Rolling method for reducing surface cracking of TC4 titanium alloy smelted in an EB furnace

A titanium alloy, rolling direction technology, applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve the problem of inability to meet the requirements of the national standard, the high cost of titanium alloy sheets, and the cracked surface of the edge of the sheet. and other problems, to achieve uniform distribution of equiaxed structure, avoid surface cracks and edge cracks, and achieve the effect of fine equiaxed α phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

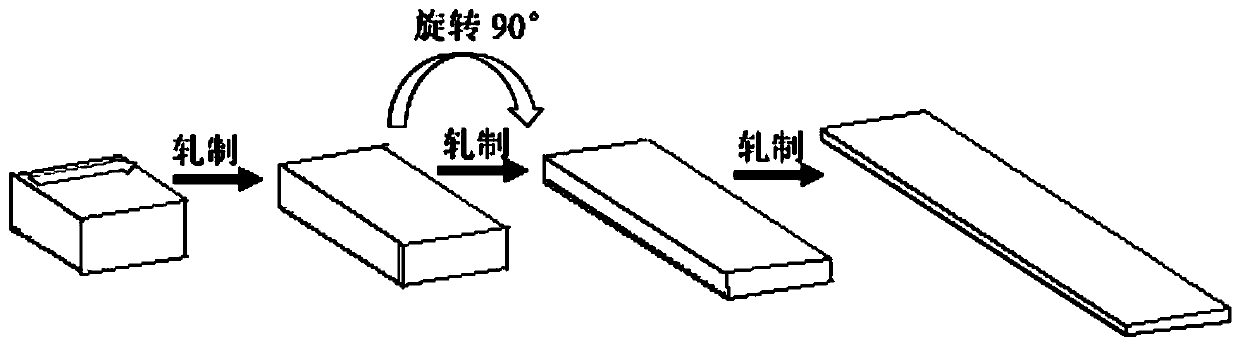

[0036] This embodiment reduces the rolling method of EB furnace smelting TC4 titanium alloy surface cracking, rolling process such as figure 1 As shown, the specific steps are as follows:

[0037] (1) For the TC4 titanium alloy of the present embodiment 1, the phase transition temperature of the alloy measured by the continuous heating method is 995° C.;

[0038] (2) Send the TC4 titanium alloy flat ingot to the heating furnace and heat it to 990°C with the furnace, and keep it warm for 50 minutes;

[0039] (3) The TC4 titanium alloy slab heated in step (2) is subjected to first-fire rolling, and the rolling speed is 1.1m / s, and is reciprocally rolled along the direction perpendicular to the grain growth direction, and the amount of deformation per pass is 16%. , 6 rolling passes, cumulative deformation 65%;

[0040] (4) Send the blank rolled in step (3) to a heating furnace and heat it to 970°C with the furnace, and keep it warm for 50 minutes;

[0041] (5) The billet afte...

Embodiment 2

[0049] This embodiment reduces the rolling method of EB furnace smelting TC4 titanium alloy surface cracking, rolling process such as figure 1 As shown, the specific steps are as follows:

[0050] (1) For the TC4 titanium alloy of the present embodiment 2, the phase transition temperature of the alloy measured by the continuous heating method is 995° C.;

[0051] (2) Send the TC4 titanium alloy flat ingot to the heating furnace and heat it to 980°C with the furnace, and keep it warm for 40 minutes;

[0052] (3) The TC4 titanium alloy flat ingot heated in step (2) is subjected to first-fire rolling, and the rolling speed is 0.8m / s, and is reciprocally rolled along the direction perpendicular to the grain growth direction, and the amount of deformation per pass is 21% , 4 rolling passes, accumulative deformation 61%;

[0053] (4) Send the billet after step (3) rolling to the heating furnace and heat it to 955°C with the furnace, and keep it warm for 40min;

[0054] (5) The bi...

Embodiment 3

[0062] This embodiment reduces the rolling method of EB furnace smelting TC4 titanium alloy surface cracking, rolling process such as figure 1 As shown, the specific steps are as follows:

[0063] (1) The TC4 titanium alloy of the present embodiment 3, adopting the continuous heating method to record the phase transition temperature of the alloy is 995°C;

[0064] (2) Send the TC4 titanium alloy flat ingot to the heating furnace and heat it to 970°C with the furnace, and keep it warm for 60 minutes;

[0065] (3) The TC4 titanium alloy flat ingot heated in step (2) is subjected to first-fire rolling at a rolling speed of 0.5m / s, reciprocatingly rolling along the direction perpendicular to the grain growth, and the amount of deformation per pass is 16% , 6 rolling passes, cumulative deformation 65%;

[0066] (4) Send the blank rolled in step (3) to a heating furnace and heat it to 940°C with the furnace, and keep it warm for 60 minutes;

[0067] (5) The billet after step (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com