Manufacturing method of transparent glass light guide plate

A technology of transparent glass and a production method, applied in the field of light guide plates, can solve the problems of dot cracks, glass breakage, influence on glass strength and product quality, etc., and achieve the effects of high transmittance, convenient processing, and simple production steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

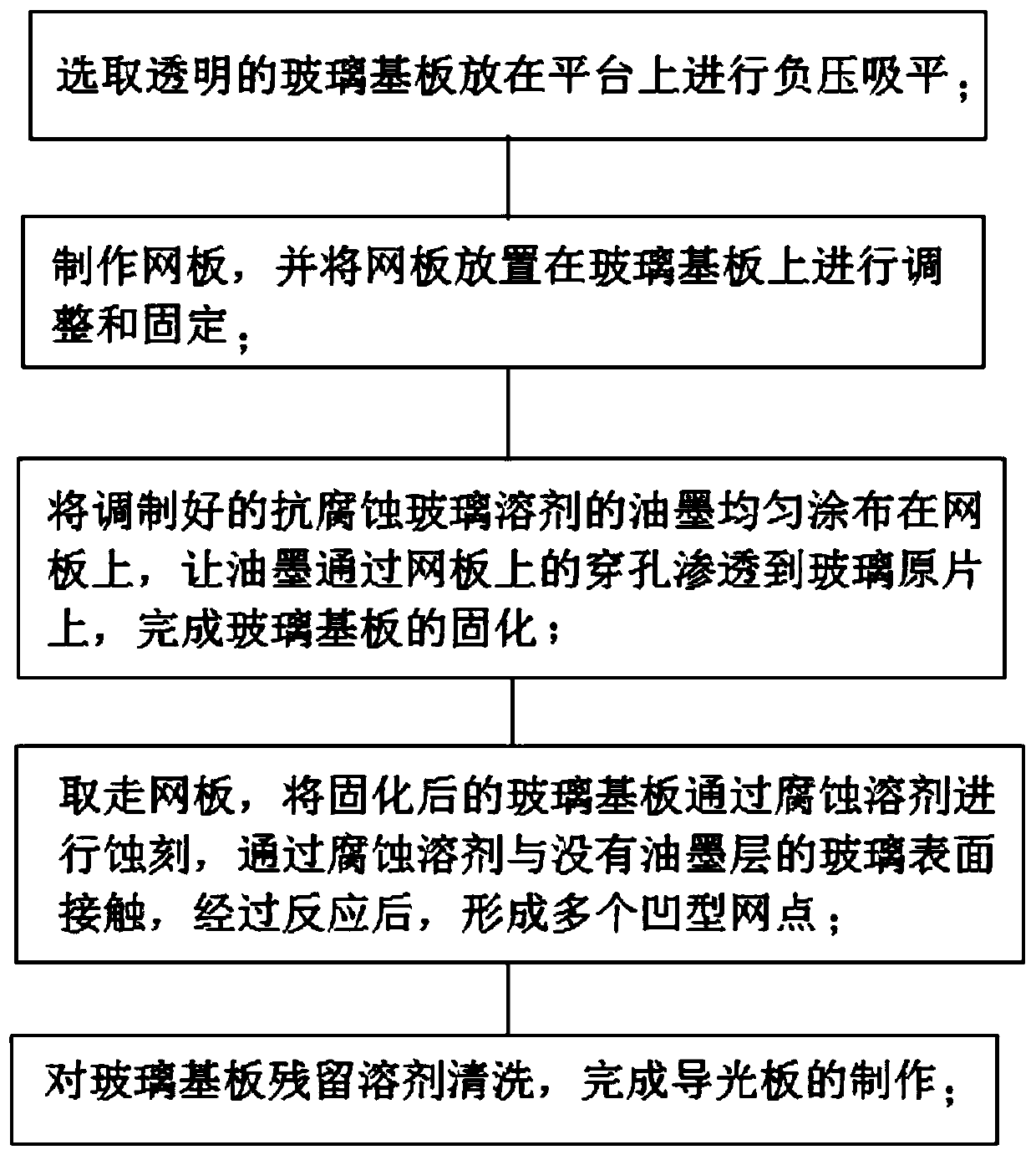

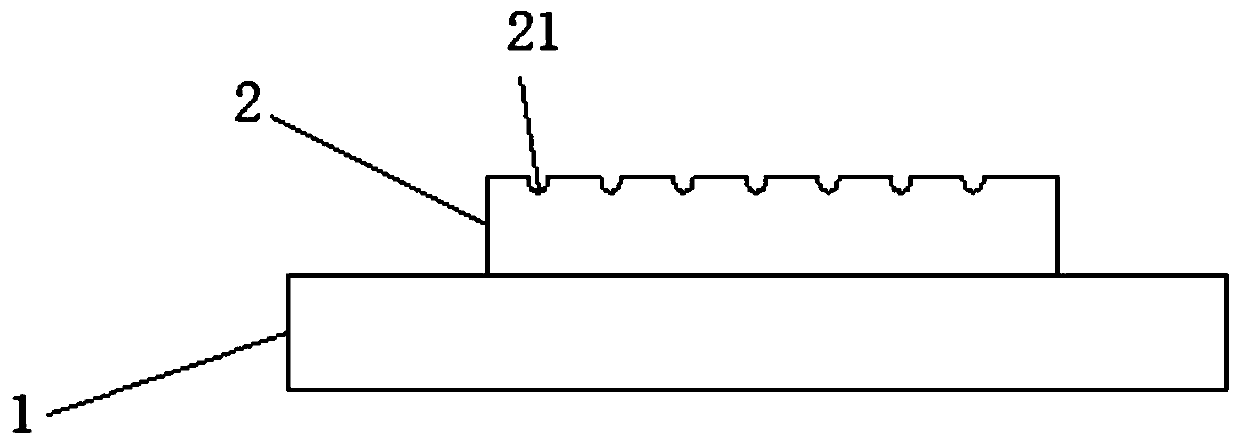

[0023] The manufacturing method of the glass light guide plate of this embodiment includes the following sequential steps:

[0024] (1) Select a transparent glass substrate 2 and place it on the platform 1 for negative pressure suction leveling;

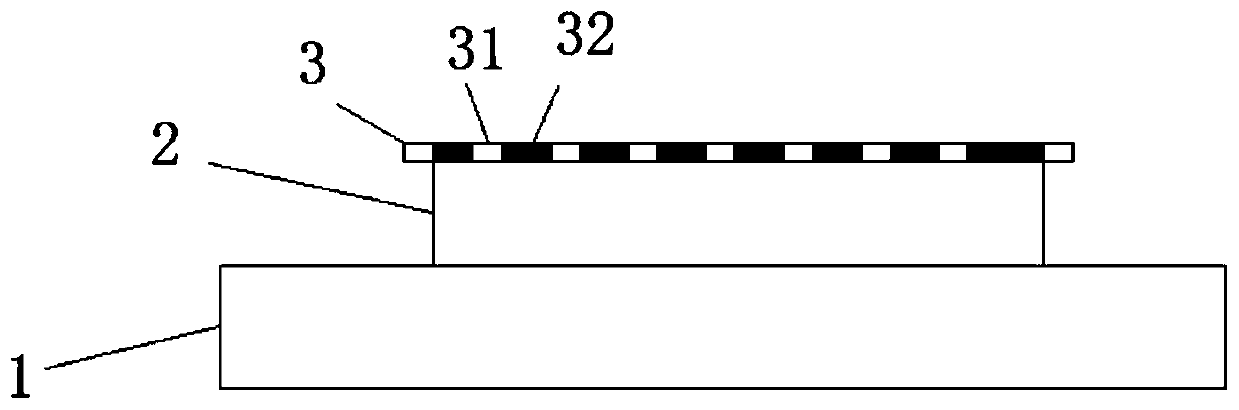

[0025] (2) making a screen, and placing the screen 3 on the glass substrate 2 for adjustment and fixing;

[0026] (3) Evenly apply the prepared anti-corrosion glass solvent polyvinyl chloride solvent on the screen 3, so that the polyvinyl chloride solvent penetrates into the original glass sheet through the perforation 31 on the screen 3, and completes the curing of the glass substrate 2;

[0027] The making of the screen plate 3 specifically includes the following steps: selecting a substrate and the substrate is not smaller than the glass substrate 2; according to the distribution of dots on the glass substrate 2, opening holes 31 are made on the substrate, and the positions of the openings 31 are consistent with those outside the ...

Embodiment 2

[0032] The manufacturing method of the glass light guide plate of this embodiment includes the following sequential steps:

[0033] (1) Select a transparent glass substrate 2 and place it on the platform 1 for negative pressure suction leveling;

