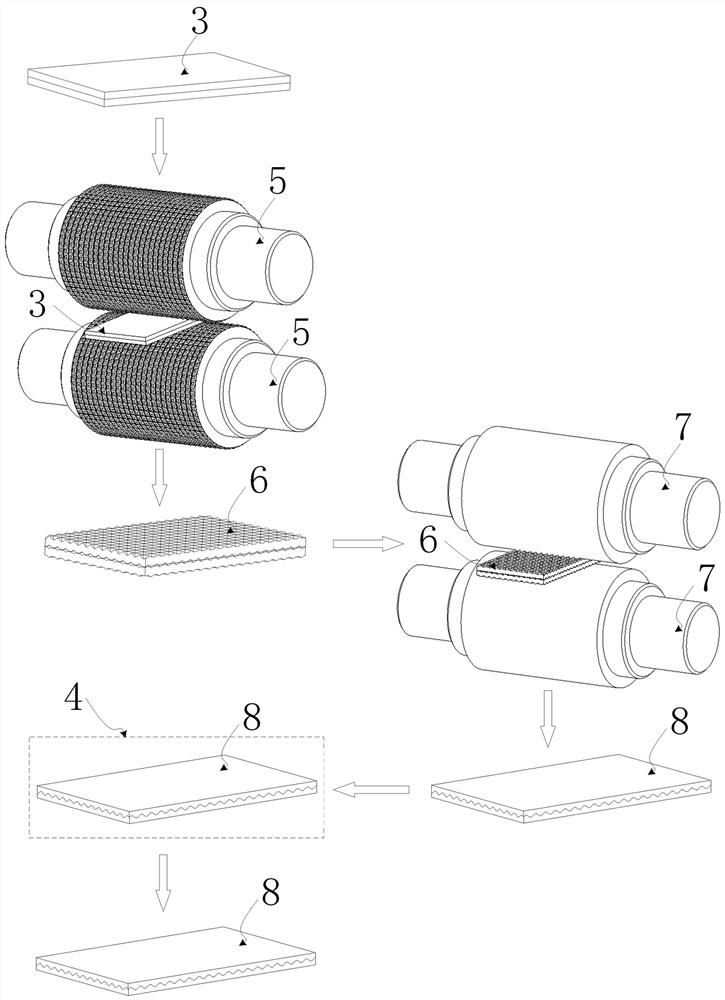

[0027] refer to Figure 1-6 , a method for rolling a Mg / Al composite plate with double cross corrugated rolls, comprising the following steps:

[0028] S1. Blank making: Select 5052 aluminum alloy plate with relatively small deformation resistance as the base plate 1, the length, width and height are 100 mm, 50 mm, and 2 mm respectively, and select the AZ31 brand magnesium alloy plate with relatively large deformation resistance as the double plate 2. The width and height are 100mm, 50mm, and 2mm respectively. Use a wire brush to polish the surface of the base plate and the double plate to be bonded to remove the surface oxide layer and pollutants. Stack the two plates on the surface to be compounded and fix them at the edges. The metal composite board slab is obtained; here the substrate 1 and the cladding board 2 can be fixed by common methods such as riveting.

[0029] S2, one-pass rolling: the metal composite plate slab 3 prepared in step S1 is first put into the heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com