PCB board-mounted resistor with polygonal cross-section and its forming process

A PCB board and molding process technology, applied in the field of PCB on-board resistors and their molding processes, can solve the problems of resistance row density and performance impact, poor resistance consistency and stability, and low resistance edge resolution. Regularity and controllability, improving consistency and stability, preserving the effect of appearance integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

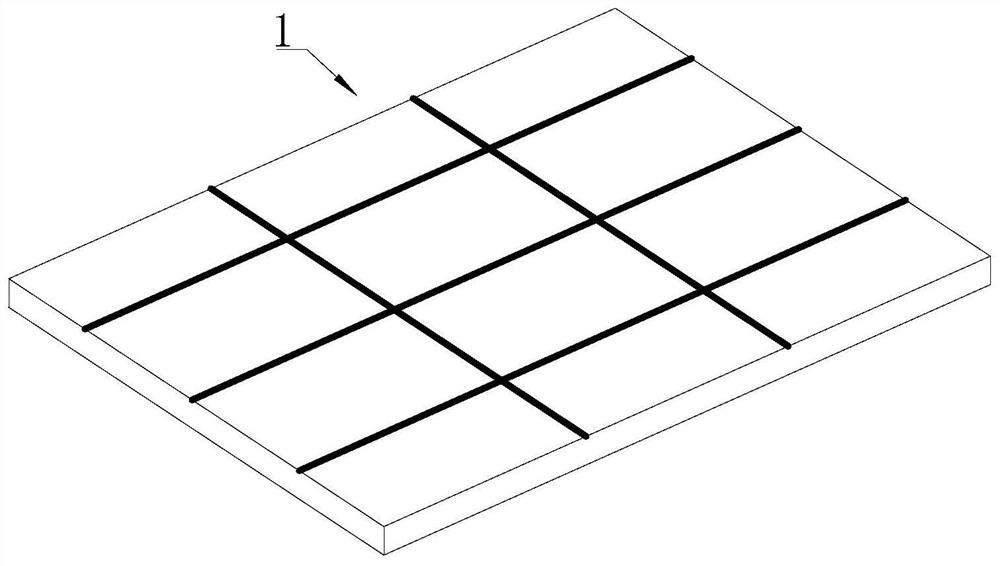

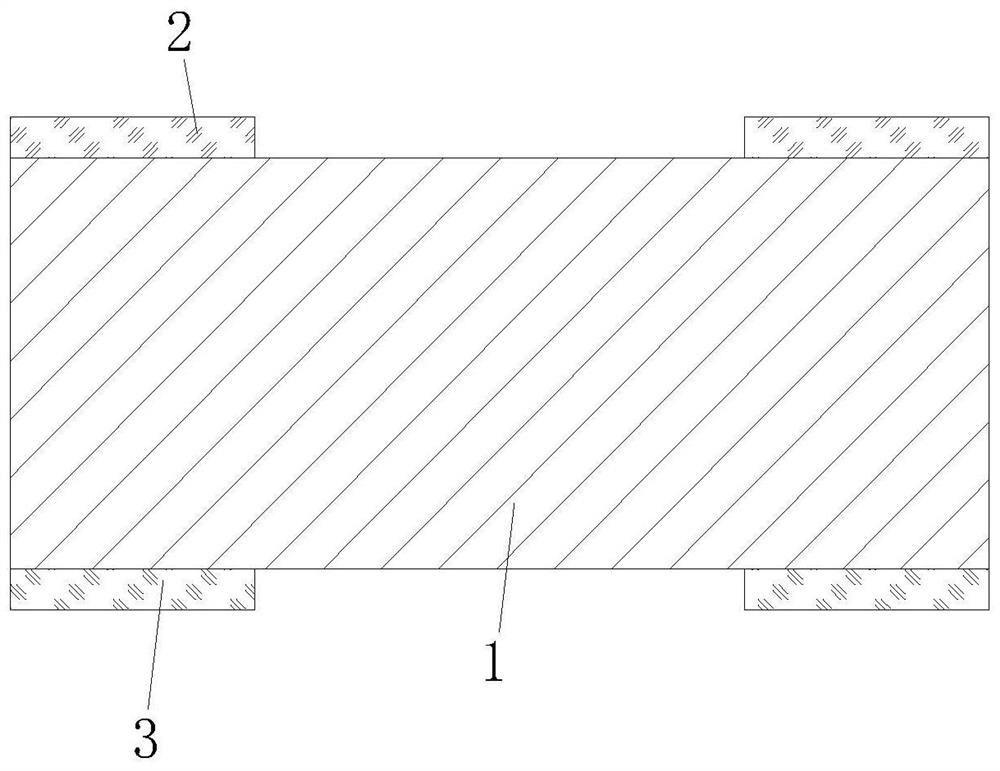

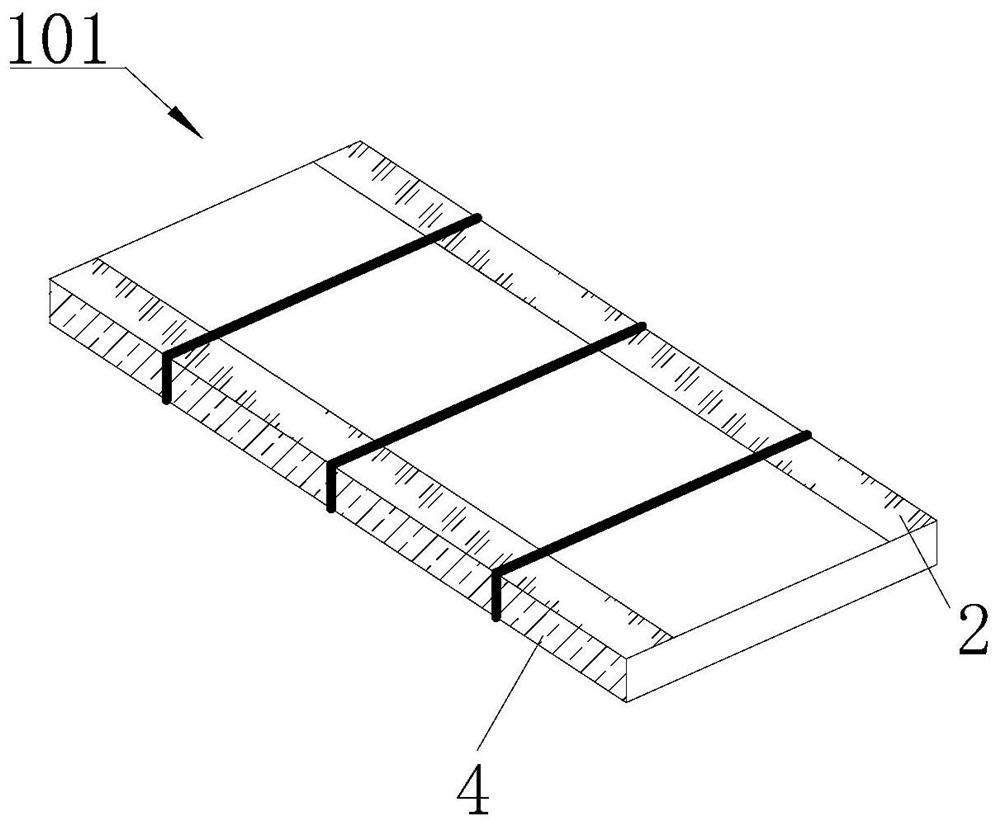

[0052] Specific embodiment 1: please refer to Figure 1-11 , including the following steps:

[0053] A. Provide a base plate 1. The upper and lower end surfaces of the base plate 1 are provided with a plurality of transverse folding block lines and a plurality of longitudinal folding lines. The polylines and polyblocks are crisscrossed to form multiple grids. The position of the fold line on the lower end face corresponds to the position of the fold line on the upper end face. The grid areas on the upper end face correspond one-to-one with the grid areas on the lower end face. The position of the folded block line on the lower end face corresponds to the position of the folded block line on the upper end face.

[0054] B. The electrode paste is printed on the substrate 1 by screen printing on the upper end surface of the substrate 1 , and the front electrode 2 is formed after drying and sintering. There are two front electrodes 2 in each grid area. The two front electrode...

specific Embodiment 2

[0065] Specific embodiment 2: different from specific embodiment 1, please refer to Figure 12-13 , the cross section of the resistance core 6 is T-shaped, and the outer side of the resistance core 6 is attached to the inner end and part of the upper end of the front electrode 2, so that the cross section of the finally formed resistance layer 6 is also T-shaped, effectively ensuring resistance The connection area between the layer 6 and the front electrode can effectively prevent the PCB resistance from being disconnected from the front electrode 2 due to the bending of the resistance layer 6 between the two front electrodes 2 after the expansion of heat and heat.

specific Embodiment 3

[0066] Specific embodiment 3: Different from the specific embodiment 1, the resistance core 6 and the resistance mold 7 are both sintered from sodium chloride solid, and the sintered core and the mold 7 are polished by laser to control the shape and the inner cavity. flatness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com