Severe plastic deformation method and severe plastic deformation device for pressing and rolling corner of non-equivalent passage

A technology of equal channel corners and non-equal channel channels, applied in the field of channel corner extrusion drastic plastic deformation method and its device, can solve the problems of poor material stress state, limit of total strain, material strength decrease, etc., and achieve good stress state, The effect of low manufacturing cost and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

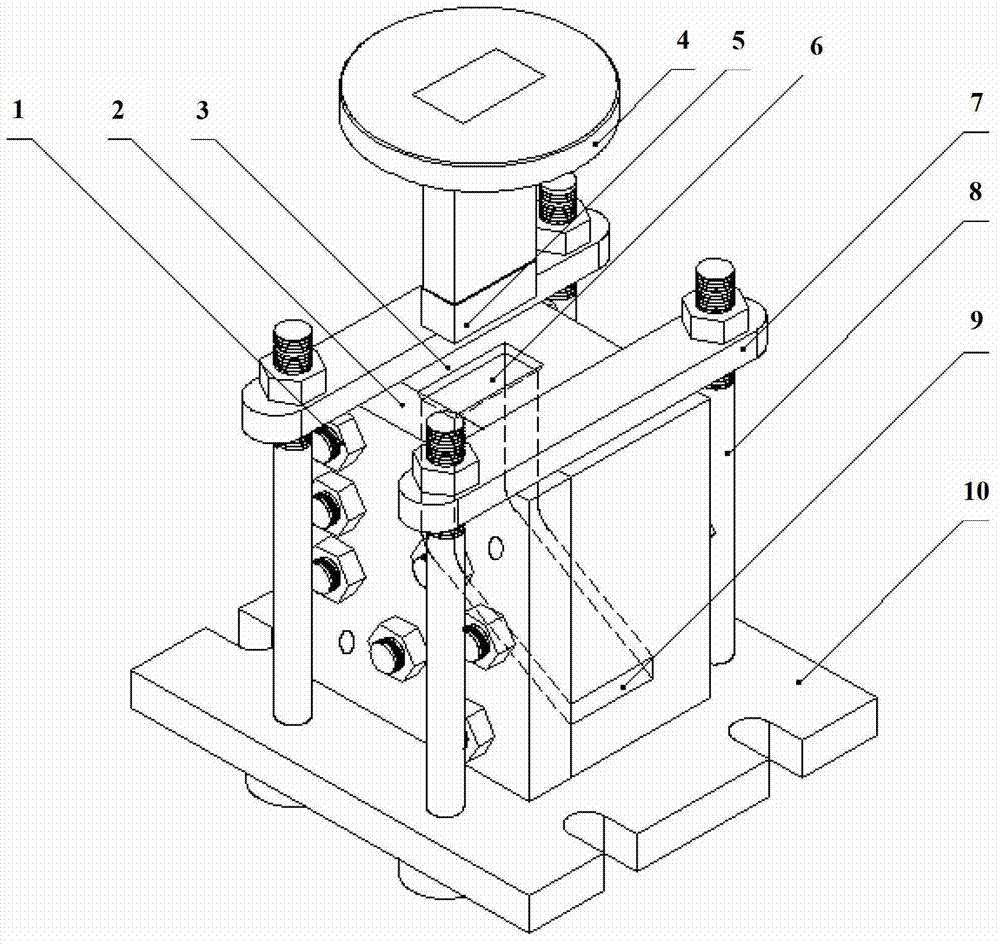

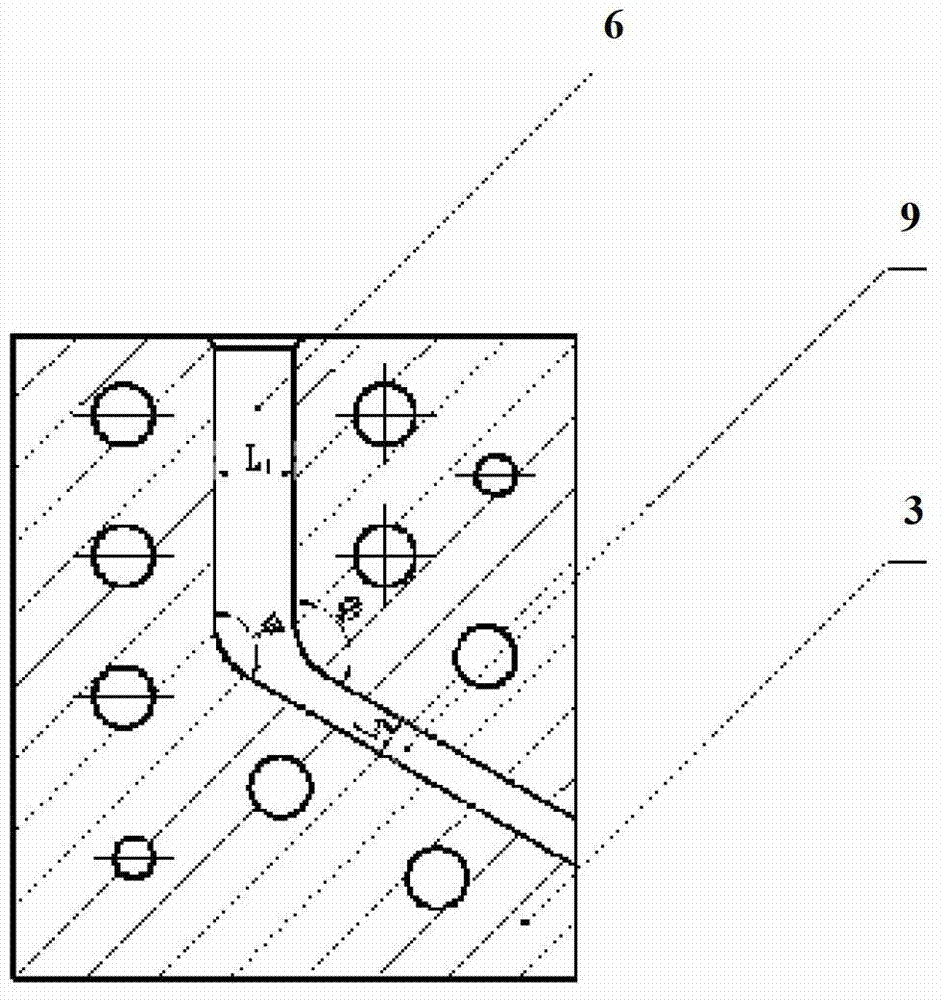

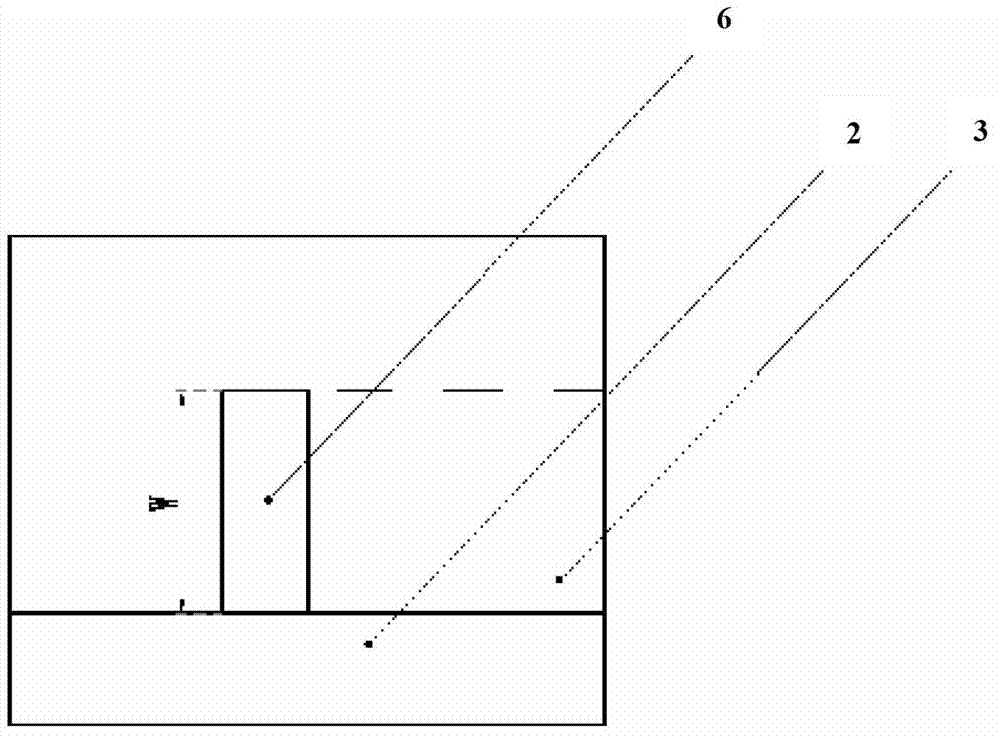

[0027] The non-equal-channel angular extrusion and acute plastic deformation method of the present invention integrates the equal-channel angular extrusion technology and the cumulative stacking rolling technology, and specially designs a non-equal-channel angular extrusion method for realizing the non-equal-channel angular extrusion rapid plastic deformation method Hyperplastic deformation devices, such as figure 1 shown. The mold part of the device is as figure 2 , 3 As shown, the non-equal channel means that the mold of the device is provided with two intersecting and non-equal cross-section I channel 6 and II channel 9, I channel 6 is perpendicular to the upper end surface of the mold, and II channel 9 and I channel 6 form a clamp Angle, the inner angle of the channel Φ=90°, the outer angle Ψ=0°. The width W of the I channel 6 and the II channel 9 is the same, W is 50 mm, and the thickness L of the I channel 6 1 Thickness L greater than II channel 9 2 , and L 1 for ...

Embodiment 2

