Non-oriented high silicon steel sheet containing boron and zirconium and preparation method thereof

A high-silicon steel and sheet technology, applied in the field of steel rolling, can solve the problems of high-silicon steel with high deformation resistance, restricting application and development, and producing thin strips or sheets, and achieves the effect of refining grains, low load, and inhibiting nucleation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

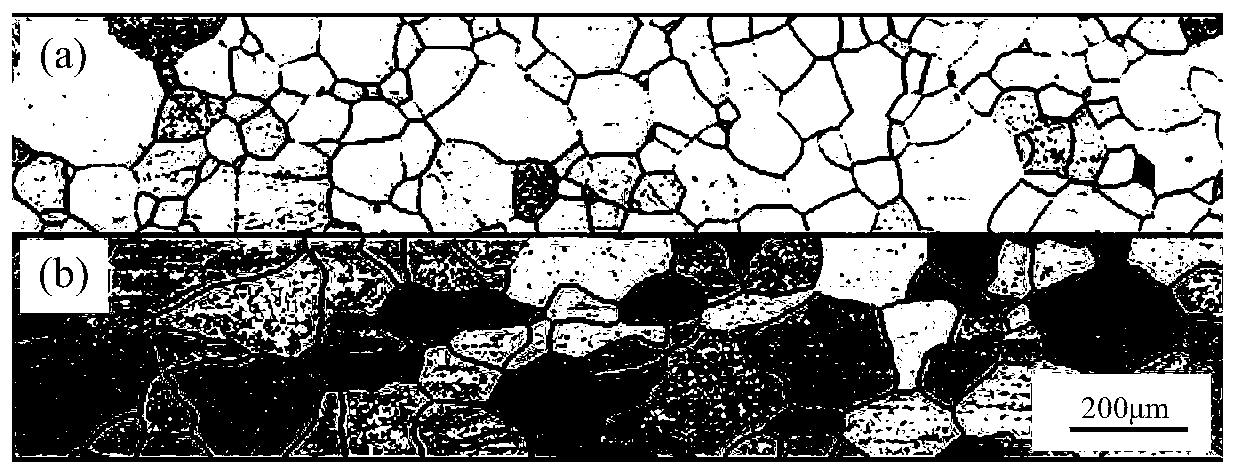

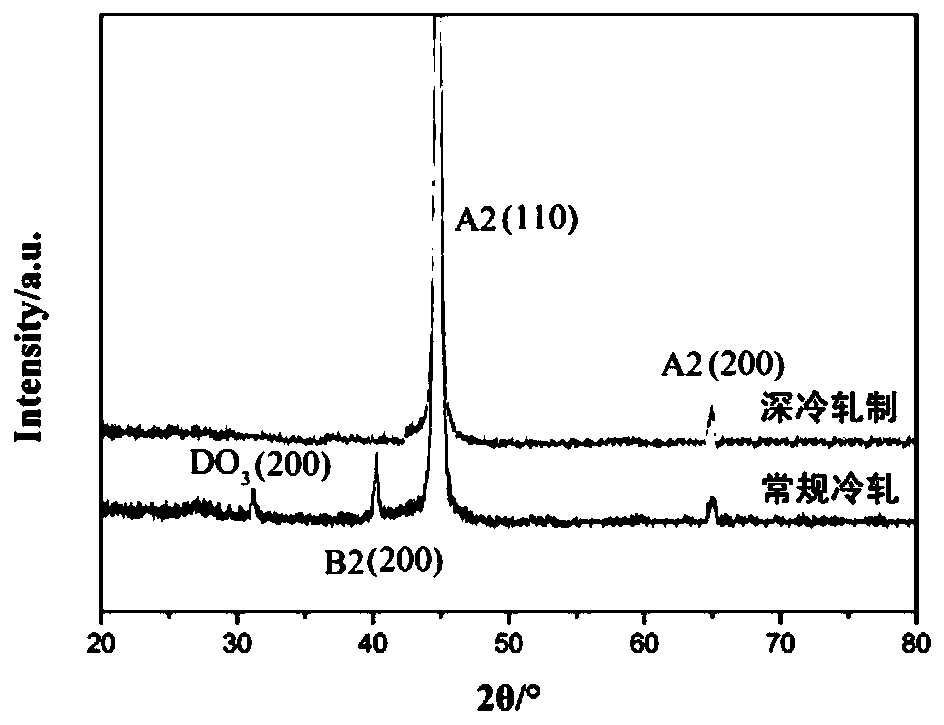

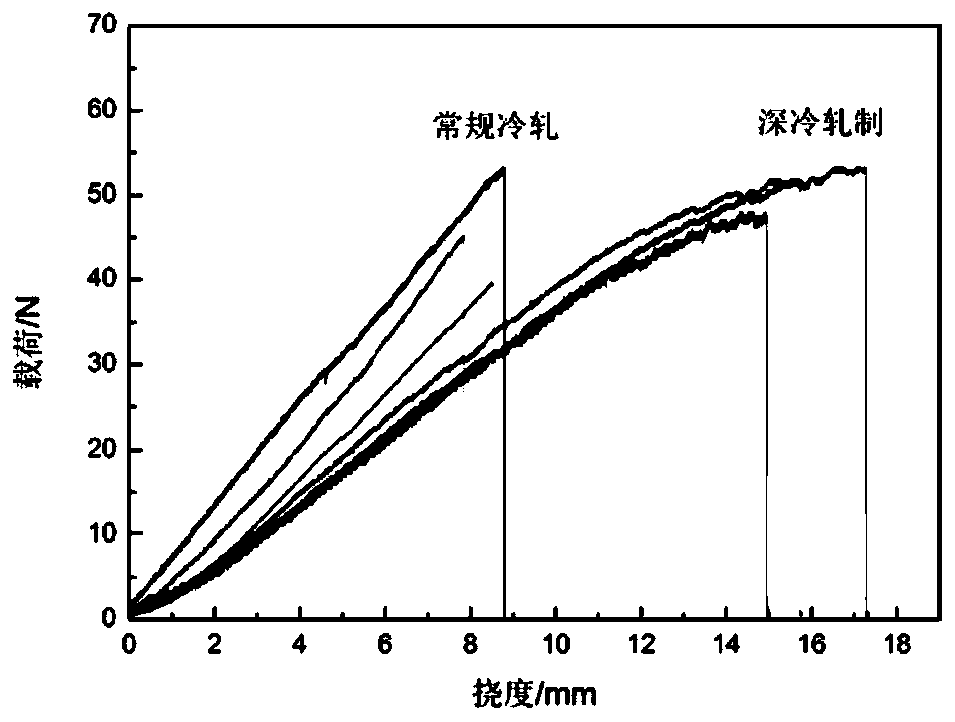

[0031] Vacuum induction furnace is used to cast high-silicon steel ingots, and its chemical composition by weight percentage is: Si 4.5%, B0.03%, Zr 0.04%, C 0.008%, Mn 0.009%, P 0.005%, S 0.004%, N 0.002 %, O0.002%, balance Fe. At a temperature of 1180°C, after 220 minutes of heat preservation, air free forging was used to form a 50mm thick billet. The heating temperature of the slab hot rolling is 1150°C, and the holding time is 110min. After the heat preservation, the non-lubricated hot rolling is carried out on a two-roll reversible experimental hot rolling mill and hot rolled to 3.5mm by 10 passes. The rolling start temperature is 1100°C. The final rolling temperature was 870°C, and then cooled to room temperature in air. Use 5% hydrochloric acid solution to pickle the hot-rolled plate, the pickling temperature is 50° C., and the pickling time is 10 minutes to remove the surface oxide scale.

[0032] Warm rolling is carried out by using a four-roll cold rolling mill, an...

Embodiment 2

