Full-continuous rolling production process for magnesium alloy plate

A production process, magnesium alloy plate technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of low plasticity of magnesium alloys, poor formability and poor plasticity of rolled plates, and achieve short preparation process and good forming High durability, avoid edge cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

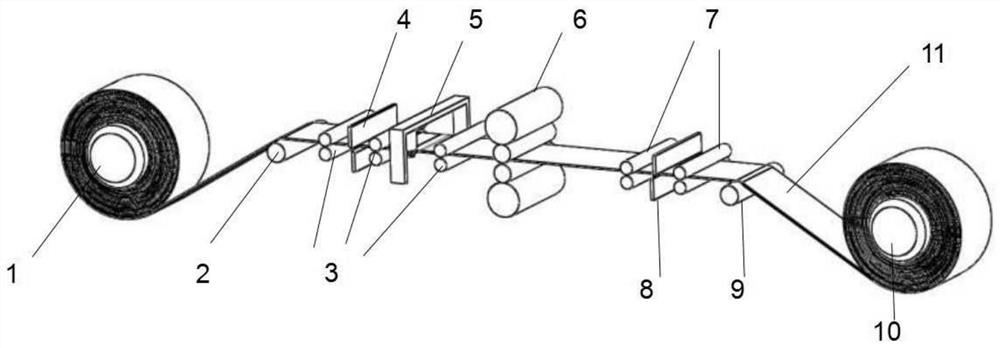

Image

Examples

Embodiment 1-7

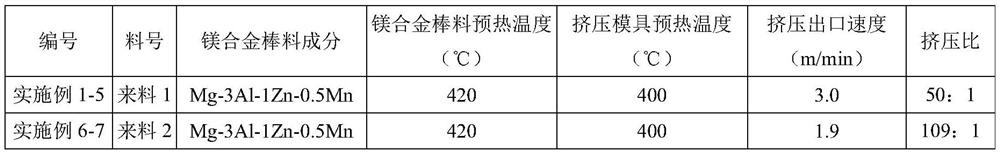

[0083] In Examples 1-7 of the present invention, the preparation of continuous feed (magnesium alloy extrudate rolls) is carried out in accordance with two different extrusion processes, and the processed process parameters and various performance results are obtained. Table 1-1, shown in Table 1-2.

[0084] Table 1-1 lists alloy components and related manufacturing process parameters of two consecutive rolling materials.

[0085] Table 1-1.

[0086]

[0087] The two continuous rolling materials obtained were respectively observed and various performance tests, and the resulting observations and test results were listed in Table 1-2.

[0088] Table 1-2 lists the performance test results of two consecutive rolling materials.

[0089] Table 1-2.

[0090]

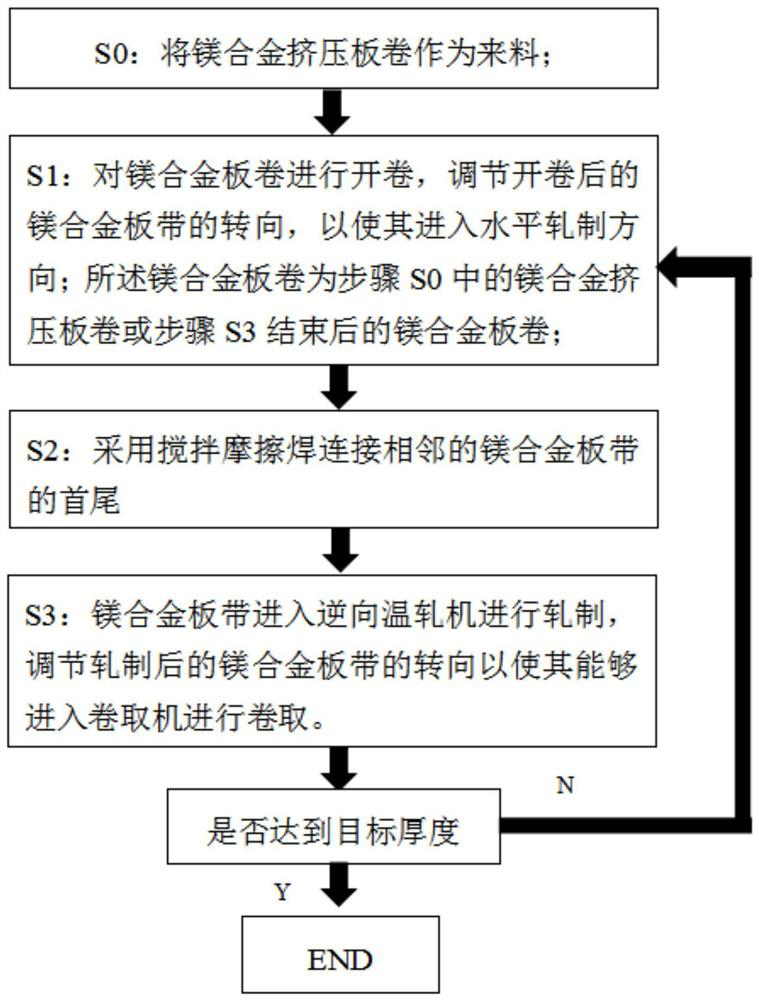

[0091] The two materials used above are used. figure 2 The steps shown are made to produce a magnesium alloy sheet, forming the first examples of the following description.

[0092] Table 2 lists Examples 1-7 figure 2 The key ...

Embodiment 1

[0097] Step 1: The corresponding magnesium alloy extruder roll corresponding to Table 1-2 described above is supplied.

[0098] Step 2: Follow the magnesium alloy extrusion plate, install the tension roller downstream of the unwinding machine, adjust the amount of plate of the sheet, adjust the sheet of the plate, so that the open / rolling tension = slate cross-sectional area × sheet yield The intensity is 10% -30%. In the present embodiment, the rolling speed is controlled in the magnesium alloy sheet rolling process, and the opening speed is 20 m / min. At this time, the rolling tension is 2.0KN = slate cross-sectional area × slave yield strength 20%. The scroll is made of heat-inspiring mode in the furnace, which is heated in the furnace, the temperature is 150 ° C, control the heating time of 15 min, adjust the steering of the magnesium alloy sheet after the open removal to enable it to enter the level The direction of rolling, and the retrograde temperature rolling is entere...

Embodiment 2

[0105] In the present embodiment, the target magnesium plate thicknesses of Example 2 were the same as in Example 1, and the same temperature rolling steps as in Example 1 were implemented.

[0106] In the present embodiment, the step of Example 2 is substantially the step 1 to 7 of the first embodiment. However, it is to be noted that in fact, in Example 1, the process parameters designated in step 2 and step 3 are as follows:

[0107] Step 1: The corresponding magnesium alloy extruder roll corresponding to Table 1-2 described above is supplied.

[0108]Step 2: Follow the magnesium alloy extrusion plate, install the tension roller downstream of the unwinding machine, adjust the amount of plate of the sheet, adjust the sheet of the plate, so that the open / rolling tension = slate cross-sectional area × sheet yield The intensity is 10% -30%. In the present embodiment, the rolling speed is controlled in the magnesium alloy sheet rolling process, and the opening speed is 20 m / min....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com