[0034] (2) making a screen, and placing the screen 3 on the glass substrate 2 for adjustment and fixing;

[0035] (3) Evenly coat the prepared anti-corrosion glass solvent styrene on the screen 3, so that the styrene solvent penetrates into the original glass sheet through the perforation 31 on the screen 3, and complete the curing of the glass substrate 2;

[0036] The making of the screen plate 3 specifically includes the following steps: selecting a substrate and the substrate is not smaller than the glass substrate 2; according to the distribution of dots on the glass substrate 2, opening holes 31 are made on the substrate, and the positions of the openings 31 are consistent with those outside the mesh. The positions are corresp...

Embodiment 3

[0041] The manufacturing method of the glass light guide plate of this embodiment includes the following sequential steps:

[0042] (1) Select a transparent glass substrate 2 and place it on the platform 1 for negative pressure suction leveling;

[0043] (2) making a screen, and placing the screen 3 on the glass substrate 2 for adjustment and fixing;

[0044] (3) Uniformly coat the prepared anti-corrosion glass solvent polyethylene on the screen plate 3, so that the polyethylene solvent penetrates into the original glass sheet through the perforation 31 on the screen plate 3, and complete the curing of the glass substrate 2;

[0045] The making of the screen plate 3 specifically includes the following steps: selecting a substrate and the substrate is not smaller than the glass substrate 2; according to the distribution of dots on the glass substrate 2, opening holes 31 are made on the substrate, and the positions of the openings 31 are consistent with those outside the mesh. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com