[0036] Vacuum induction furnace is used to cast high-silicon steel ingots, and its chemical composition by weight percentage is: Si 5.5%, B0.04%, Zr 0.05%, C 0.007%, Mn 0.008%, P 0.005%, S 0.004%, N 0.002 %, O0.002%, balance Fe. At a temperature of 1200°C, after 210 minutes of heat preservation, air free forging was used to form a 45mm thick billet. The heating temperature of the slab hot rolling is 1180°C, and the holding time is 100min. Then, it is hot-rolled without lubrication on a two-roll reversible experimental hot rolling mill and hot-rolled to 3.0mm after 11 passes. The starting temperature is 1120°C, and the final The rolling temperature was 880°C, and then cooled to room temperature in air. Use 6% hydrochloric acid solution to pickle the hot-rolled plate, the pickling temperature is 60° C., and the pickling time is 15 minutes to remove the surface oxide scale.

[0037] Warm rolling is carried out by using a four-roll cold rolling mill, and the warm rolling process...

Embodiment 3

[0041] Vacuum induction furnace is used to cast high-silicon steel ingots, and its chemical composition by weight percentage is: Si 6.9%, B0.05%, Zr 0.06%, C 0.008%, Mn 0.007%, P 0.005%, S 0.004%, N 0.002 %, O0.002%, balance Fe. At a temperature of 1250°C, after 200 minutes of heat preservation, air free forging was used to form a 40mm thick billet. The heating temperature of the slab hot rolling is 1200°C, and the holding time is 90min. Then, it is hot-rolled without lubrication on a two-roll reversible experimental hot rolling mill and hot-rolled to 2.5mm by 12 passes. The starting temperature is 1150°C. The rolling temperature was 900°C, and then cooled to room temperature in air. The hot-rolled plate is pickled with 8% hydrochloric acid solution, the pickling temperature is 70° C., and the pickling time is 20 minutes to remove the surface oxide scale.

[0042] Warm rolling is carried out by using a four-roll cold rolling mill, and the warm rolling process is step-by-step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com