[0038] The materials used in this embodiment are the same as in Embodiment 1, and the structural parameters of the mold part of the non-equal channel angle extrusion device are selected as follows: L 1 / L 2 =2, L 1=20mm, channel inner angle Φ=120°, outer angle Ψ=30°, the non-equal channel angular rolling acute plastic deformation device is the same as that of embodiment 1 except for the structural parameters of the above-mentioned mold part. The specific steps and process conditions of the rapid plastic deformation method of non-equal channel angular extrusion of Mg-Li-Al alloy plates are the same as in Example 1, and the mechanical properties of the material obtained in this example after completing multi-pass extrusion deformation are shown in Table 2. .

[0039] Table 2

[0040]

Embodiment 3

[0042] The materials used in this embodiment are the same as in Embodiment 1, and the structural parameters of the mold part of the non-equal channel angle extrusion device are selected as follows: L 1 / L 2 =4, L 1 = 20mm, channel inner angle Φ = 160°, outer angle Ψ = 45°, non-equal channel angular extrusion and rapid plastic deformation device is the same as that of embodiment 1 except for the structural parameters of the above-mentioned mold part.

[0043] Except for the following parameters, the specific steps and process conditions of the method for the rapid plastic deformation of the non-equal channel angular extrusion of the Mg-Li-Al alloy plate are the same as in Example 1:

[0044] After the Mg-Li-Al alloy plate is deformed one by one, it is cut into L along the length direction. 1 / L 2 = 4 parts were stacked along the thickness direction and placed in channel I 6, the above steps were repeated, and the mechanical properties of the material obtained in this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com