Rolling and pickling process of wide zirconium plate

A zirconium plate and pickling technology, which is applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as unstable product quality, uneven slab temperature, and significant work hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

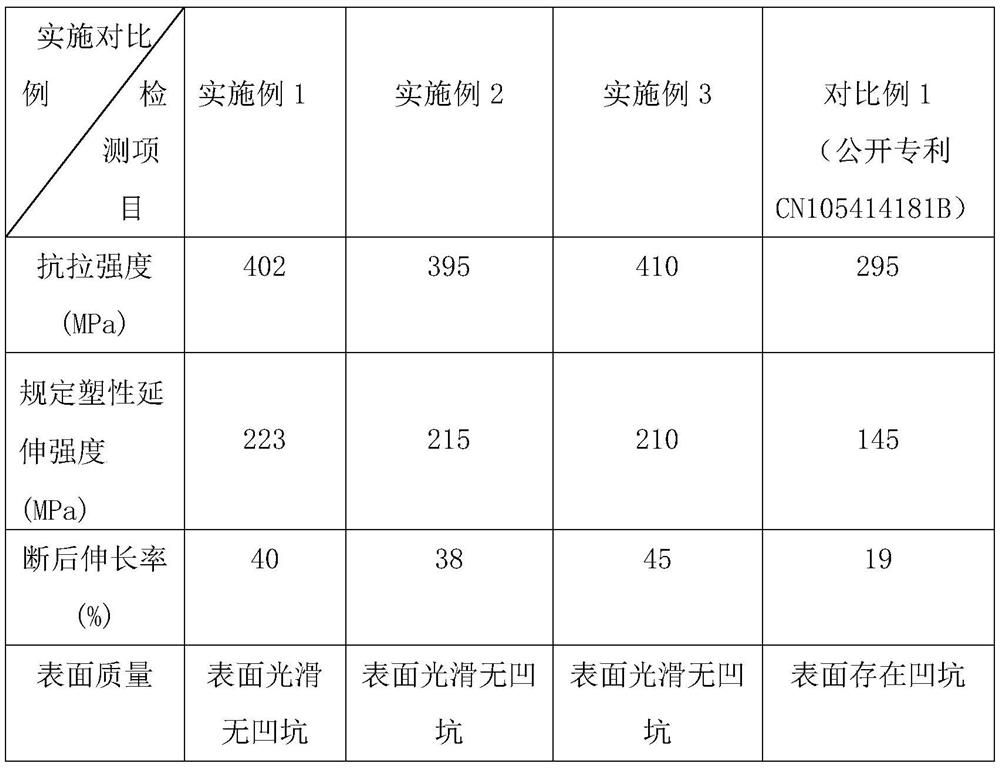

Examples

Embodiment 1

[0024] A rolling and pickling process for wide-width zirconium plates, using a slab thickness of 160-260mm, the thickness of the slab after rolling is 3-5mm, the heating furnace adopts a continuous walking heating furnace, and the furnace pressure in the heating furnace is controlled At 10-15Pa;

[0025] Include the following steps:

[0026] Step 1. Slab heating: Put the zirconium plate slab into the heating furnace. The temperature of the first heating section is controlled at 780°C-870°C for 40 minutes. After the first heating section is completed, it enters the second heating section, and the temperature of the second heating section is controlled at 890°C. ~910℃, time 55min, enter the soaking section after the end of the second heating section, the temperature of the soaking section is controlled at 920℃~940℃, the time is 40min, the total heating time in the furnace is controlled at 135min, the residual oxygen in each section of the heating furnace ≤2%;

[0027] Step 2. ...

Embodiment 2

[0037] Compared with embodiment 1, the difference is:

[0038] Step 1. Slab heating: put the zirconium slab into the heating furnace, the temperature of the first heating section is controlled at 780°C to 870°C, and the time is 50min. After the first heating section is completed, enter the second heating section, and the temperature of the second heating section is controlled at 890°C ~910℃, time 60min, enter the soaking section after the end of the second heating section, the temperature of the soaking section is controlled at 920℃~940℃, the time is 50min, the total heating time in the furnace is controlled at 160min, the residual oxygen in each section of the heating furnace ≤2%;

[0039] Step 2, slab rough rolling: the rough rolling mill adopts a circular reversible rolling mill, the rough rolling adopts 7 passes of rolling, the 1st, 3rd, and 5th passes are descaled, the descaling speed is 1.5-2.0m / s, and the rough rolling inlet temperature is 910 ℃~930℃, rough rolling outle...

Embodiment 3

[0044] Compared with embodiment 1, the difference is:

[0045] Step 1. Slab heating: Put the zirconium plate slab into the heating furnace. The temperature of the first heating section is controlled at 780 ° C ~ 870 ° C for 55 minutes. After the first heating section is completed, enter the second heating section, and the temperature of the second heating section is controlled at 890 ° C. ~910℃, time 70min, enter the soaking section after the end of the second heating section, the temperature of the soaking section is controlled at 920℃~940℃, the time is 55min, the total heating time in the furnace is controlled at 180min, the residual oxygen in each section of the heating furnace ≤2%;

[0046] Step 2, slab rough rolling: the rough rolling mill adopts a circular reversible rolling mill, the rough rolling adopts 7 passes of rolling, the 1st, 3rd, and 5th passes are descaled, the descaling speed is 1.5-2.0m / s, and the rough rolling inlet temperature is 910 ℃~930℃, rough rolling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com